Sound-absorbing insulation cotton and preparation method thereof and preparation method of sound-absorbing insulation mat

A technology of sound insulation cotton and sound insulation pad is applied in chemical instruments and methods, layered products, transportation and packaging, etc. It can solve the problems of complex production process, poor sound absorption and sound insulation effect, and high cost, and achieve convenient construction and strong sound insulation and sound absorption performance. , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

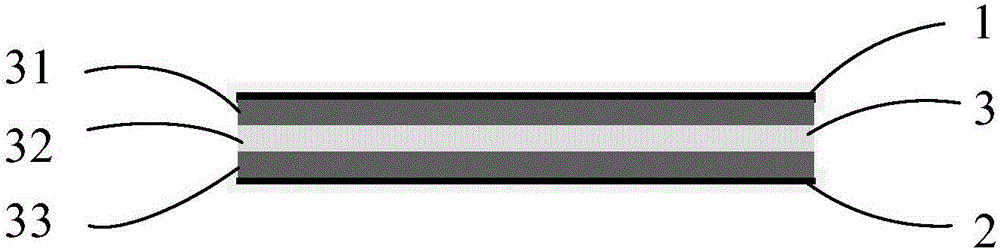

[0035] Such as figure 1 As shown, a sound-absorbing and sound-insulating cotton includes a top layer 1, a bottom layer 2 and a plurality of middle layers 3, and the top layer 1, a plurality of middle layers 3 and the bottom layer 2 are stacked sequentially from top to bottom, and the top layer 1 and the bottom layer 2 are both It is PP grid cloth, and the plurality of intermediate layers 3 are all made of mixing PP fibers and PET fibers.

[0036] Preferably, three intermediate layers 3 are provided, and the three intermediate layers 3 are respectively a first intermediate layer 31, a second intermediate layer 32 and a third intermediate layer 33, and the first intermediate layer 31 is connected to the second intermediate layer 33. The proportions of PP fibers and PET fibers in the three middle layers 33 are consistent.

[0037] Preferably, the ratio of PP fibers to PET fibers in the first middle layer 31 is 1:1; the ratio of PP fibers to PET fibers in the second middle layer ...

Embodiment 2

[0045] A preparation method of sound-absorbing and sound-insulating cotton, comprising the steps of:

[0046] Step S1. Lay the PP grid cloth into rolls, and divide it into the PP grid cloth at the bottom and the PP grid cloth at the top;

[0047] Step S2. Put PP and PET into the meltblown machine according to the mass ratio, heat and filter, and output the first mixture and the second mixture according to the designed ratio. The ratio of the first mixture PP to PET is 1:1, and the second The ratio of the secondary mixture PP to PET is 2:1;

[0048]Step S3. Feed the PP grid cloth at the bottom into the net forming machine, continuously spray the first mixture on the bottom PP grid cloth to the set thickness in the net forming machine, and replace the second mixture for spinning , to reach the set thickness, and then replace the first mixture for spinning to form a network structure of PP fibers and PET fibers, and cover the top PP mesh cloth on the network structure of PP fibe...

Embodiment 3

[0050] A method for preparing a sound-absorbing and sound-insulating pad, comprising the following steps: placing the sound-absorbing and sound-insulating cotton under a hot mold with an edge temperature of 200-280° C. pad.

[0051] This device belongs to fibrous porous sound-absorbing material, which has a three-dimensional network continuous porous structure. Compared with ordinary sound-absorbing cotton, the sound-absorbing cotton fiber diameter of this device is smaller, and the number of fibers per unit is more. There are more pores and gaps, and these pores are smaller; and the gradient structure adopted makes the material light in weight, excellent in gradient sound insulation and sound absorption performance, strong in decoration, and convenient in construction; it solves the problem of poor quality in the current sound-absorbing and sound-insulating materials for vehicles. Heavy, poor sound-absorbing effect, no shock-absorbing features.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com