Preparation method of foamed aluminum sound-absorbing and sound-insulating composite material

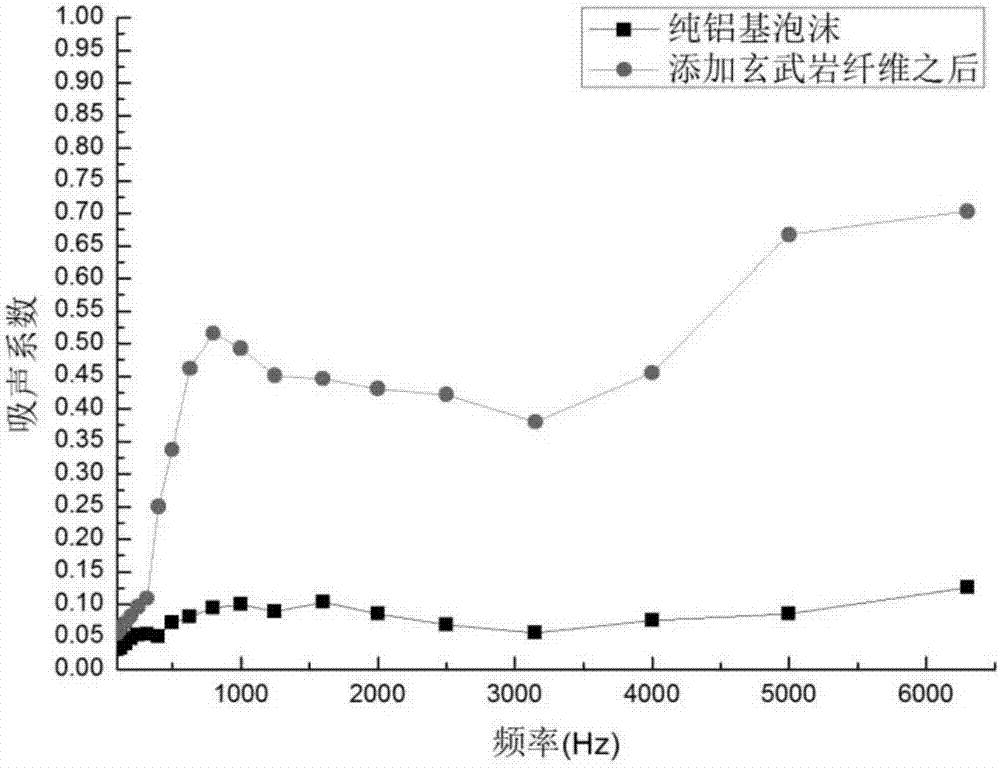

A composite material and foamed aluminum technology, which is applied in the field of preparation of foamed aluminum sound-absorbing and sound-insulating composite materials, can solve the problems of reduced sound-absorbing and sound-insulating properties, easy cracks in the pore walls, and small size range, etc. The effect of extensive and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

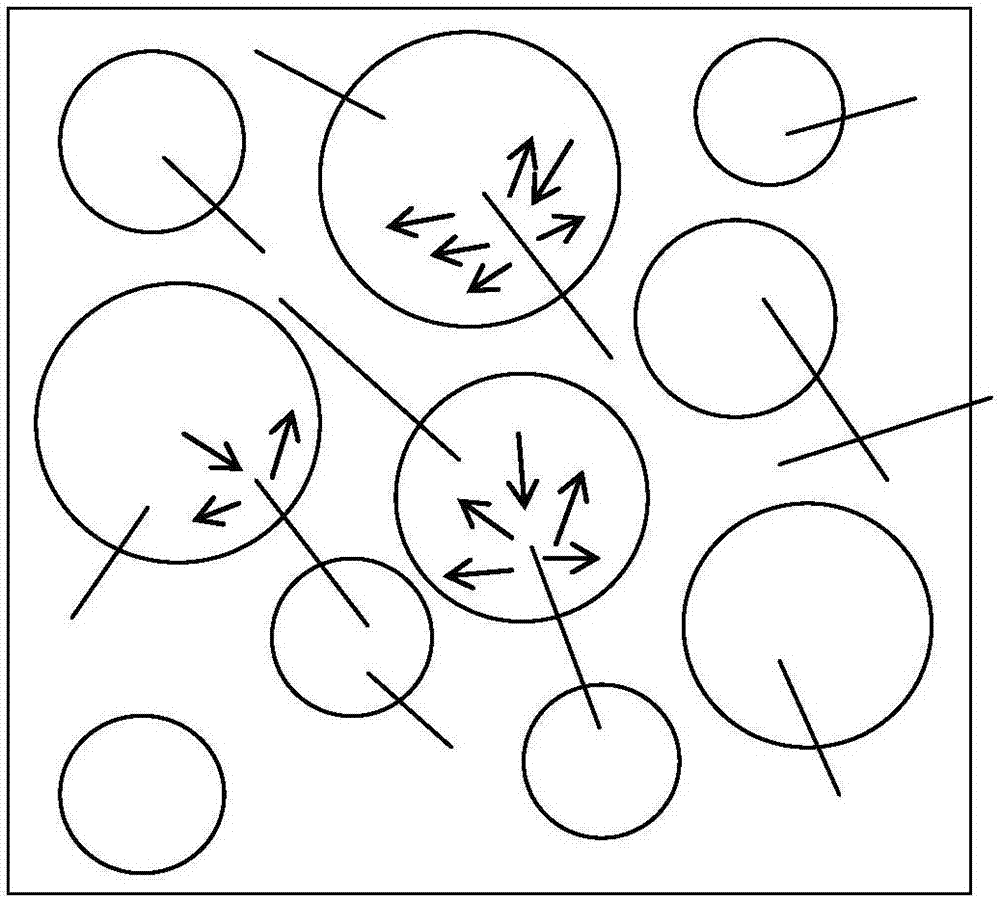

Method used

Image

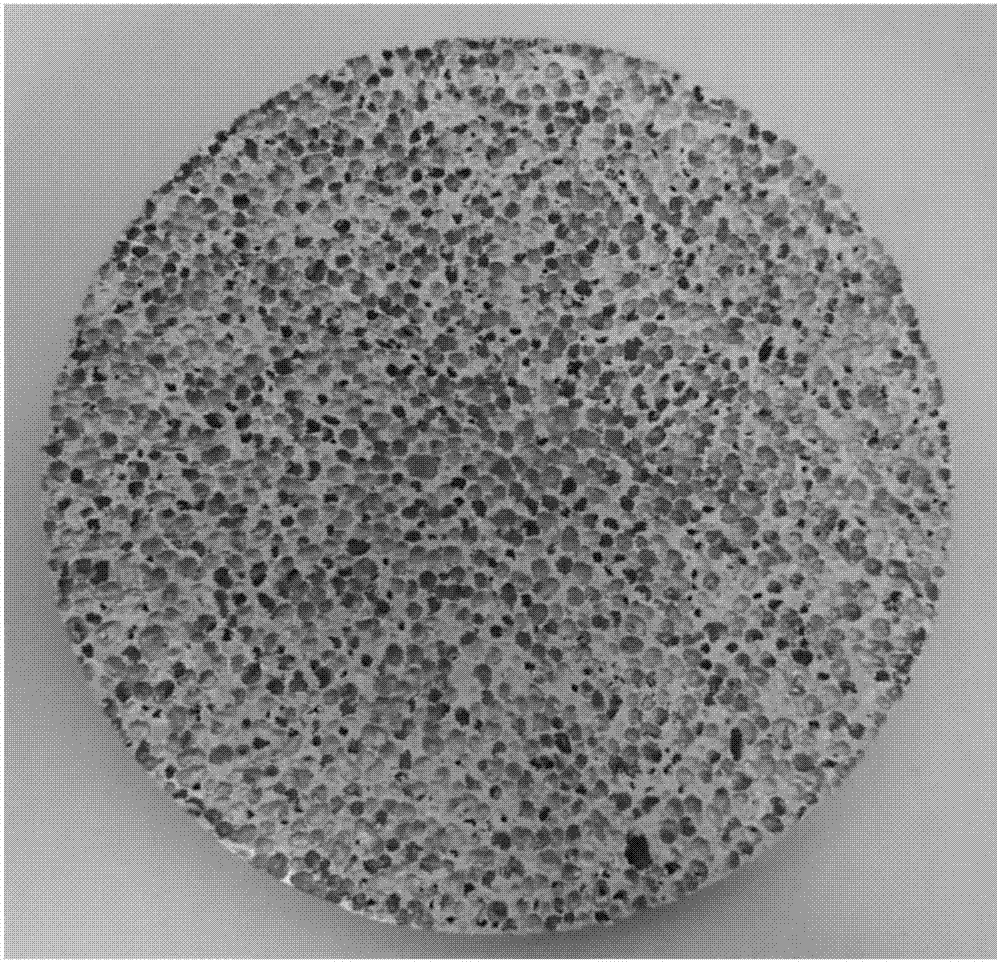

Examples

Embodiment 1

[0037] In the first step, heat-treat the purchased basalt chopped fibers at 680°C for 25 minutes, take them out and air-cool them, and pack them into bags for weighing in experiments;

[0038] The second step is to cut commercial pure aluminum ingots (purity is 99.5% by mass percentage of industrial pure aluminum) into aluminum blocks, weigh 810g of aluminum blocks and put them in the crucible, start the resistance furnace to raise the temperature to 700°C, keep the temperature for 45min, and make the crucible Melt the aluminum block in the furnace and maintain a uniform temperature to obtain an aluminum melt;

[0039] In the third step, put the stirring paddle into the aluminum melt to preheat, and adjust the temperature of the resistance furnace to 680°C. After the temperature of the aluminum melt is stable, add the pre-wrapped aluminum foil to the aluminum melt obtained in the second step. Thickener metal calcium particles (particle size: 1-3mm) with 2% weight of the alumin...

Embodiment 2

[0045] The first step is to heat-treat the purchased basalt chopped fibers at 700°C for 30 minutes, take them out and air-cool them, and pack them into bags for weighing in experiments;

[0046] The second step is to cut commercial pure aluminum ingots (purity is 99.5% by mass percentage of industrial pure aluminum) into aluminum blocks, weigh 850g of aluminum blocks and put them in the crucible, start the resistance furnace to raise the temperature to 710°C, keep the temperature for 50min, and make the crucible Melt the aluminum block in the furnace and maintain a uniform temperature to obtain an aluminum melt;

[0047] In the third step, put the stirring paddle into the aluminum melt to preheat, and adjust the temperature of the resistance furnace to 700°C. After the temperature of the aluminum melt is stable, add the pre-wrapped aluminum foil to the aluminum melt obtained in the second step. Thickener metal calcium particles (particle size: 1-3mm) of 3% of the weight of the...

Embodiment 3

[0051] The first step is to heat-treat the purchased basalt chopped fibers at 750°C for 40 minutes, take them out and air-cool them, and pack them into bags for weighing in experiments;

[0052] In the second step, the commercial pure aluminum ingot (purity is 99.5% by mass percentage of industrial pure aluminum) is cut into aluminum blocks, and 880g of aluminum blocks are weighed and put into the crucible, and the resistance furnace is started to raise the temperature to 730°C, and the temperature is kept for 60min to make the crucible Melt the aluminum block in the furnace and maintain a uniform temperature to obtain an aluminum melt;

[0053] In the third step, put the stirring paddle into the aluminum melt to preheat, adjust the temperature of the resistance furnace to 690°C, and after the temperature of the aluminum melt is stable, add the pre-wrapped aluminum foil to the aluminum melt obtained in the second step Thickening agent calcium metal particles (1-3mm in particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com