A New Bottom Structure of Fluidized Chlorination Furnace Without Sieve Plate

A technology of boiling chlorination furnace and bottom structure, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problem of hanging on the lower edge of the gas distributor or falling into the distributor, affecting the normal operation of the sieveless boiling chlorination process It is difficult to overcome the problems such as blockage of the gas outlet of the trachea, so as to extend the single working time, facilitate continuous and efficient production, and reduce the number and time of furnace shutdowns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the drawings. Among them, descriptive terms such as up, down, left, and right are used for the description, which aims to help readers understand, and are not intended to limit.

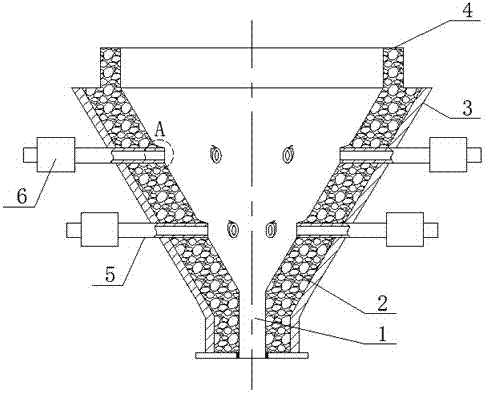

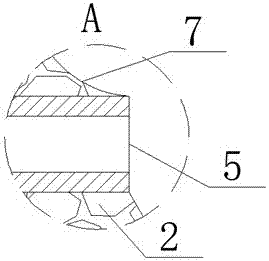

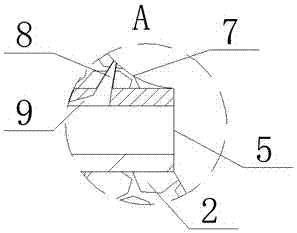

[0055] When implementing: Figure 1 to Figure 2 As shown, a new type of bottom structure of a sieve-free boiling chlorination furnace includes a shell 3 with a funnel shape. The bottom of the shell 3 has a slag discharge port 1, and the inner side of the shell 3 has an inner lining 2. And the inner liner 2 is made of high-temperature and corrosion-resistant materials; the outer shell 3 is sealed and fixedly provided with a circular nozzle 5, and the end face of the air nozzle of the circular nozzle 5 is a vertical circle. The air jet has an exposed part exposed outside the inner liner 2 and the lower end of the exposed part is flush with the surface of the inner liner 2.

[0056] In implementation, it is preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com