A kind of sludge heavy metal resource recovery extraction system and its extraction method

An extraction system and heavy metal technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve harsh operating conditions, high safety risks, strong acids, and large consumption of oxidants and reducing agents, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

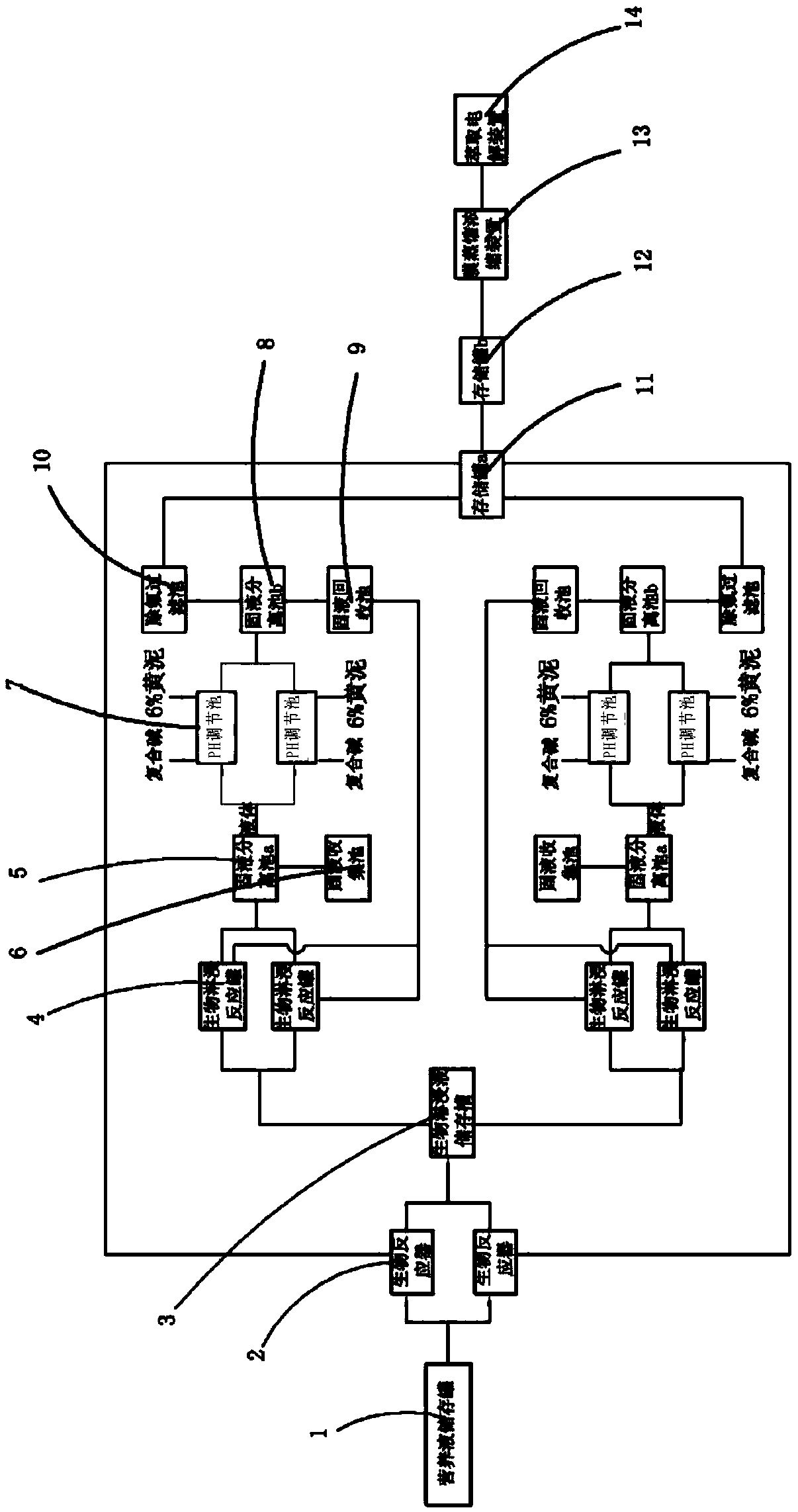

[0029] Examples, see attached figure 1 , a sludge heavy metal resource extraction system, including a culture solution storage tank 1, a mixture of sulfur and ferrous sulfide is housed in the culture solution storage tank, the volume of the culture solution storage tank in this embodiment is 5m 3 ; The liquid outlet of the culture fluid storage tank is connected with two groups of bioreactors 2 in parallel, and the volume of each group of bioreactors is 60m 3 , the bioreactor is filled with water and microorganisms, the mixture in the culture liquid storage tank enters the bioreactor, and reacts with the water and microorganisms in the bioreactor for 5 hours, which can convert sulfur and pyrite into biologically active acids , using the active acid can effectively wash the heavy metals in the hazardous solid waste; the liquid outlets of the two sets of bioreactors are respectively connected to the biological leachate storage tank 3, and the volume of the biological leachate st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com