Detection of leakage in an air system of a motor vehicle

一种汽车、废气的技术,应用在装料系统、空气质量改善、排气处理装置的电控等方向,能够解决废气质量流足够的散热低、颗粒过滤器损坏等问题,达到减少氧气、改善使用寿命、防止损坏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

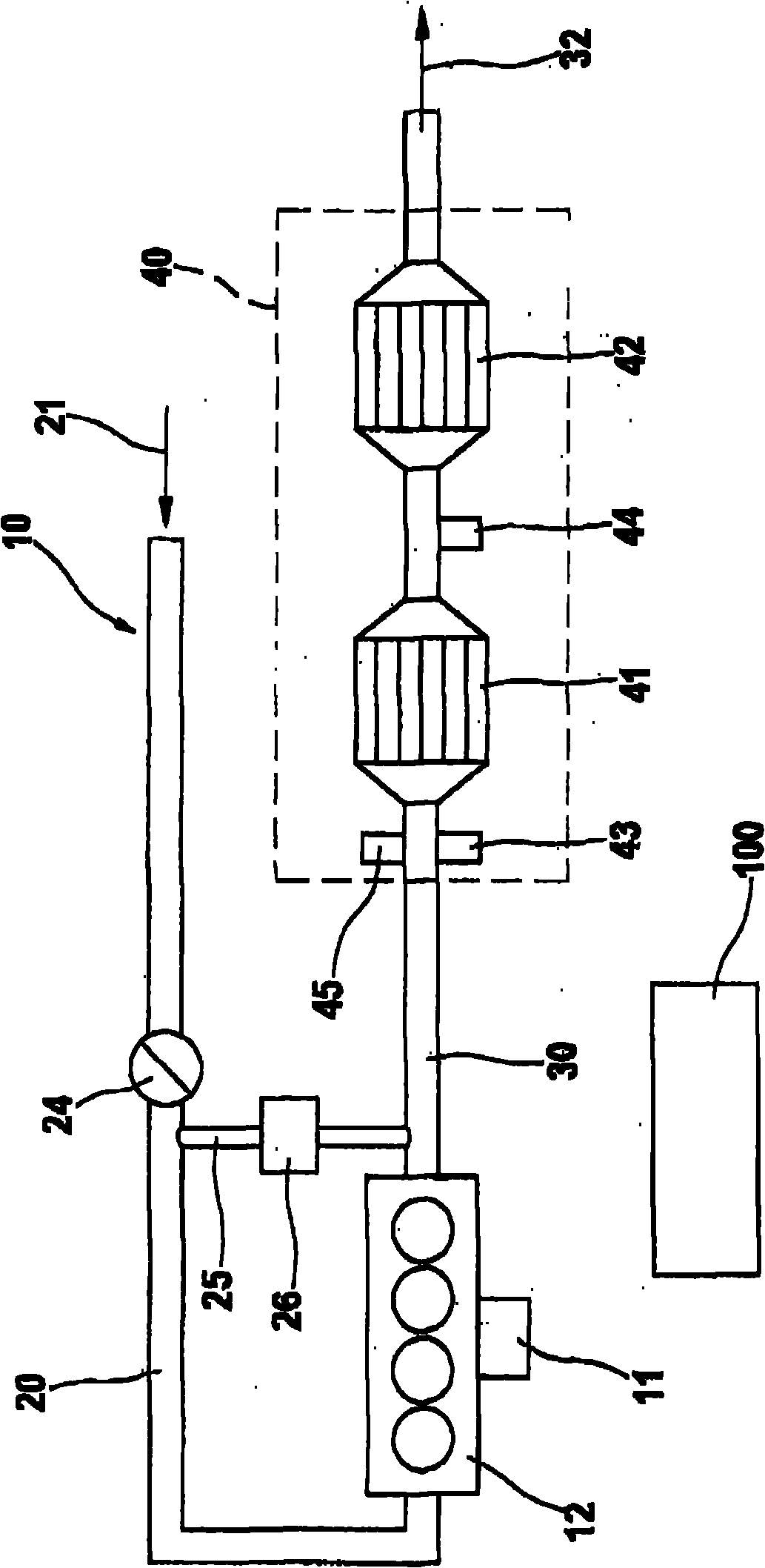

[0021] figure 1 A schematic diagram shows an internal combustion engine 10 in the form of a diesel engine with a cylinder block 12 , a fuel metering system 11 , an intake duct 20 conducting an intake air flow 21 , and an exhaust duct 30 conducting an exhaust gas flow 32 of the internal combustion engine 10 . A throttle valve 24 is arranged in the intake passage 20 . The exhaust gas recirculation channel 25 connects the intake channel 20 with the exhaust gas channel 30 at least briefly via an exhaust gas recirculation valve 26 . Behind the cylinder block 12 in the flow direction of the exhaust gas flow 32 , a first oxygen sensor 43 , a fuel supply channel 45 (optional), a diesel oxidation catalytic converter are shown as components of an exhaust gas aftertreatment system 40 associated with the internal combustion engine 10 . form of an oxidation catalyst 41 , a second oxygen sensor 44 and a diesel particulate filter 42 . The exhaust system of a diesel engine can also be equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com