Preparation method of novel PVC (polyvinyl chloride) heat stabilizer

A heat stabilizer and a new type of technology, applied in the field of preparation of new PVC heat stabilizers, can solve the problems of low alkali capacity, poor lipophilicity and unstable quality of alkaline clay, and achieve shortened production process cycle and good compatibility. , the effect of easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

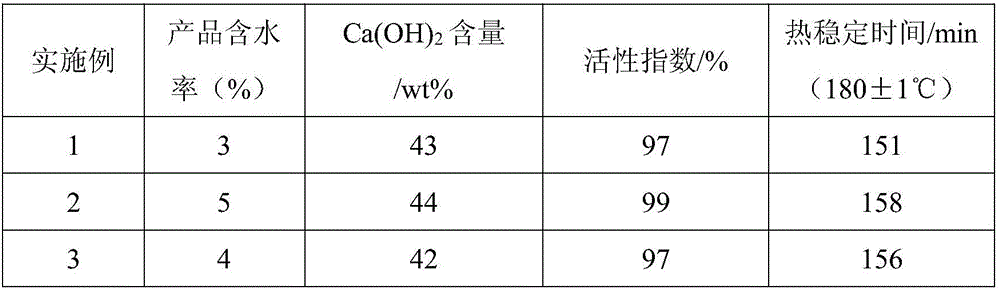

Examples

preparation example Construction

[0037] A preparation method of a novel PVC heat stabilizer, comprising the following steps:

[0038] S1: Mix bentonite and activated clay wastewater with a concentration of 10%-16% in a weight ratio of 1.6-2.2:10-14, and stir evenly at a rotating speed of 200-500r / min to obtain a slurry material A;

[0039] S2: Add the slurry material A prepared in step S1 to the inorganic mixed acid with a concentration of 11%-20%, and the mixed inorganic acid is hydrochloric acid with a concentration of 25-30wt%, carbonic acid with a concentration of 32-36wt%, and a concentration of 32-36wt%. 18-20wt% phosphoric acid is a mixed acid composed of 3-6:3-5:2-3 by volume, the weight ratio of slurry material A to inorganic mixed acid is 1-3.2:4-16, and the rotating speed is 200- Add sodium disulfide and stir at 550r / min, the weight ratio of sodium disulfide to slurry material A is 1-2:50-150, heat to 82-93°C, and keep at 82-93°C for 1.2-3.2 h, making slurry material B;

[0040] S3: press-filter ...

Embodiment 1

[0050] A preparation method of a novel PVC heat stabilizer, comprising the following steps:

[0051] S1: Mix bentonite and activated clay wastewater with a concentration of 12% at a weight ratio of 2:12, and stir evenly at a speed of 400r / min to obtain a slurry material A;

[0052] S2: Add the slurry material A prepared in step S1 into the inorganic mixed acid with a concentration of 15%, and the inorganic mixed acid is hydrochloric acid with a concentration of 28wt%, carbonic acid with a concentration of 34wt%, and phosphoric acid with a concentration of 19wt% by volume Mixed acid composed of 4:3:2, the weight ratio of slurry material A to inorganic mixed acid is 2:10, and sodium disulfide is added under the condition of rotating speed of 400r / min to stir, the weight of sodium disulfide and slurry material A The ratio is 2:120, heated to 85°C, and kept at 85°C for 2.5h to obtain slurry material B;

[0053] S3: press-filter the slurry material B prepared in step S2 under a pr...

Embodiment 2

[0062] A preparation method of a novel PVC heat stabilizer, comprising the following steps:

[0063] S1: Mix bentonite and activated clay wastewater with a concentration of 16% at a weight ratio of 2.2:14, and stir evenly at a rotating speed of 500r / min to obtain slurry material A;

[0064] S2: Add the slurry material A prepared in step S1 into the inorganic mixed acid with a concentration of 20%, and the inorganic mixed acid is hydrochloric acid with a concentration of 30wt%, carbonic acid with a concentration of 36wt%, and phosphoric acid with a concentration of 20wt% by volume Mixed acid composed of 6:5:3, the weight ratio of slurry material A to inorganic mixed acid is 3.2:16, add sodium disulfide and stir under the condition of rotating speed of 550r / min, the weight of sodium disulfide and slurry material A The ratio is 2:150, heated to 93°C, and kept at 93°C for 1.2h to prepare slurry material B;

[0065] S3: press-filter the slurry material B prepared in step S2 under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com