Anti-creasing agent used for cellulosic fiber fabric and its synthesizing method

A technology of cellulose fiber and anti-wrinkle agent, applied in the field of anti-wrinkle finishing agent and its synthesis, can solve the problems of reduced dye uptake rate of anionic dyes, easy environmental pollution, increased brittleness, etc., and achieves easy control of the reaction process and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Take by weighing 0.5 moles (i.e. 65 grams) of itaconic acid, and weigh itaconic acid, ethanol, diethanolamine according to the ratio of substances to be 1: 0.5: 0.5;

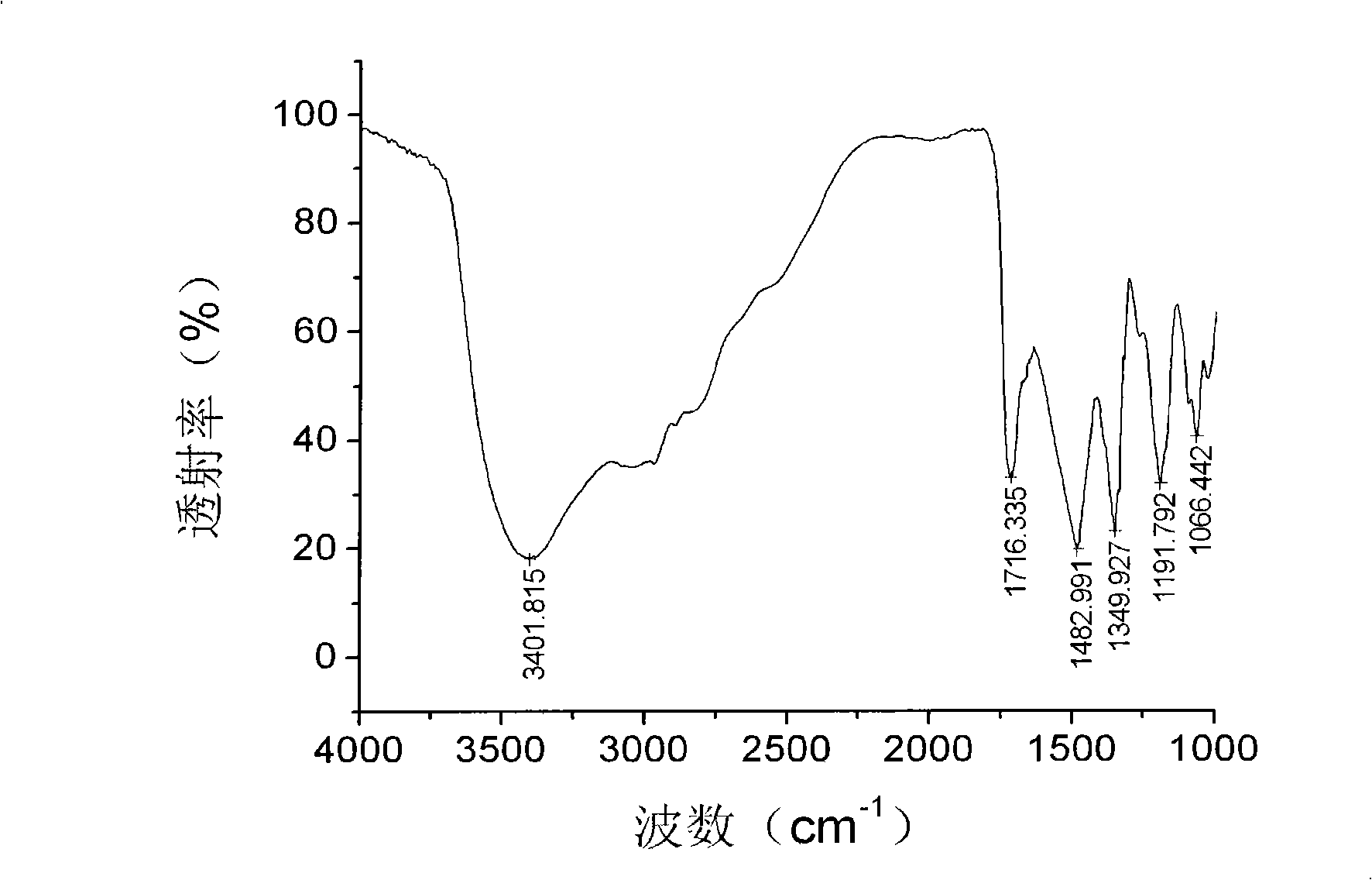

[0052]First, add 65 grams of itaconic acid into the reaction vessel, then add 195 grams of deionized water, stir, gradually raise the temperature to 75°C, add initiator ammonium persulfate accounting for 1% of the mass of itaconic acid, and react at 85°C for 2 hours , to obtain the intermediate product (i); add 0.25 moles (11.5 grams) of ethanol to the reaction vessel containing the intermediate product (i), stir, and slowly add dropwise the concentrated sulfuric acid that accounts for intermediate product (i) mass 3% after 85 ° C , turn on the condensing device, and keep warming up to 130°C, keep the heat for 3 hours, if the acid value of the product remains unchanged, it means that the reaction has reached the end point, and the intermediate product (ii) is obtained; then add 0.25 moles (26.25 grams) of...

Embodiment 2

[0061] Take by weighing 0.5 moles (i.e. 65 grams) of itaconic acid, and weigh itaconic acid, methyl alcohol, and dipropanolamine according to the ratio of substances to be 1: 0.5: 0.5;

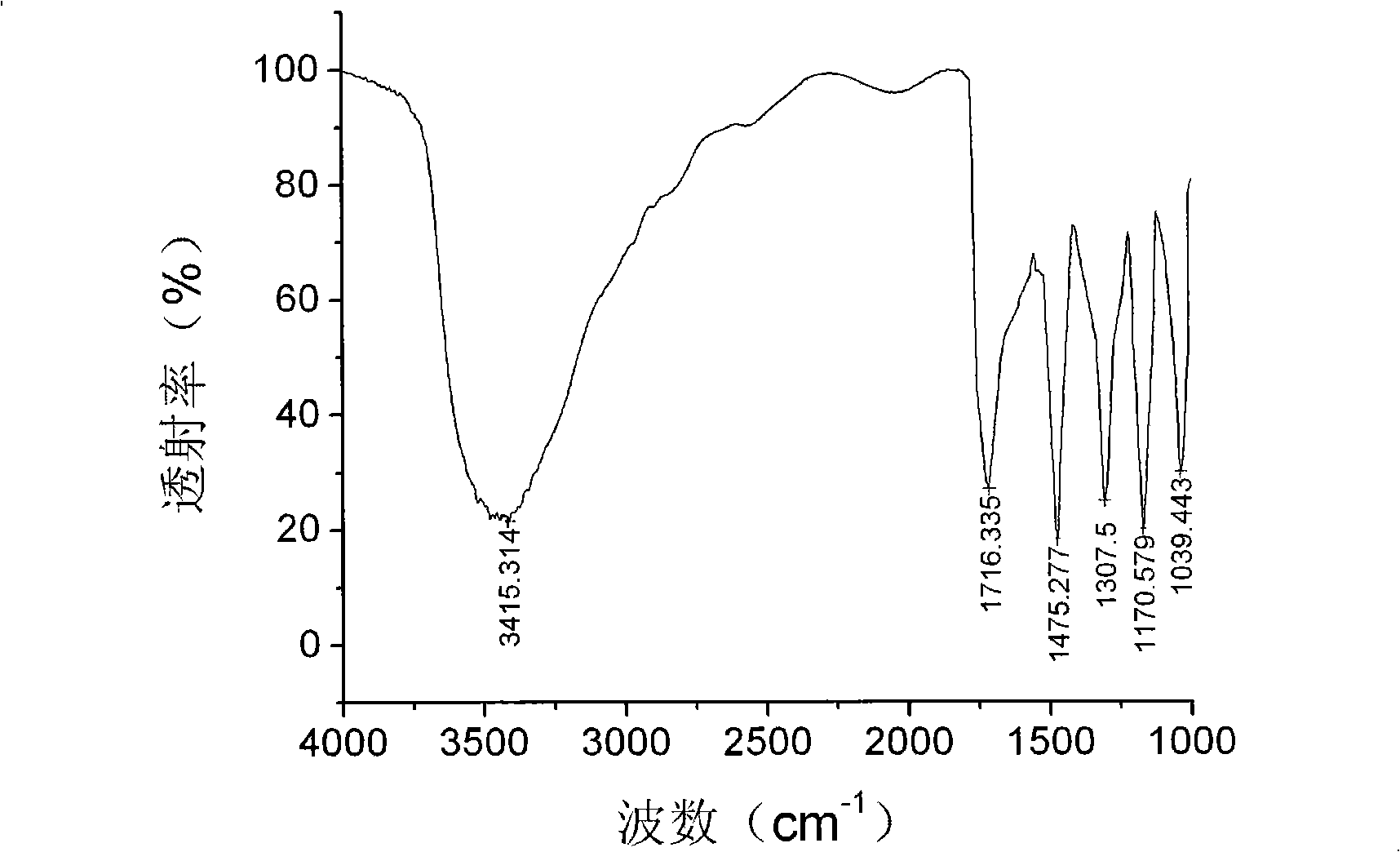

[0062] First, 65 grams of itaconic acid were added to the reaction vessel, then 195 grams of deionized water was added, stirred, and the temperature was gradually raised to 75°C, and the initiator ammonium persulfate accounting for 2% of the mass of itaconic acid was added, and reacted at 82°C for 2.5 h, to obtain the intermediate product (i); add 0.25 moles (8 grams) of methyl alcohol in the reaction vessel that fills the intermediate product (i), stir, slowly add dropwise the concentrated product that accounts for intermediate product (i) mass 5% after 80 ℃ Sulfuric acid, turn on the condensing device, and continue to heat up to 120°C, then keep warm for 2.5 hours, if the acid value of the product remains unchanged, it means that the reaction has reached the end, and the intermediate product ...

Embodiment 3

[0071] Take by weighing 0.5 moles (i.e. 65 grams) of itaconic acid, and weigh itaconic acid, propanol, and diisopropanolamine according to the ratio of substances to be 1: 0.5: 0.5;

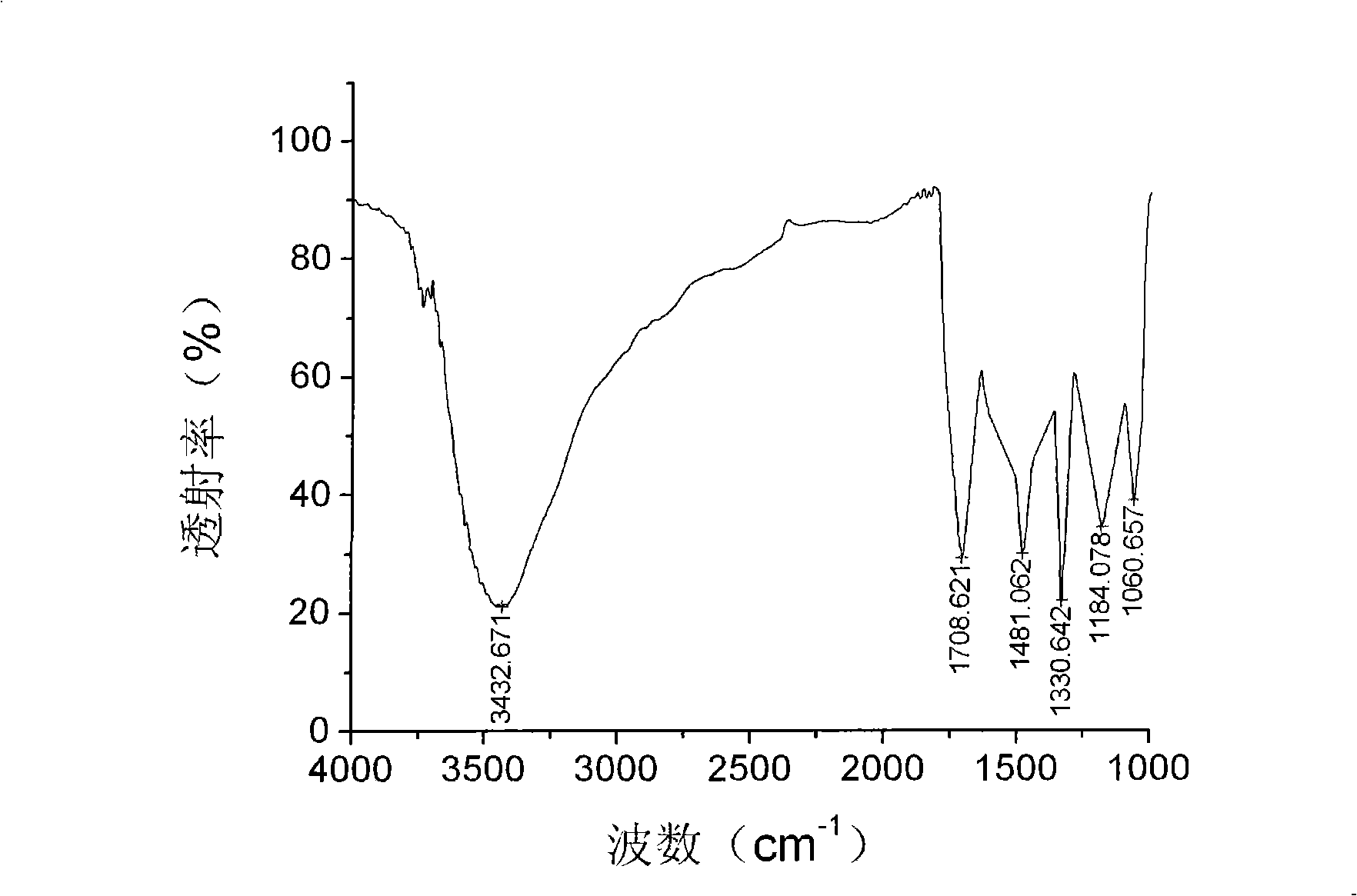

[0072] First, add 65 grams of itaconic acid into the reaction vessel, then add 195 grams of deionized water, stir, gradually raise the temperature to 75°C, add initiator ammonium persulfate accounting for 3% of the mass of itaconic acid, and react at 80°C for 3 hours , to obtain the intermediate product (i); add 0.25 moles (15.25 grams) propanol in the reaction vessel that fills the intermediate product (i), stir, slowly add dropwise the concentrated product that accounts for intermediate product (i) quality 4% after 90 ℃ Sulfuric acid, turn on the condensing device, and keep warming up to 140°C, keep the heat for 2 hours, if the acid value of the product remains unchanged, it means that the reaction has reached the end, and the intermediate product (ii) is obtained; then put it into the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com