Application of polymer sealant in bridge expansion joint device by serving as sealant

A telescopic device and sealant technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of short service life, water leakage, easy blockage, etc., and achieve the effect of reducing economic losses, good sealing performance, and delaying aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as figure 1 , figure 2 As shown, the application of polymer sealant as a sealant in bridge expansion devices:

[0030] The polymer sealant is polysulfide sealant (two-component polysulfide sealant, purchased from Hengshui Dayu Engineering Rubber Technology Development Co., Ltd.); the bridge expansion device is a steel expansion device; the backing material is polyethylene closed-cell foam ( Closed-cell polyethylene foam board was purchased from Hengshui Aotai Engineering Rubber Co., Ltd.).

[0031] The bridge expansion joint structure includes an expansion joint and a bridge expansion device. The gap between two adjacent beams forms an expansion joint. The bridge expansion device includes a profiled steel 1a symmetrically arranged on the sides of the two beams. The profiled steel 1a is provided with an opening Facing the notch joint of the expansion joint, the section steel 1a on both sides is connected into one body through the sealant strip 2a laid in the notc...

Embodiment 2

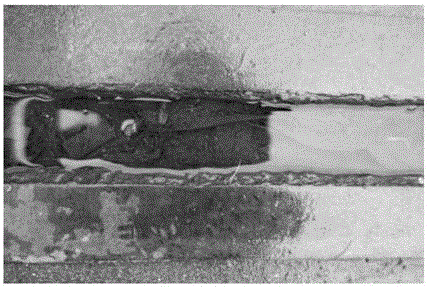

[0042] Such as image 3 As shown, the application of polymer sealant as a sealant in bridge expansion devices:

[0043] The polymer sealant is polyurethane sealant (polyurethane road caulk, purchased from Guangzhou Huaguan Engineering Co., Ltd., Chinese Academy of Sciences); the bridge expansion device is a modular expansion device; the backing material is polyethylene closed-cell foam (polyethylene closed-cell foam). Porous foam board was purchased from Hengshui Aotai Engineering Rubber Co., Ltd.).

[0044] The bridge expansion joint structure includes an expansion joint and a bridge expansion device. The gap between two adjacent beams forms an expansion joint. The bridge expansion device includes a profiled steel 1b symmetrically arranged on the sides of the two beams. The profiled steel 1b is provided with an opening Facing the notch joint of the expansion joint, the section steel 1b on both sides is connected into one body through the sealant strip 2b laid in the notch jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com