Four-axis shearing crusher

A shearing and crusher technology, applied in mechanical equipment, grain processing, fluid pressure actuation devices, etc., can solve the problems of complex composition of crushed materials, increase of the total weight of the whole machine, high power of the whole machine, etc., and achieve high torque , reduce the total weight, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

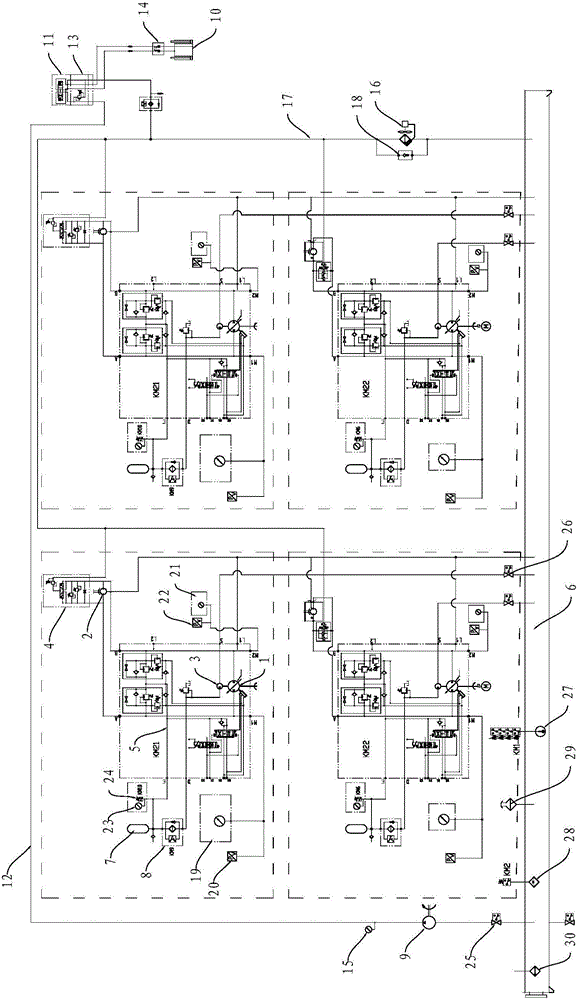

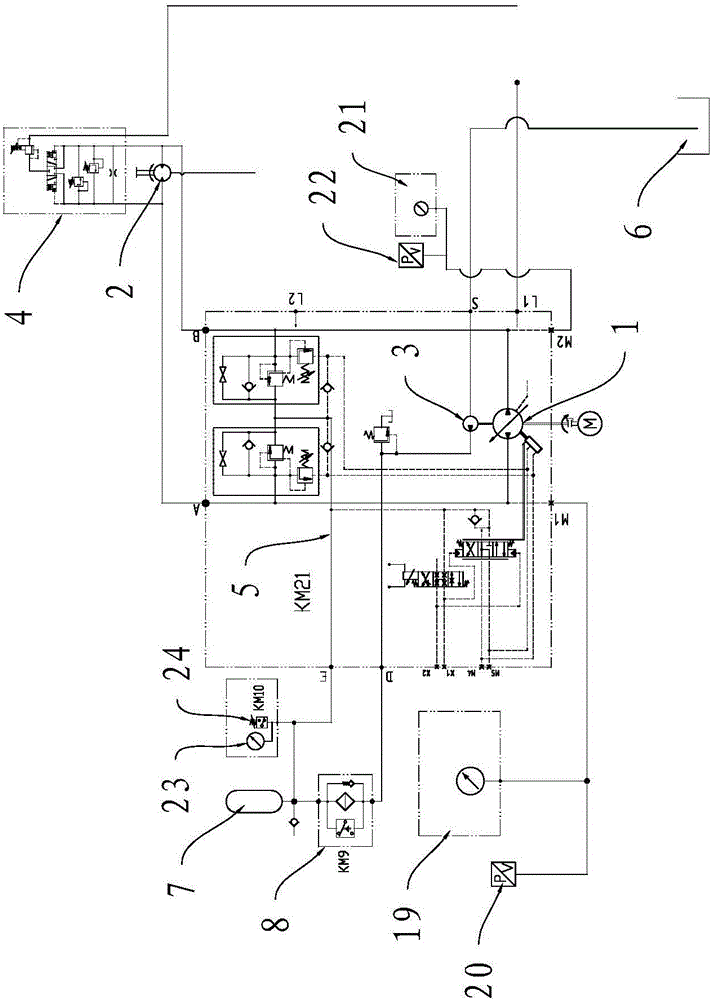

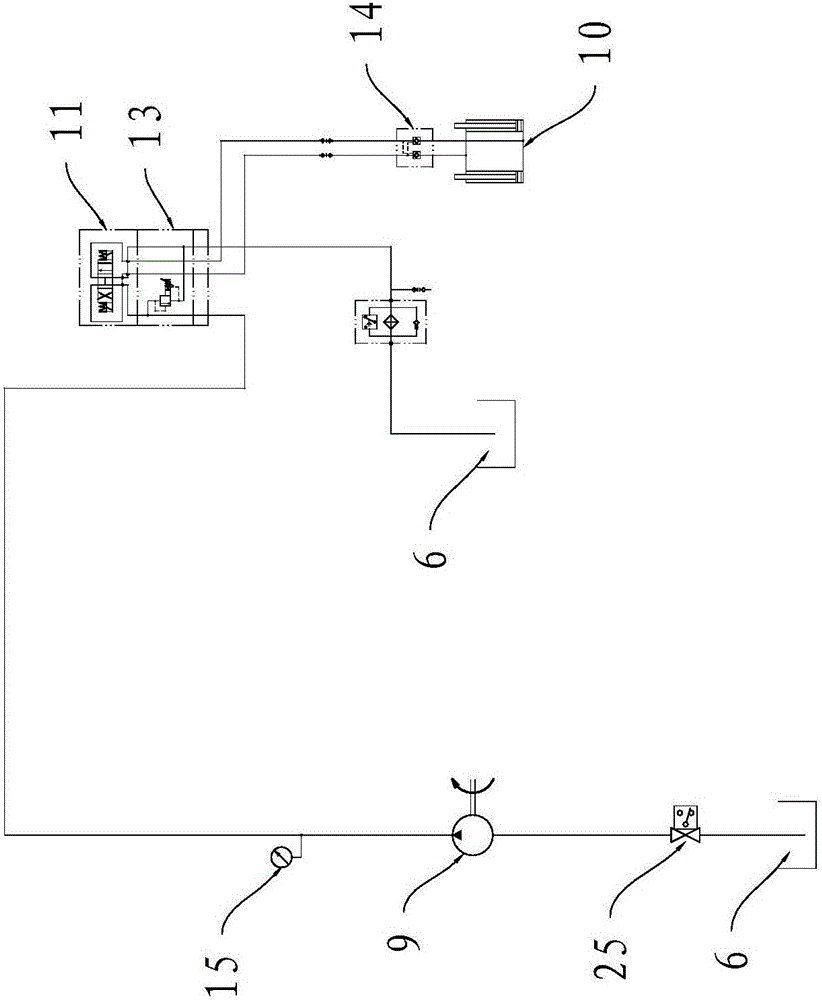

[0024] Such as Figure 1-4 As shown, the four-shaft shearing crusher of the present invention includes a housing, a cutter shaft installed in the housing, a discharge door arranged on the housing, and a hydraulic system; the hydraulic system includes a variable pump-quantitative motor closed hydraulic system, Gear pump-hydraulic cylinder subsystem, cooling system and hydraulic oil tank 6; variable pump-quantitative motor closed hydraulic system has four sets, such as figure 1 , the four dotted rectangular boxes show four variable pump-quantitative motor closed hydraulic systems.

[0025] Variable pump-quantitative motor closed hydraulic system includes variable pump 1, hydraulic motor 2, charging pump 3, flushing valve 4 and the first hydraulic pipeline 5, variable pump 1, hydraulic motor 2, charging pump 3 and flushing valve 4 all pass through the first A hydraulic pipeline 5 is connected; the oil outlet of the variable pump 1 is connected with the oil inlet of the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com