A kind of end face sealing lng filling port with positioning structure

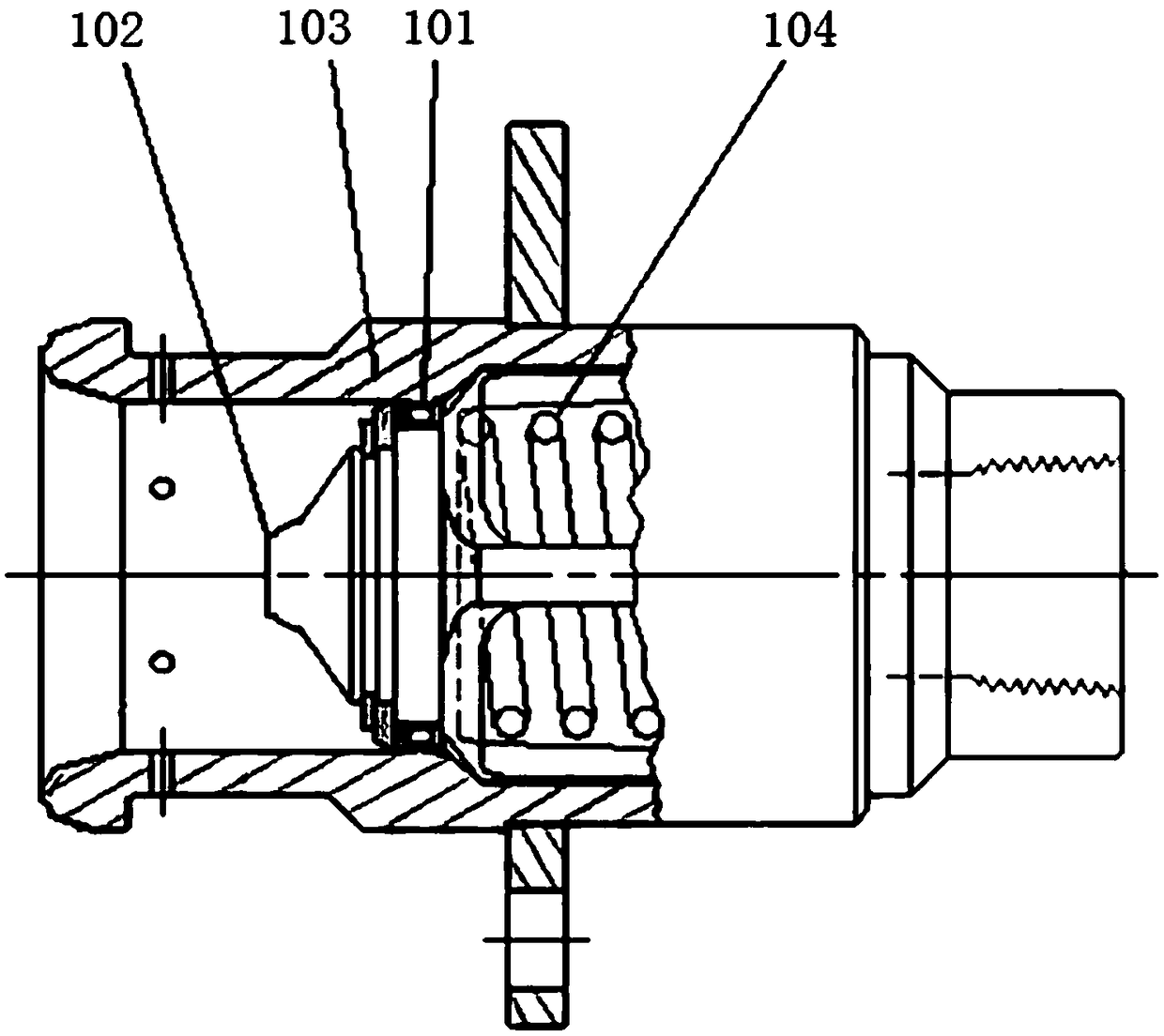

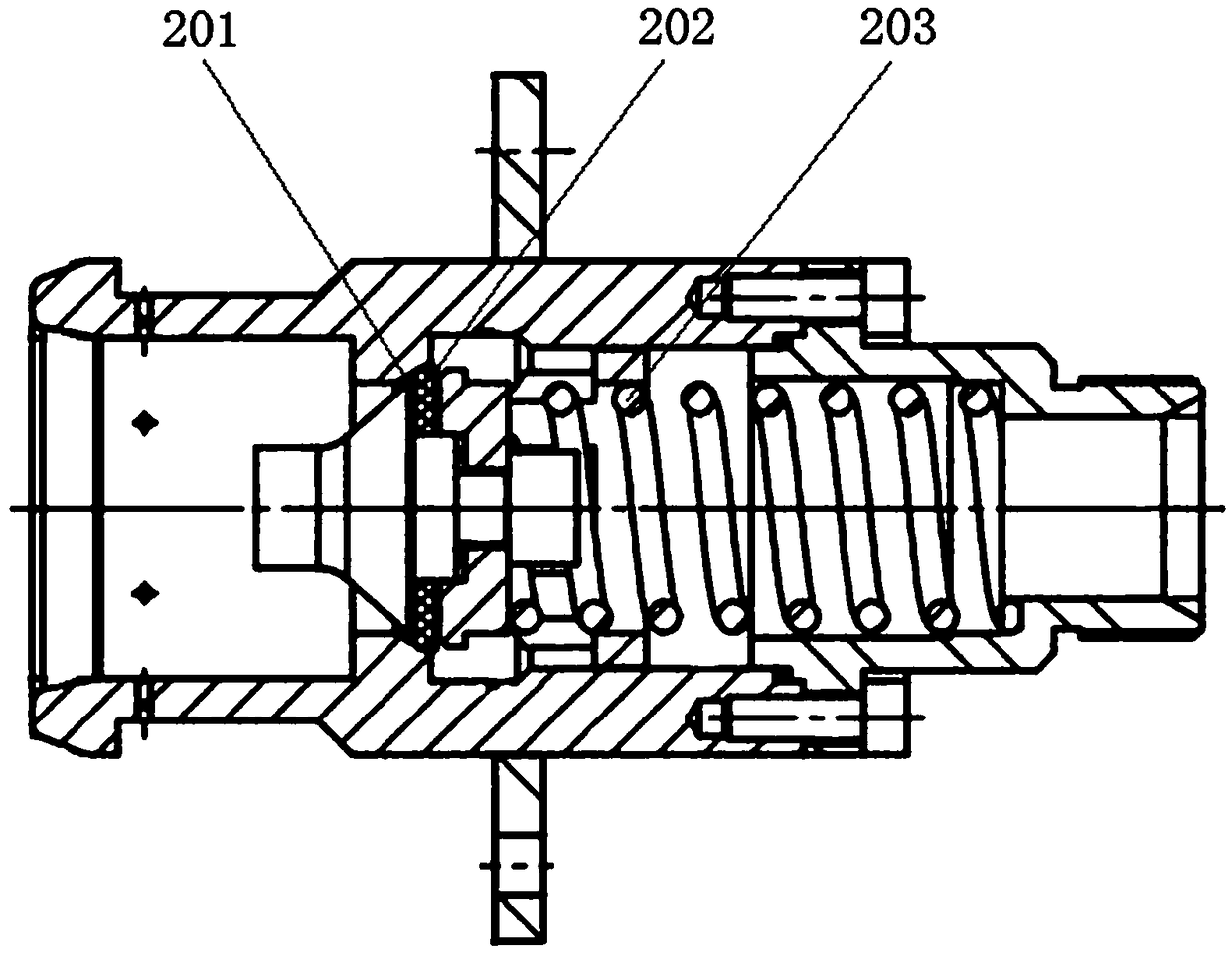

A technology of end face sealing and positioning structure, which is applied in the field of LNG filling port, can solve unevenness, the direction of spring force is biased in the direction of the valve body axis, the compression spring 203 is prone to tilt and shake, and the sealing method lacks a positioning guarantee structure and other issues to achieve the effect of increasing flow rate, eliminating the risk of seal failure, and improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

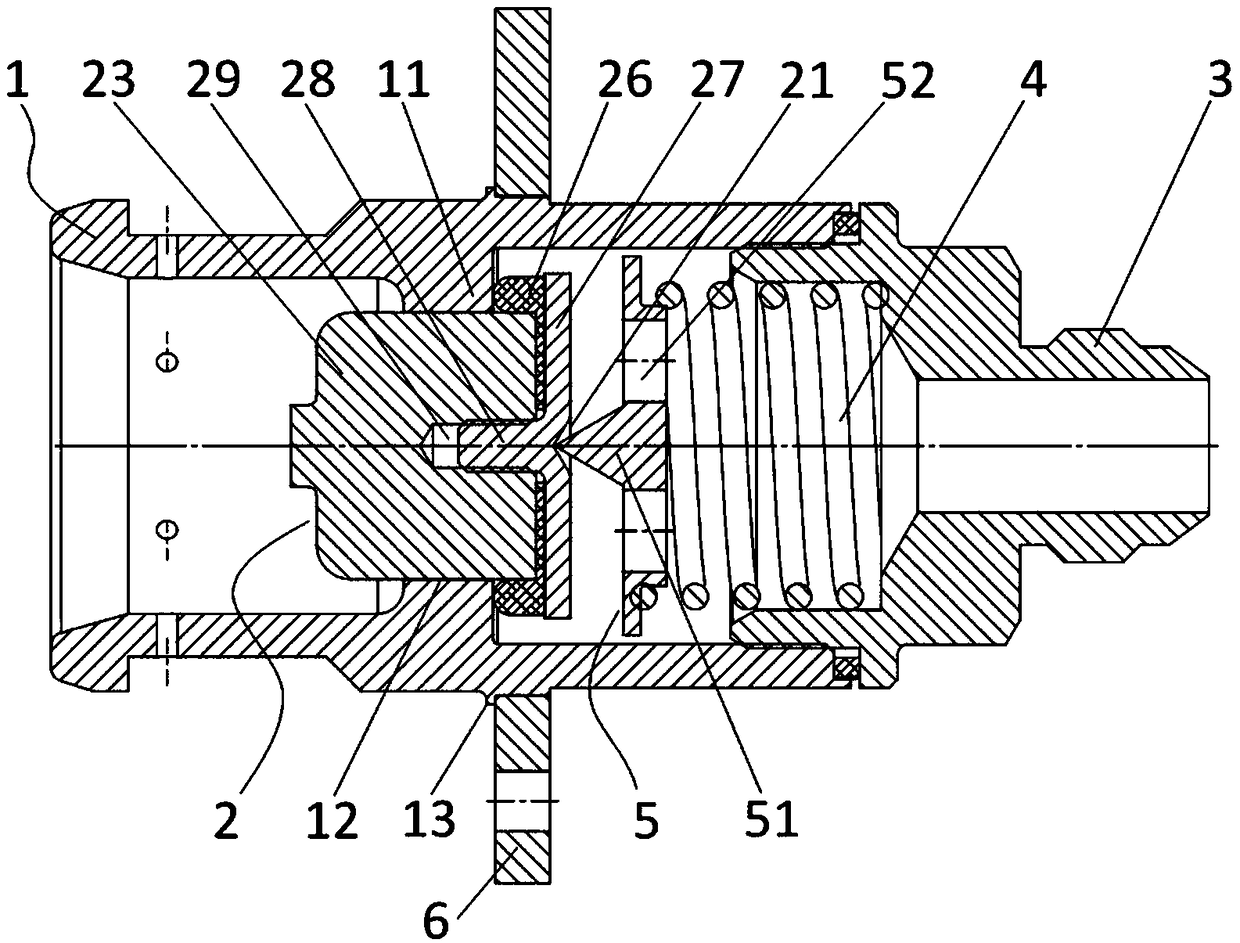

[0028] A first embodiment of an end-face-sealed LNG filling port with a positioning structure of the present invention, such as Figure 3 to Figure 5As shown, it includes a valve body 1, a valve core 2 arranged in the hollow cavity of the valve body 1, an end cover 3 connected to the end of the valve body 1, and a spring 4 arranged between the valve core 2 and the end cover 3, A thimble 5 is provided between the spool 2 and the spring 4, one end of the thimble 5 is connected to the spring 4, and the other end is provided with a tapered tip 51. Correspondingly, the end surface of the spool 2 is provided with a shape corresponding to the tip 51. The recessed part 21 is adapted, and the recessed part 21 is a tapered hole, wherein the taper angle of the recessed part 21 is greater than the taper angle of the tip part 51 . The inside of the valve body 1 is provided with a raised step portion 11, and a guide hole 12 is opened on the step portion 11. The valve core 2 includes a guide...

Embodiment 2

[0030] A second embodiment of an end-face-sealed LNG filling port with a positioning structure of the present invention, such as Image 6 with Figure 7 As shown, the valve core 2 is provided with a raised sealing fit portion 22, wherein the sealing surface formed by the fit of the seal fit portion 22 and the stepped portion 11 is perpendicular to the axis of the valve body 1, that is, the valve body 1 and the valve core 2 The sealing method is axial end face sealing; further, the sealing fitting part 22 includes a sealing ring 25, and the sealing ring 25 is arranged on the surface of the sealing fitting part 22, and the sealing fitting part 22 is attached to the sealing surface of the stepped part 11 through the sealing ring 25 , the surface of the sealing ring 25 is a convex curved surface; the integrated design of the valve core 2 has a simple structure, reduces costs, and reduces cumulative tolerances. The thimble 5 is provided with a group of fluid channel holes 52, whic...

Embodiment 3

[0032] A third embodiment of an end-face-sealed LNG filling port with a positioning structure of the present invention, such as Figure 8 As shown, the spool 2 includes a guide shaft part 23, a concave base 30 and an annular seal 31, wherein the cross section of the concave base 30 is in the shape of a "concave", and forms a mounting groove for the annular seal 31 with the guide shaft part 23. The annular seal 31 is pressed into it, and other structures are the same as in Embodiment 1. In this way, the structure of the spool 2 is relatively simple, the assembly is easy, and the fixing of the annular seal 31 is more stable and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com