Thermal insulation double-stop discharge sampling valve

A technology of sampling valve and discharge port, which is applied in the field of thermal insulation double cut-off discharge sampling valve, to achieve the effect of stable water flow in the pipe, simple structure and increased frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

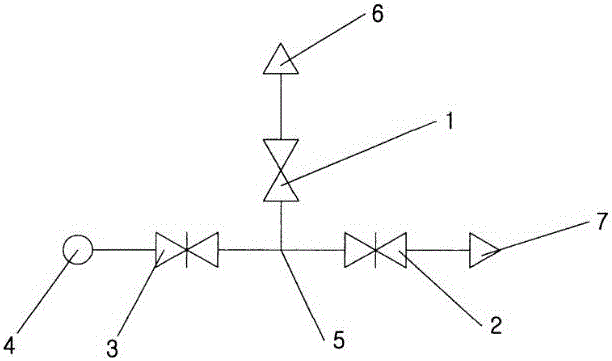

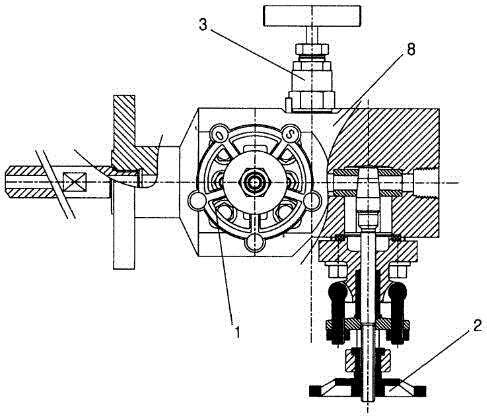

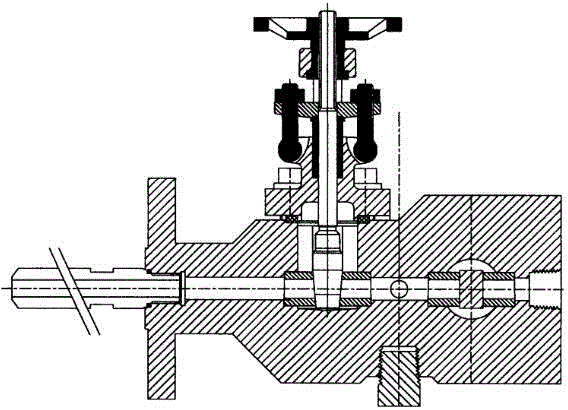

[0023] A thermal insulation double cut-off discharge sampling valve, such as figure 1 , figure 2 , image 3 As shown, it includes the main cut-off gate valve 1 and the valve body 8. The valve body 8 is provided with a valve body inlet 4. The valve body inlet 4 is connected to one end of the needle valve 3, and the other end of the needle valve 3 is connected to the T-shaped channel 5. The other two connecting ports of the T-shaped channel 5 are respectively connected with one end of the main cut-off gate valve 1 and the second cut-off gate valve 2; the other end of the main cut-off gate valve 1 is connected with the main discharge port 6; the other end of the second cut-off gate valve 2 Connected to outlet 7. In the actual implementation process of the patent, after the flow medium enters through the inlet 4 of the valve body, when sampling is not perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com