Tangent circle gas inlet furnace smoke mixing chamber and lignite boiler comprising same

A mixing chamber and furnace smoke technology, applied in the direction of drying gas arrangement, dryer, combustion method, etc., can solve the problems of metal wall cracking, coking of lignite boilers, etc. Crack, avoid direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

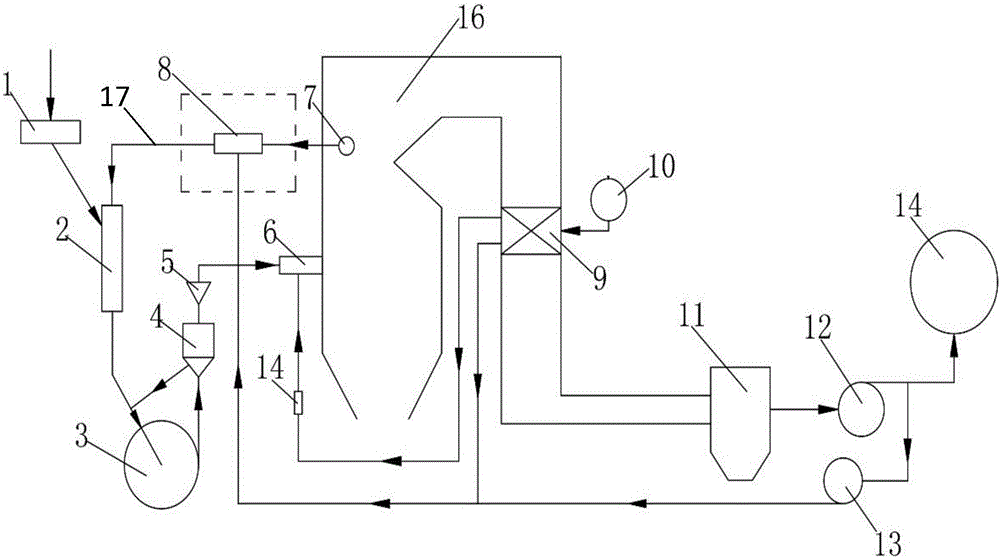

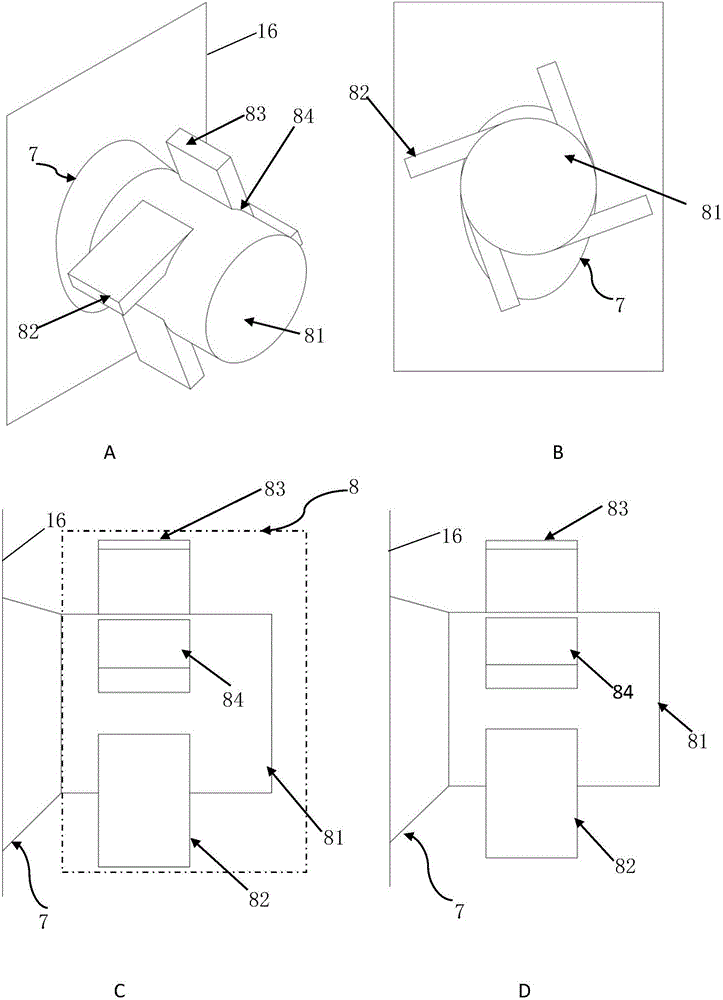

[0028] The specific implementation manners of the embodiments of the present invention will be described below in conjunction with the accompanying drawings.

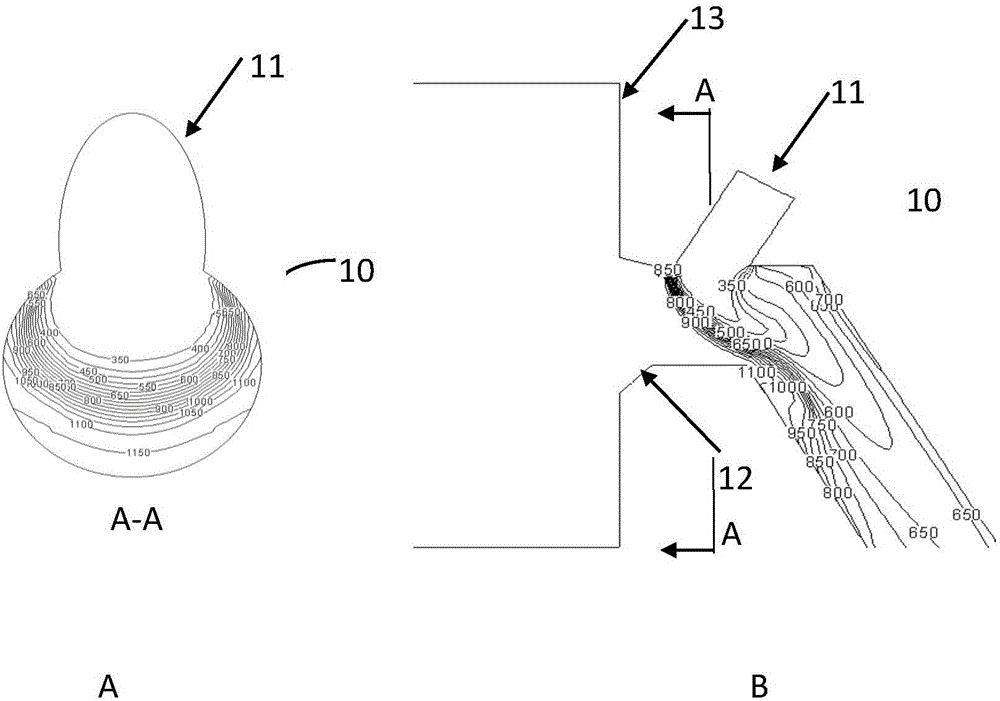

[0029] figure 2 It is a schematic structural diagram of a fan mill three-medium drying direct-blown pulverizing system in an embodiment of the present invention.

[0030] Such as figure 2 As shown, the fan mill three-medium drying direct blowing pulverizing system includes a coal feeder 1, a downward drying pipe 2, a fan coal mill 3, a coarse powder separator 4, a pulverized coal distributor 5, a burner 6, and a furnace exhaust port 7. Smoke mixing chamber of tangential inlet furnace 8, air preheater 9, air blower 10, dust collector 11, induced draft fan 12, cold smoke fan 13, secondary air box 14, chimney 15, lignite boiler 16. The lignite boiler 16 provided in this embodiment includes a furnace smoke outlet 7 and a furnace smoke mixing chamber 8 with a tangential air inlet.

[0031]In the fan mill three-medium dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com