Making method of three-dimensional atom probe sample

A technology of atom probe and sample, which is applied in the field of preparation of three-dimensional atom probe samples, can solve the problems of easy breakage of samples, Pt desoldering, etc., and achieve the effects of high repeatability, improved accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with preferred embodiments.

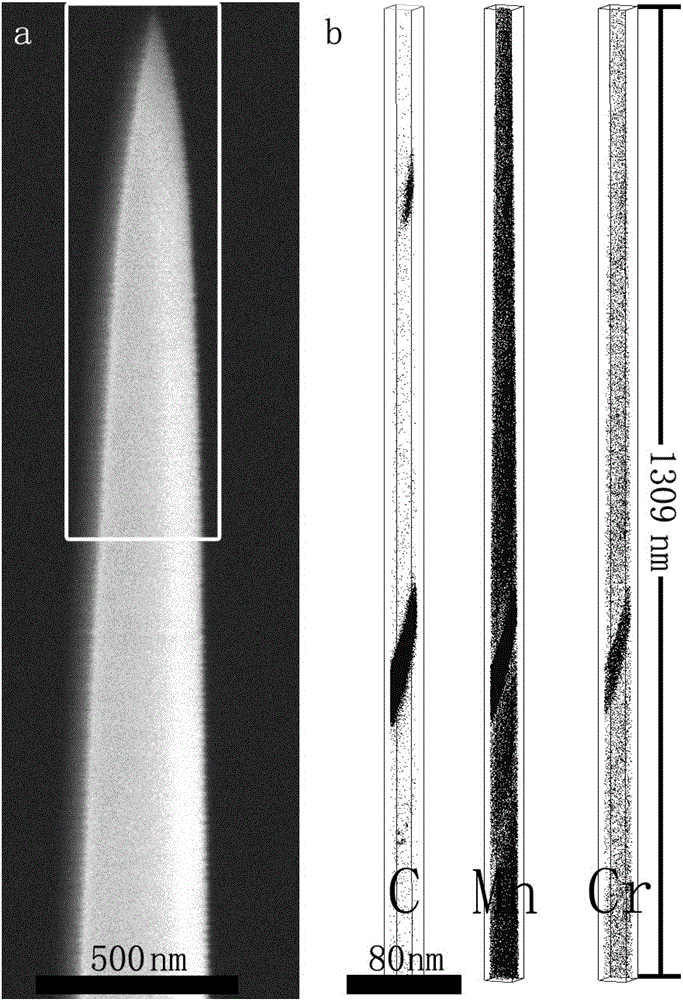

[0021] The region of interest in this embodiment comes from the vicinity of a steel sample crack;

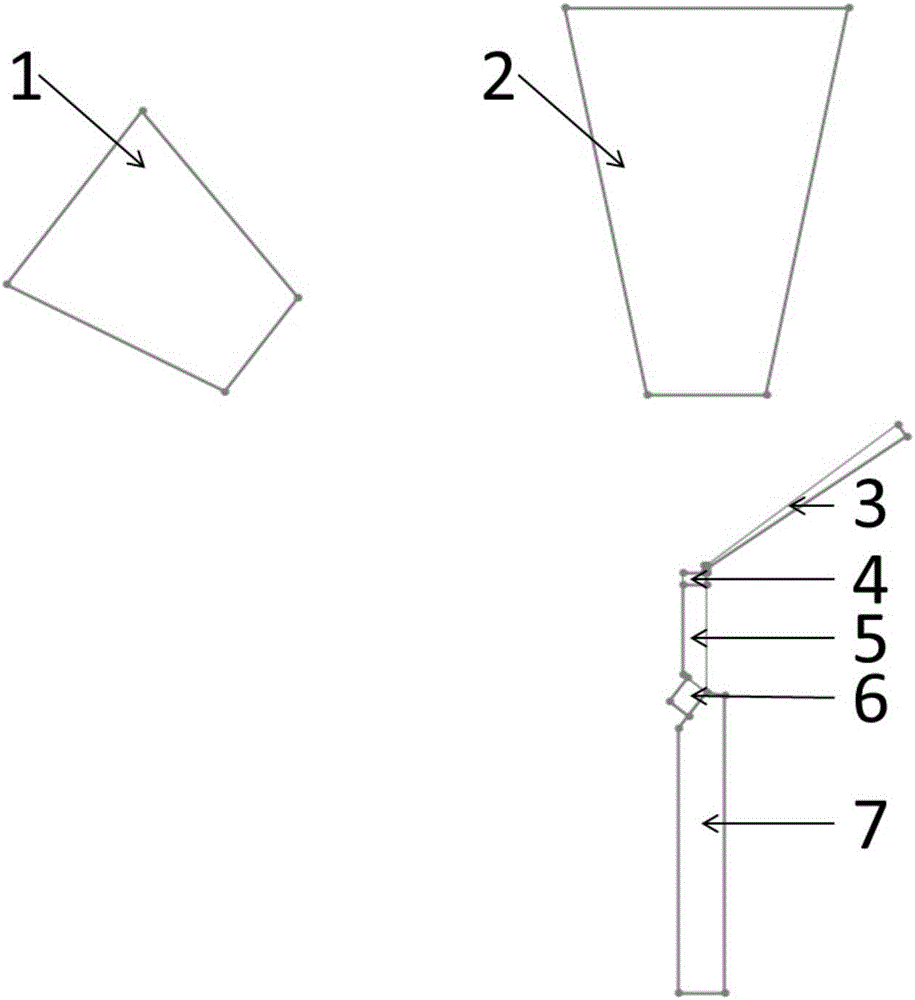

[0022] (1) Spray the Pt protective layer 4 on the area of interest, and use the focused ion beam to cooperate with the manipulator 3 to extract the area of interest 5. The specific steps are as follows:

[0023] 1) The sample stage is tilted at 52 degrees, and the area of interest is selected with electron beam 2, and Pt is sprayed on the area of interest with ion beam 1: a Pt layer of 4 μm in length × 2 μm in width × 2 μm in thickness, and then the area of interest is concaved up and down with the ion beam pit;

[0024] 2) Turn the sample stage to 0 degrees, use the ion beam to cut off the right side and bottom side of the sample, cut off the bottom left side, leave the upper left cantilever, weld Pt on the top of the manipulator and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com