An array substrate, a method for manufacturing the array substrate and a display device

A technology of an array substrate and a manufacturing method, which is applied in the field of display devices, can solve problems such as reducing the brightness of a display panel, and achieve the effects of reducing energy consumption and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

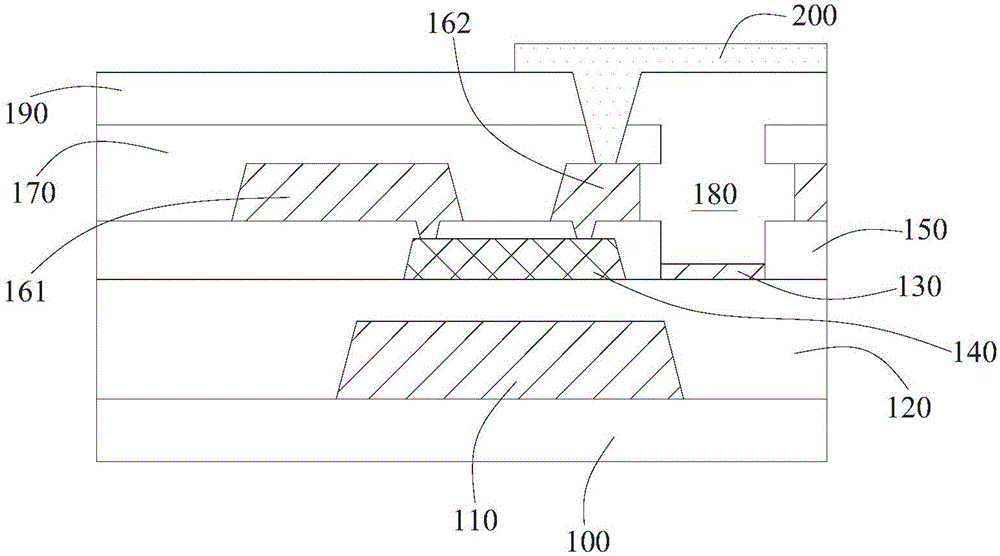

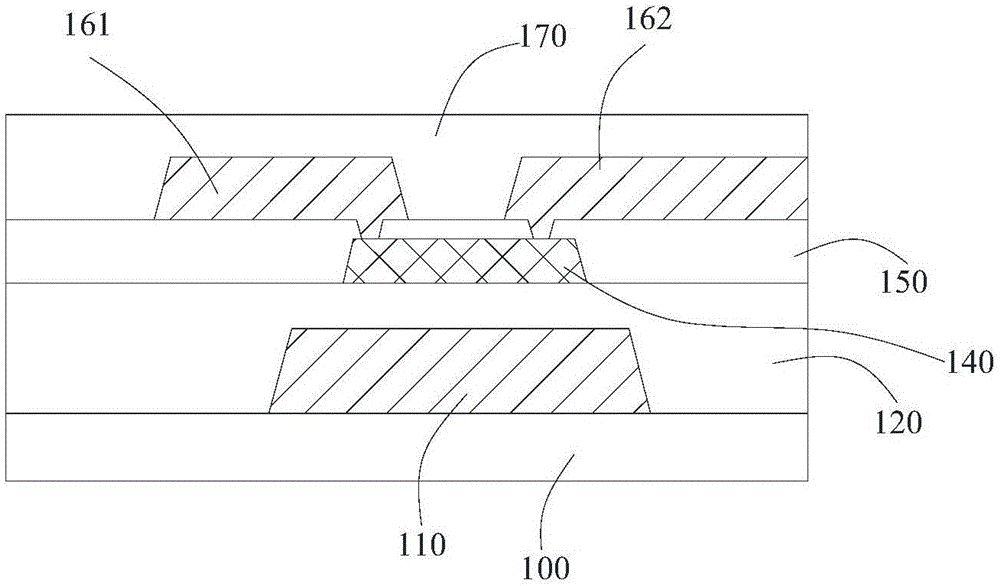

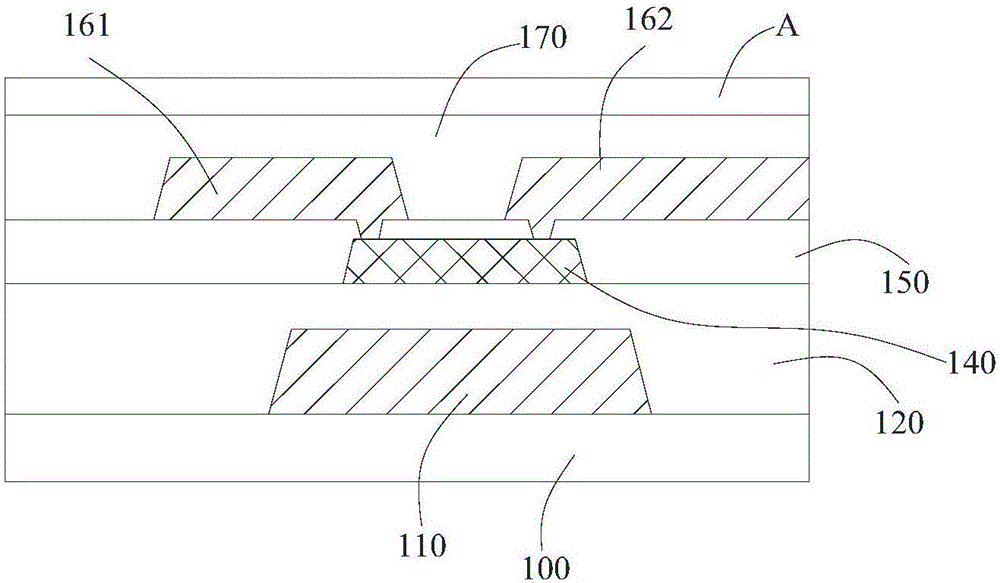

[0070] As a preferred implementation manner, the active layer 140 of the thin film transistor is made of oxide, and the transparent filter layer 150 is located between the active layer 140 of the thin film transistor and the layer where the source electrode 161 is located. As shown in the figure, the source electrode 161 and the drain electrode are respectively connected to the active layer 140 through via holes penetrating through the transparent filter layer 150 . In the present invention, the transparent filter layer 150 can also be used as an etch stop layer to prevent damage to the active layer 140 during the steps of forming the source and drain electrodes. As a preferred embodiment of the present invention, the active layer 140 can be made of IGZO.

[0071] In the present invention, the specific material of the transparent filter layer 150 is not particularly limited, as long as it can allow light to pass through. As a preferred embodiment of the present invention, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com