Horizontal position accurate positioning control method of coil conveying trolley with encoder

A rolling trolley and precise positioning technology, applied in two-dimensional position/channel control, vehicle position/route/height control, non-electric variable control, etc., can solve problems such as unfavorable production and complex equipment, and achieve improved stability , to meet the effect of on-site transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

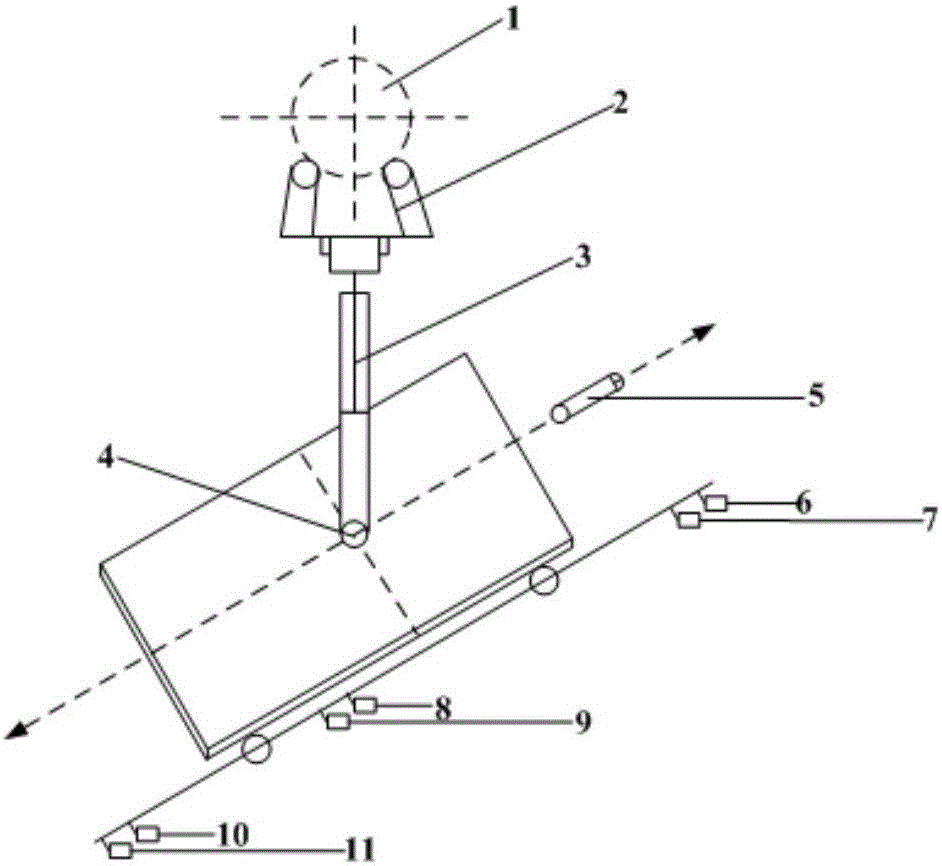

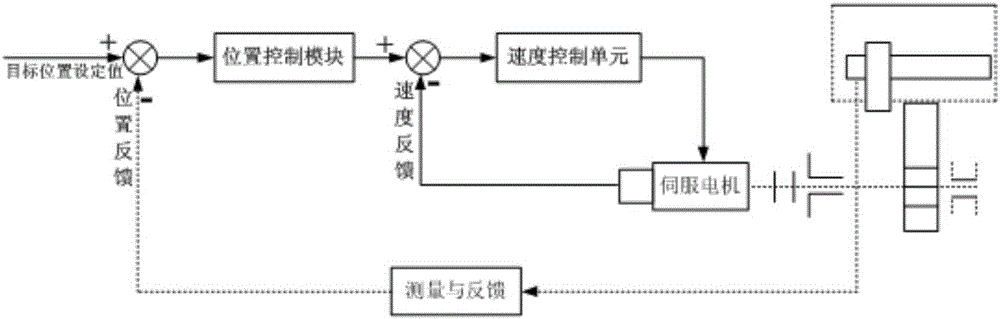

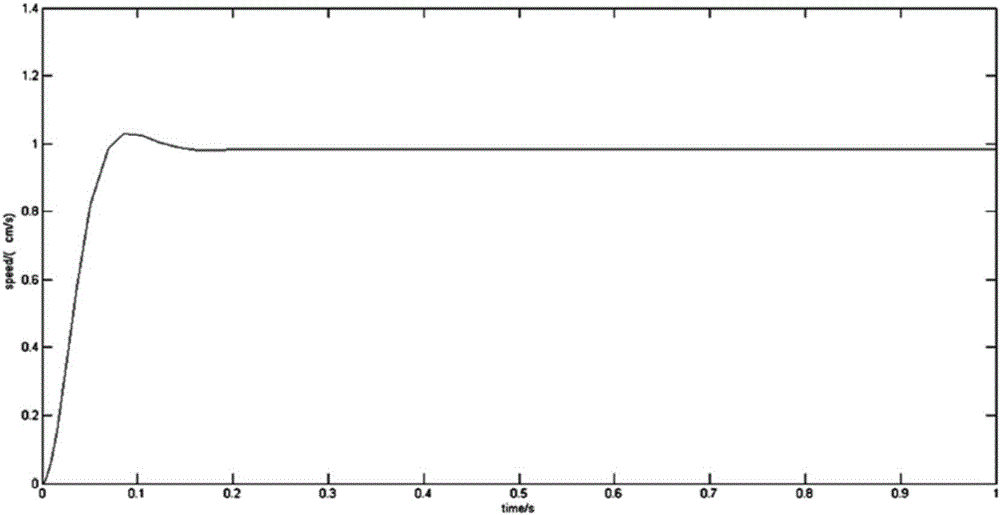

[0032] A method for accurately positioning and controlling the horizontal position of a rolling trolley with an encoder. The method is used to realize the smooth control of the running and starting and stopping of the rolling trolley. The wheels of the rolling trolley are installed to detect the actual displacement of the rolling trolley. Value of the rotary encoder, the rotary encoder is a rotary encoder with absolute value encoding, the current value of the actual displacement of the rolling trolley is transmitted to the programmable controller (PLC), the programmable controller is set There is a PI controller, the programmable controller generates a ramp signal, the ramp signal is input to the PI controller (ie proportional integral controller), the PI controller calculates the output signal according to the ramp signal and The output signal is sent to the speed actuator of the rolling trolley via the field bus to realize the closed-loop control of the position of the rolling...

Embodiment 2

[0097] A method for precise positioning and control of the horizontal position of the rolling trolley with encoder. The wheels of the rolling trolley are equipped with a rotary encoder with absolute value encoding, which can detect the horizontal position of the trolley, and the acceleration and deceleration of the rolling trolley are controlled by a reduction motor , The built-in brake of the geared motor is used for parking of the trolley. The control of the rolling trolley is a double closed loop system, the inner loop is a speed loop, and the outer loop is a position loop. The position loop calculates the required speed value according to the position deviation, and sends the speed command to the speed control unit. The speed control unit outputs the signal to the servo motor, and controls the speed of the rolling trolley by controlling the servo motor. In the acceleration and deceleration process, the PI controller is put into the position loop, the input of the PI control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com