Contact supporting assembly of direct-current contactor

A DC contactor and contact support technology, which is applied in the direction of relays, electrical components, electromagnetic relays, etc., can solve the problems that cannot meet the performance requirements of charging piles, improve contact support components, and complex processes, and achieve simplified pre-charging circuits. , reduce material costs, simplify the effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

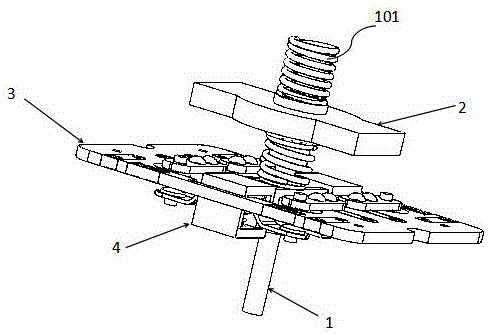

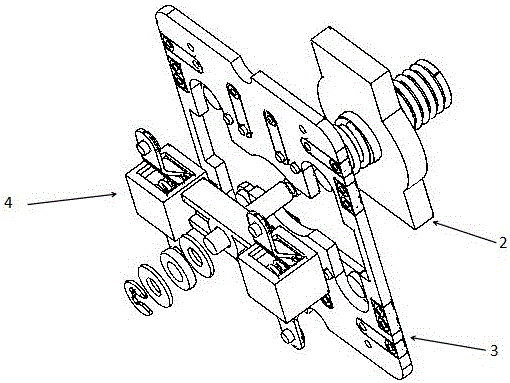

[0028] like figure 1 and 2 As shown, a contact support assembly of a DC contactor includes a push rod 1, a movable contact bridge assembly 2, a mounting plate assembly 3 and a support assembly 4; Made of magnetically conductive metal, the upper end of the push rod 1 is provided with a compression spring 101, and the compression spring 101 is placed on the open retaining ring and flat pad of the first slot of the push rod 1, and the compression spring 101 is pressed against the first position of the push rod 1. The opening retaining ring of a card slot is between the flat pad and the top end of the push rod 1 .

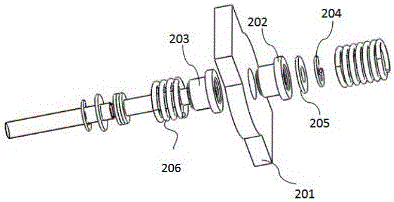

[0029] like image 3 As shown, the moving contact bridge assembly 2 includes an active contact 201, a spring seat and a contact spring 206, the active contact 201 is arranged between the first spring seat 202 and the second spring seat 203, and the active contact 201 passes through the first spring The seat 202 and the second spring seat 203 are sleeved into the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com