Battery charge method

A battery charging and battery technology, applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problems of reducing battery life, battery material failure, etc., to reduce battery life, improve cycle life, improve The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

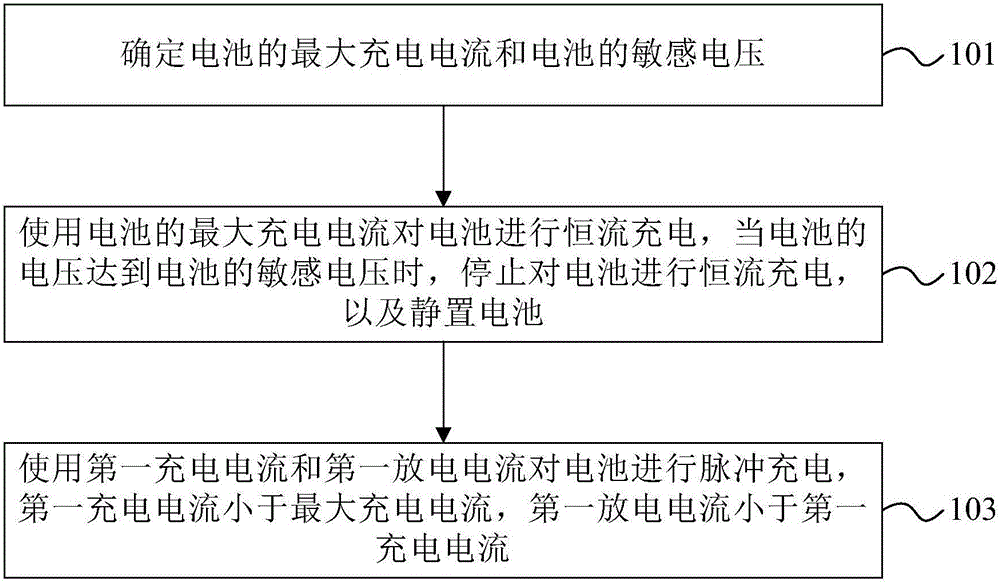

[0037] figure 1 A schematic flow chart of the battery charging method provided by the embodiment of the present invention, such as figure 1 As shown, the battery charging method of this embodiment may specifically include the following steps:

[0038] 101. Determine the maximum charging current of the battery and the sensitive voltage of the battery.

[0039] In the embodiment of the present invention, different positive electrode materials and negative electrode materials are used to make battery cells. Due to the different properties of the battery cell materials themselves, the performance of the battery is jointly determined. Therefore, before charging the battery, it is first necessary to confirm the maximum charging current of the battery and the sensitive voltage of the battery.

[0040] In the embodiment of the present invention, the maximum charging current of the battery refers to the maximum current that the positive electrode material in the cell of the battery c...

Embodiment 2

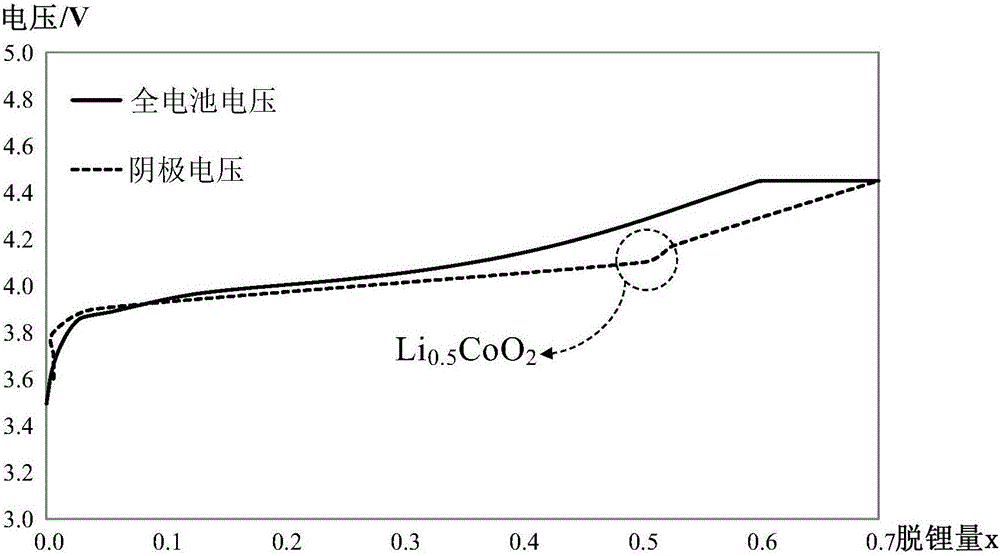

[0061] In this embodiment, three sets of experiments will be used for comparative analysis, and the three sets of experiments will use different methods to charge batteries of the same specification, and three sets of different experimental results will be obtained. Among them, the battery cell uses LiCoO 2 As the cathode material and graphite as the anode material, two batteries were used for each experiment. Specifically, the cathode is made of 96.7% LiCoO 2 +1.7%PVDF+1.6%SP mixed composition, the anode is composed of 98% artificial graphite+1.0%SBR+1.0%CMC, the electrolyte is composed of organic solvent (30%EC+30%PC+40%DEC) and 1mol / L LiPF 6 , and then add additives (0.5% VC, 5% FEC, 4% VEC) composition.

[0062] The first set of experiments:

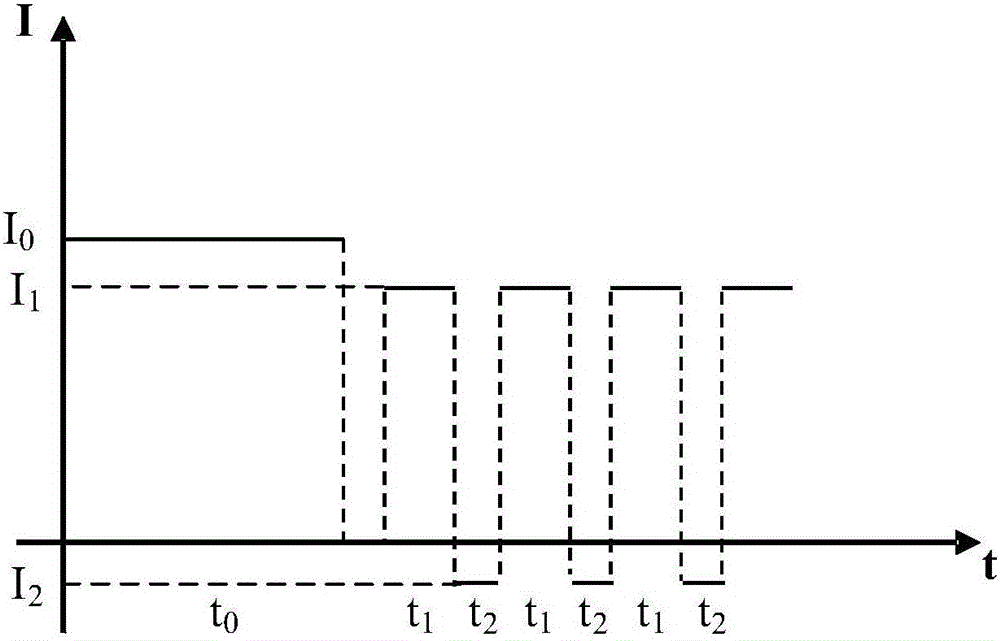

[0063] Figure 4 It is an example diagram of the relationship between time and current in the battery charging method in the prior art. Such as Figure 4 As shown, the battery is charged using the battery charging method in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com