Built-in water-blocking pin in middle connection part of all-insulated pipe bus

A fully insulated pipe busbar and water-blocking technology, which is applied in the direction of fully enclosed busbar device, busbar installation, electrical components, etc., can solve the problems of dry-type fully insulated pipe busbar being unsuitable, losing waterproof effect, and insulation being damp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

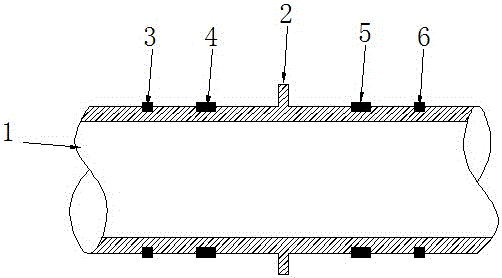

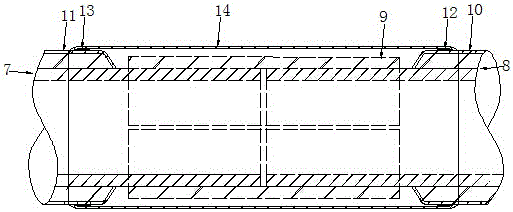

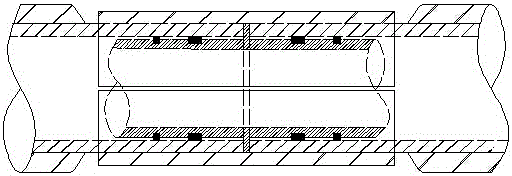

[0018] Below by example, in conjunction with accompanying drawing, the structure of the present invention is further described: as figure 1 The middle connection of the fully insulated pipe busbar shown in the figure has a built-in water blocking pin, including the water blocking pin body 1, the boss 2, the sealing waterproof layer 3, 6, and the water blocking layer 4, 5; the water blocking pin body 1 is used as the sealing waterproof layer 3 , 6, and the support body of the water blocking layer 4, 5 are hollow cylinders, made of non-magnetic metal or plastic, with a length of 50 mm to 200 mm, and an outer diameter smaller than the inner diameter of the conductor tube connected to the fully insulated busbar by 1 mm. ~5mm. The boss 2 is placed in the longitudinal center of the outer surface of the water blocking pin body 1, mainly to prevent the water blocking pin as a whole from moving in the conductor tube and sliding into one side of the conductor tube, resulting in failure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com