Servo motor for robot

A technology of servo motor and robot, applied in the field of servo motor, can solve the problem of short service life of encoder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

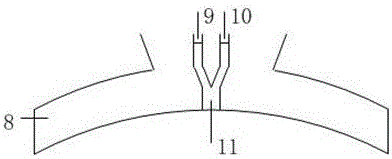

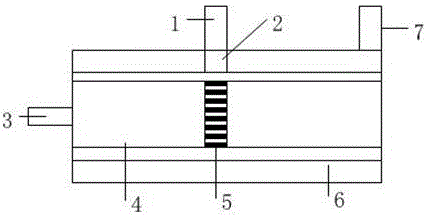

[0010] Such as figure 1 , figure 2 As shown, the structure of the present invention includes a motor, a signal receiver 7, a signal transmitter 1, the motor includes a stator 6, a rotor, the stator 6 includes a tooth portion 8, a yoke, and the rotor includes a rotor core 4, a rotating shaft 3; It is characterized in that: the signal transmitter 1 is connected to the photoelectric counter 2, and the photoelectric counter 2 is a coaxial reflective photoelectric counter, and its light-emitting element 9, photosensitive element 10, and optical fiber 11 are all located in one of the stator 6 On the tooth portion 8, the tooth portion has a through hole for the light emitting element 9, the photosensitive element 10, and the optical fiber 11 to pass through, and the outer wall of the rotor core 4 of the rotor is vertically opposite to the light emitting element 9 and the photosensitive element 10. The counting ring 5 is embedded in a week, and the counting ring 5 has a corrugated e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com