Preparation method and application of zinc lysine feed additive with moderate chelation strength

A feed additive, zinc lysine technology, applied in animal feed, application, additional food elements, etc., can solve problems that have not been reported, reduce environmental pollution, reduce blind production and inefficient addition of organic zinc, and improve production benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Prepare medium chelating strength lysine zinc chelate with feed grade L-lysine sulfate (L-lysine effective content 55%) and feed grade zinc sulfate (measured zinc content 33.44%).

[0016] Weigh 296.81g of feed grade L-lysine sulfate (about 1.11 moles of L-lysine), dissolve it in a beaker with ultrapure water, heat to 60°C under stirring, and keep the temperature constant. After the L-lysine sulfate is completely dissolved, add 109.91g of feed grade zinc sulfate (approximately 0.55 moles of zinc), adjust the pH value of the reaction solution to 9.0 with 40% sodium hydroxide solution, and react for 30min. Concentrate the reaction solution with hot air in the oven until the crystal film appears, take it out from the oven and cool it at room temperature, and a large amount of precipitates precipitate out. Centrifuge at 4000r / min for 20min, discard the supernatant, wash the precipitate three times with 95% ethanol, dry at 75°C, crush and pass through a 40-mesh...

Embodiment 2

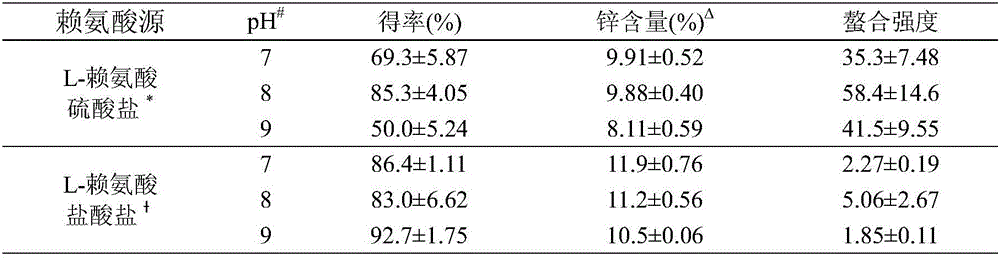

[0017] Embodiment 2: with feed grade L-lysine sulfate (L-lysine effective content 55%), feed grade L-lysine hydrochloride (L-lysine effective content 78.8%) respectively with feed Grade zinc sulfate (measured zinc content 33.44%) has a chelation reaction, and compares the difference in chelation strength of zinc lysine samples prepared from two lysine raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com