A high-precision tensioning device

A tensioning device, high-precision technology, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problem of wheel hub tilt, machining size out of tolerance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The details and working conditions of the device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

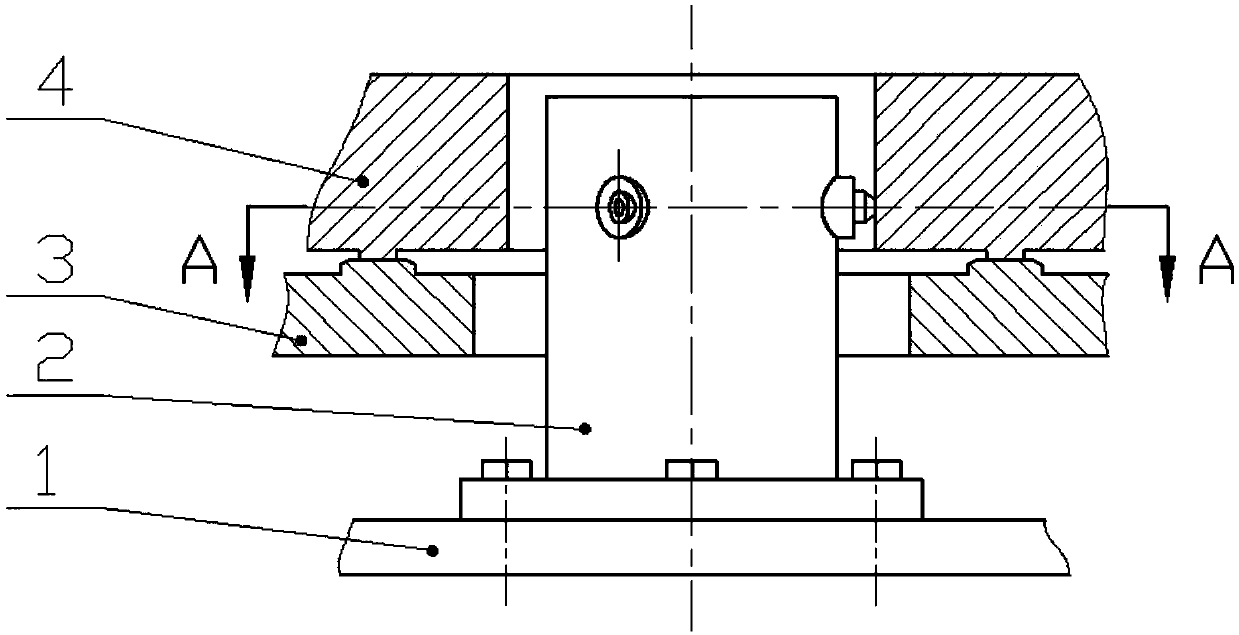

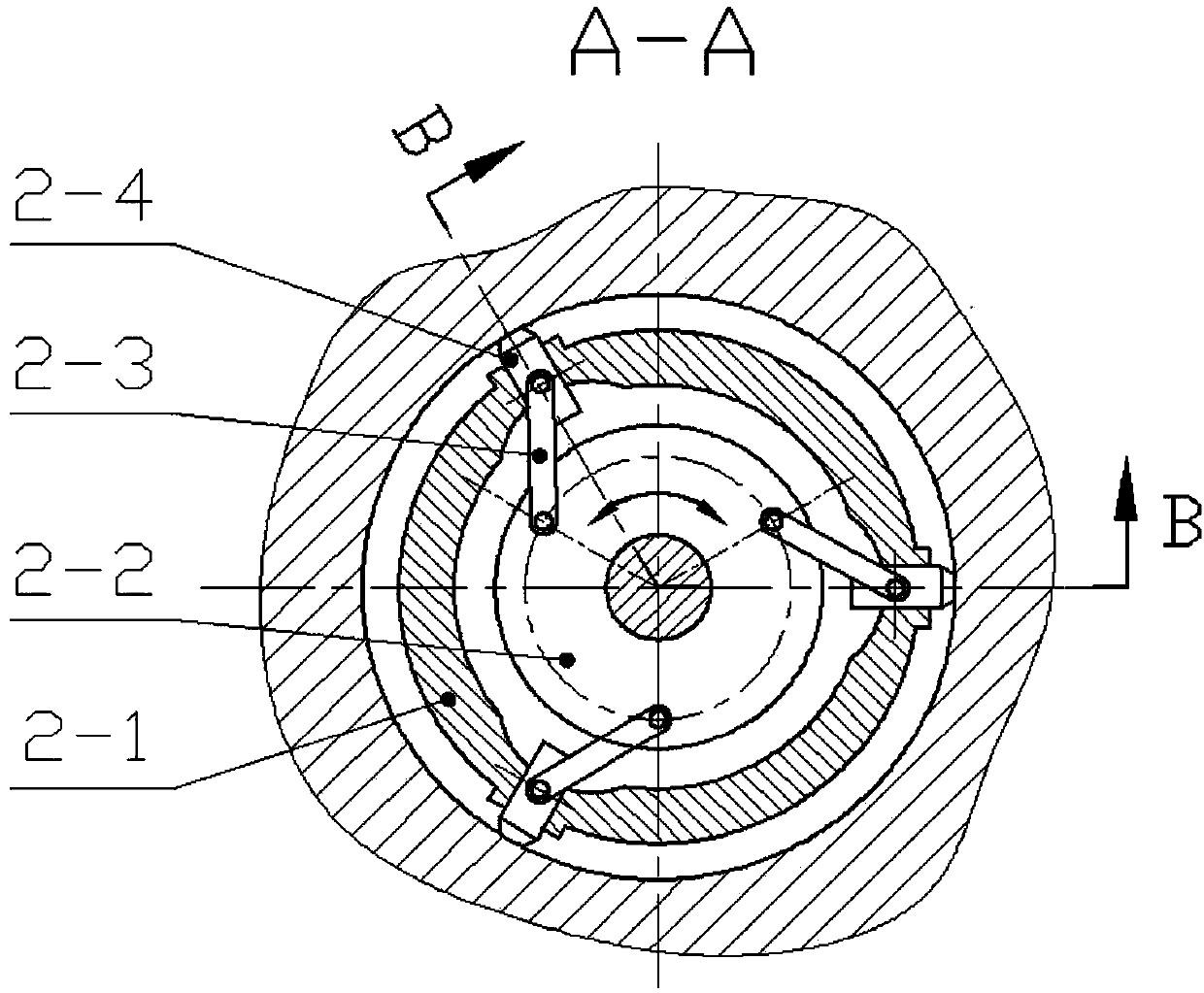

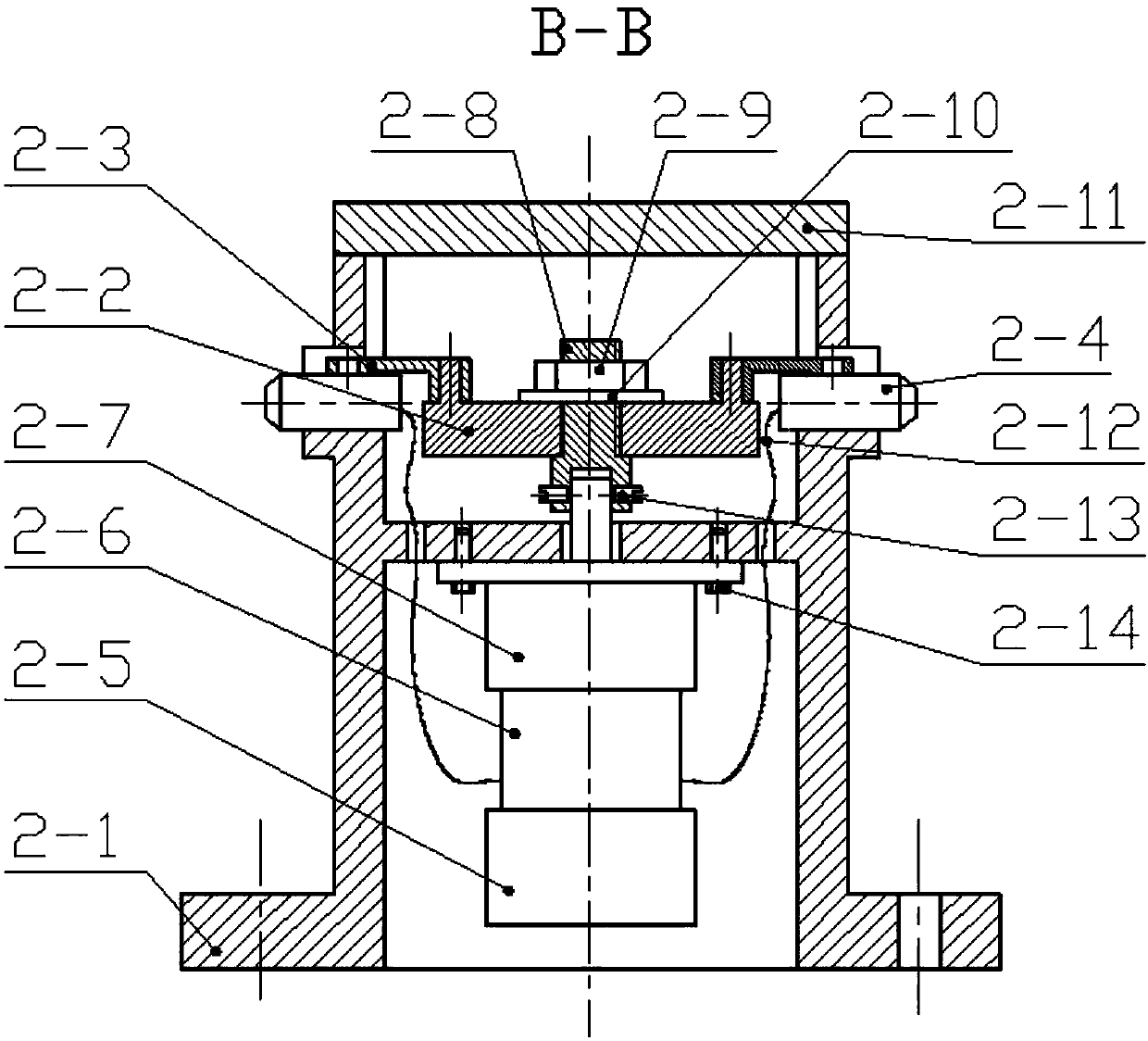

[0020] This embodiment proposes a new type of tensioning mechanism, which is installed as figure 1 As shown, the high-precision tensioning device 2 of the present invention passes through the inner holes of the hub processing base 3 and the hub 4 and is fixed on the base 1 . Mainly consists of stepping motor 2-6, encoder 2-5, harmonic reducer 2-7, turntable 2-2, connecting rod 2-3, contact 2-4, force sensor 2-12, turntable connector 2 -8, gasket 2-10, nut 2-9, bolt 2-14, set screw 2-13, shell 2-1 and end cover 2-11. The back end of the stepping motor 2-6 is connected to the encoder 2-5, and the output end is connected to the harmonic reducer 2-7, and the harmonic reducer 2-7 is fixed to the internal structure of the shell 2-1 by bolts 2-14 On, its output shaft is then connected with the turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com