Method for recovering diamond by gas-liquid-solid phase method

A diamond and solid phase method technology, applied in the field of waste recycling and environmental protection, can solve the problems of polluted water, environmental pollution, a large amount of evaporative condensation wastewater, etc., and achieve the effect of no wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

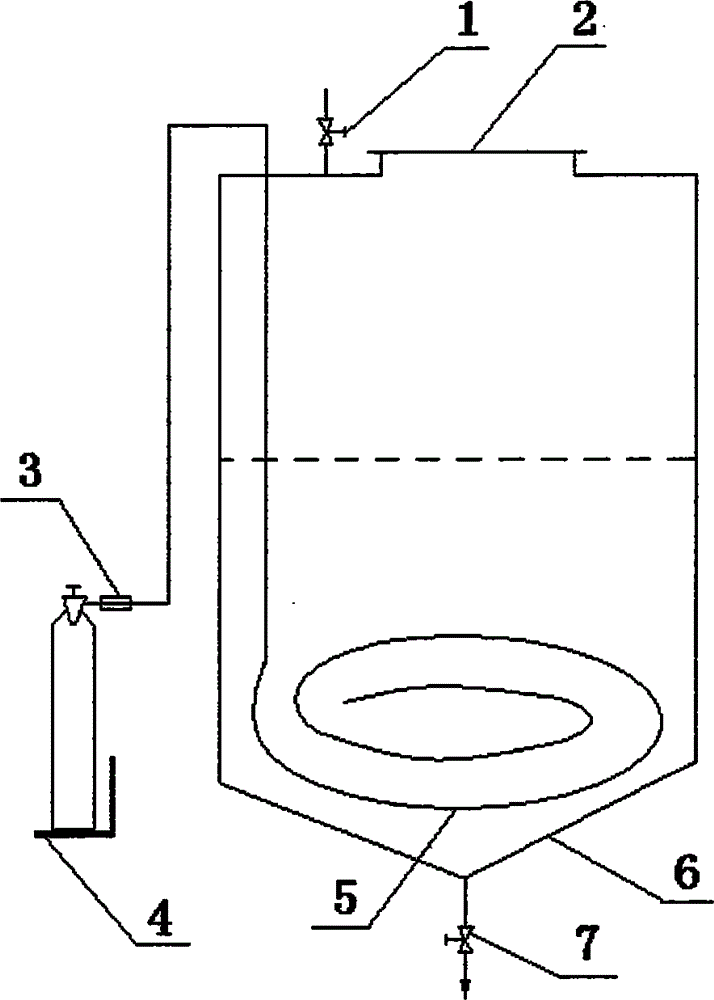

[0018] Such as figure 1 As shown, the gas-liquid-solid phase reaction device is composed of a reaction kettle 6, a kettle cover with a sealing gasket and a chlorine gas distributor 5 and the like. The reaction kettle 6 is made of acid-resistant and heat-resistant plastic, and the bottom of the kettle is made into a conical shape. The drain pipe with the drain valve 7 is installed at the lowest point of the bottom of the kettle. Pipe, side top is provided with one end and links to each other with chlorine valve 3, and the other end inserts the inlet pipe that links to each other with chlorine distributor 5 at the bottom of the kettle.

[0019] When implementing the present invention, add water in the reactor 6 of gas-liquid-solid phase reaction device, water yield is equal to 2 / 5 of reactor 6 volumes; Be equal to the ratio of 1 / 5 by the weight ratio of diamond waste product and water, add diamond waste product Pad sealing ring, lid reactor 6 lid 2; Open chlorine valve 3, feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com