A kind of processing technology of removing copper slag from crude tin

A treatment process, crude tin technology, applied in the field of copper slag removal process of crude tin, can solve the problems of easy sticking to the kiln wall, low melting point of tin, etc., and achieve the effect of low cost, high yield and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

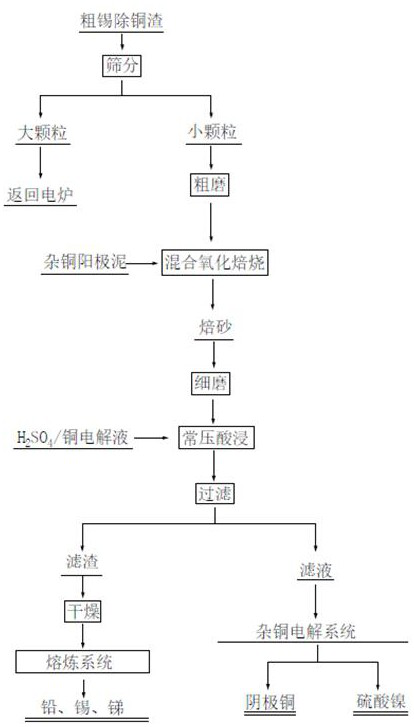

[0026] Example: according to figure 1 Operate as shown.

[0027] A typical chemical composition of coarse tin copper removal slag is shown in Table 1:

[0028] Table 1 Chemical composition of a typical crude tin copper removal slag, unit: %

[0029] Cu Ni Fe sn Pb Sb S 27.65 1.13 0.44 33.8 26.68 1.49 12.85

[0030] 1. Sieve the coarse tin decopper slag with a 20-mesh stainless steel mesh sieve to obtain the undersieve and the oversieve. -80 mesh accounts for more than 95% to obtain coarse tin and copper slag powder.

[0031] 2. Mix the crude tin decopper slag powder and miscellaneous copper anode slime with a water content of 0.5% in a mixer or with a forklift, and use a belt scale to send it to the rotary kiln for oxidation and roasting operations. The crude tin decopper slag and The weight ratio of mixed copper anode slime is 1:0.5, the feed rate is 2t / h, the inlet temperature of the rotary kiln is 200-210°C, the temperature of the kiln...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com