High-barrier nano organic montmorillonite-polyethylene glycol terephthalate composite material and method for preparing same

A polyethylene terephthalate, nano-organic technology, which is applied in the field of high-barrier nano-organic montmorillonite-polyethylene terephthalate composite material and its preparation field, can solve the problem of nano-organic montmorillonite The orientation cannot be regulated, it is difficult to realize industrialized production, and the process route is complex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

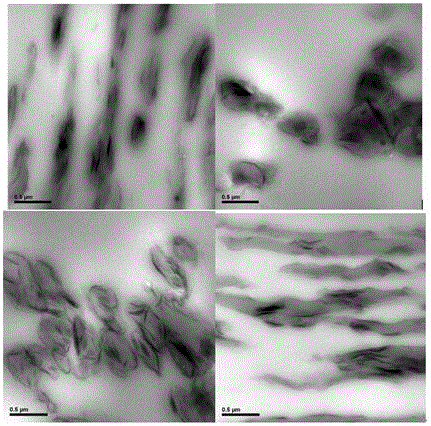

Image

Examples

Embodiment 1

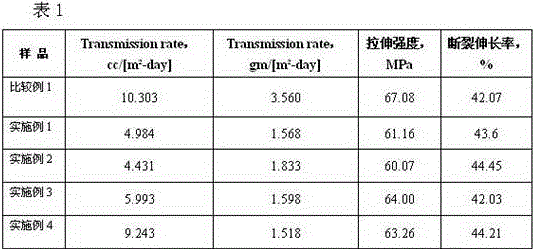

[0018] Embodiment 1 of the present invention: high-barrier nano-organic montmorillonite-polyethylene terephthalate composite material, calculated in parts by mass, including 100 parts of polyethylene terephthalate matrix resin and layers 2 parts of nano-organic montmorillonite; the polyethylene terephthalate has an intrinsic viscosity of 0.75-0.85 dl / g and a density of 1.4±0.01 g / cm 3 .

[0019] The preparation method of high-barrier nano-organic montmorillonite-polyethylene terephthalate composite material comprises the steps of:

[0020] 1) Dry polyethylene terephthalate in a drying tank at 120°C for 1 hour, then increase the temperature of the drying tank to 150°C, and dry for 5 hours; Drying for 24 hours to obtain dry raw material components;

[0021] 2) Premix the dried raw material components obtained in step 1) to obtain a premix;

[0022] 3) Put the premix obtained in step 2) into a co-rotating parallel twin-screw extruder for melt blending and extrusion, and the me...

Embodiment 2

[0023] Embodiment 2 of the present invention: high-barrier nano-organic montmorillonite-polyethylene terephthalate composite material, calculated in parts by mass, including 100 parts of polyethylene terephthalate matrix resin, ply 2 parts of nano-organic montmorillonite and 8 parts of compatibilizer; the polyethylene terephthalate has an intrinsic viscosity of 0.75-0.85 dl / g and a density of 1.4±0.01 g / cm 3 ; The compatibilizer is maleic anhydride grafted polyethylene.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0025] Embodiment 3 of the present invention: high-barrier nano-organic montmorillonite-polyethylene terephthalate composite material, calculated in parts by mass, including 100 parts of polyethylene terephthalate matrix resin, ply 2 parts of nano-organic montmorillonite and 8 parts of compatibilizer; the polyethylene terephthalate has an intrinsic viscosity of 0.75-0.85 dl / g and a density of 1.4±0.01 g / cm 3 ; The compatibilizer is ethylene-methacrylic acid-acrylate terpolymer.

[0026] The preparation method was the same as in Example 1, wherein the ethylene-methacrylic acid-acrylate terpolymer was first dried in an oven at 50° C. for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com