Oxygen Feed Control System and Its Gasifier Feed System

A feed control, oxygen technology, applied in granular/powder fuel gasification, gasification process, gasification device details, etc., can solve the problems of complex structure, high operation intensity, high investment cost, etc., to reduce hardware investment , the effect of enhancing reliability and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

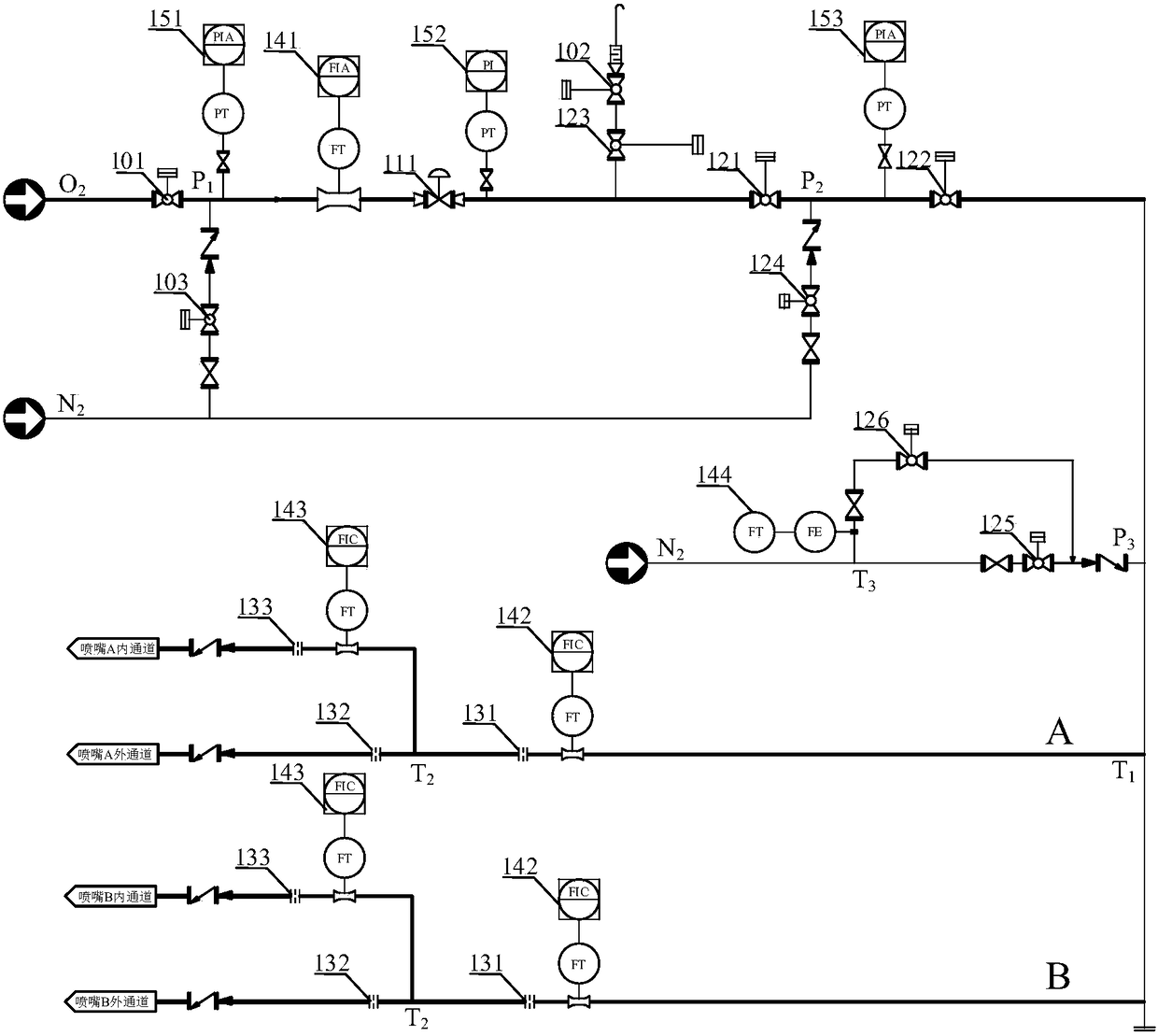

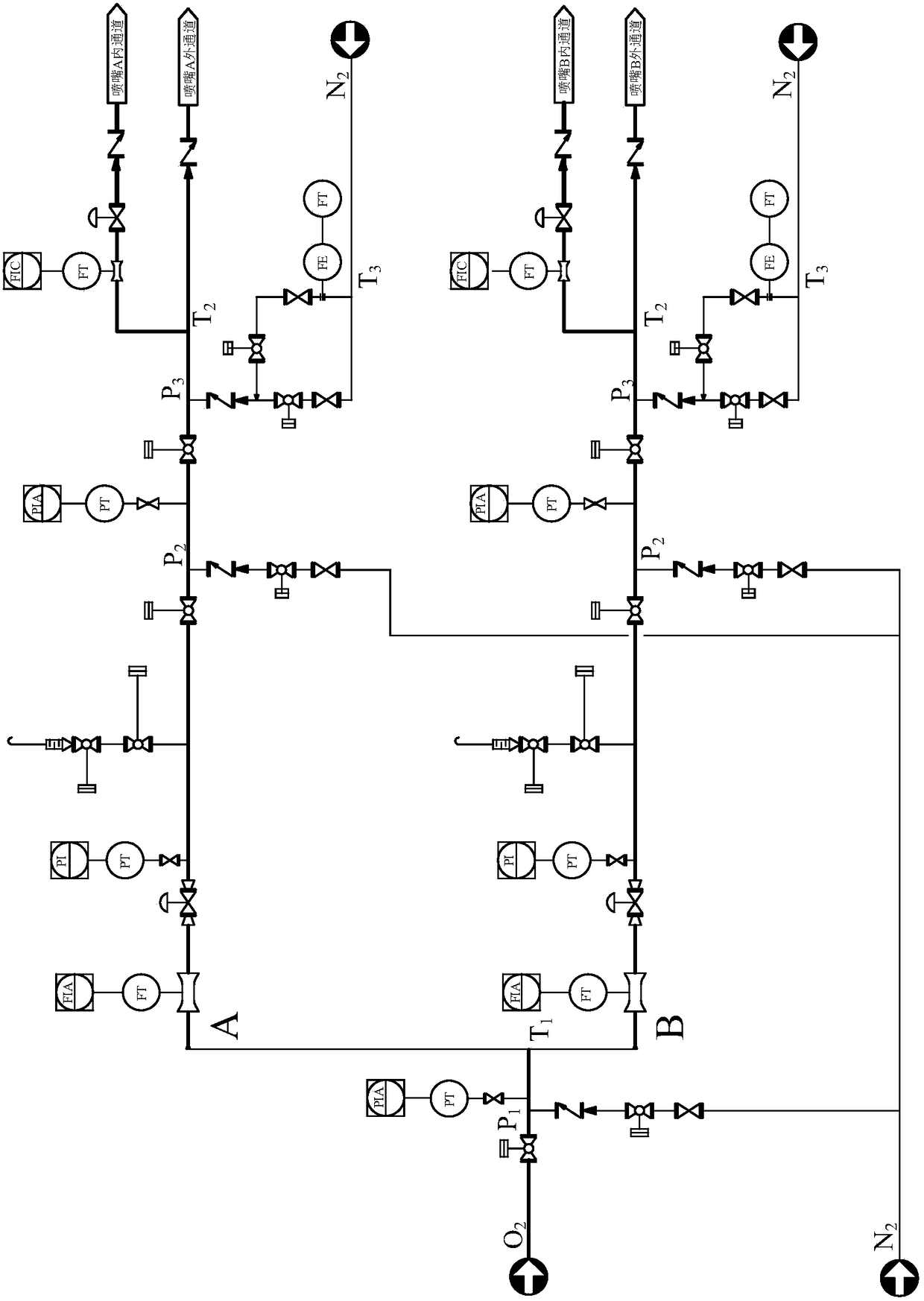

[0039] a kind of like figure 1As shown in the oxygen feed control system, the oxygen feed control system includes an oxygen flow establishing system and an oxygen feeding system; the pipeline of the oxygen flow establishing system passes through the first remote control valve 101 and the oxygen flow regulating valve sequentially from the oxygen source 111 is connected with the oxygen feeding system; the pipeline of the oxygen feeding system is divided into branch pipe A and branch pipe B after the first shut-off valve 121 and the second shut-off valve 122 in turn, and each branch pipe passes through the branch pipe throttling element 131 and Nozzle connection. The pipeline between the oxygen flow regulating valve 111 and the first shut-off valve 121 is also provided with a venting branch pipe, and the pipeline of the venting branch pipe is connected to the atmosphere through the third shut-off valve 123 and the second remote control valve 102 to vent in sequence. Each of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com