Low-grade vanadium titano-magnetite oxidized pellet expansion restraining and upgrading process for gas-based shaft furnace

A technology of vanadium-titanium magnetite and oxidation pellets, which is applied in the field of metallurgy, can solve the problems of increasing the cost of oxidation and roasting, and achieve the effect of improving reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

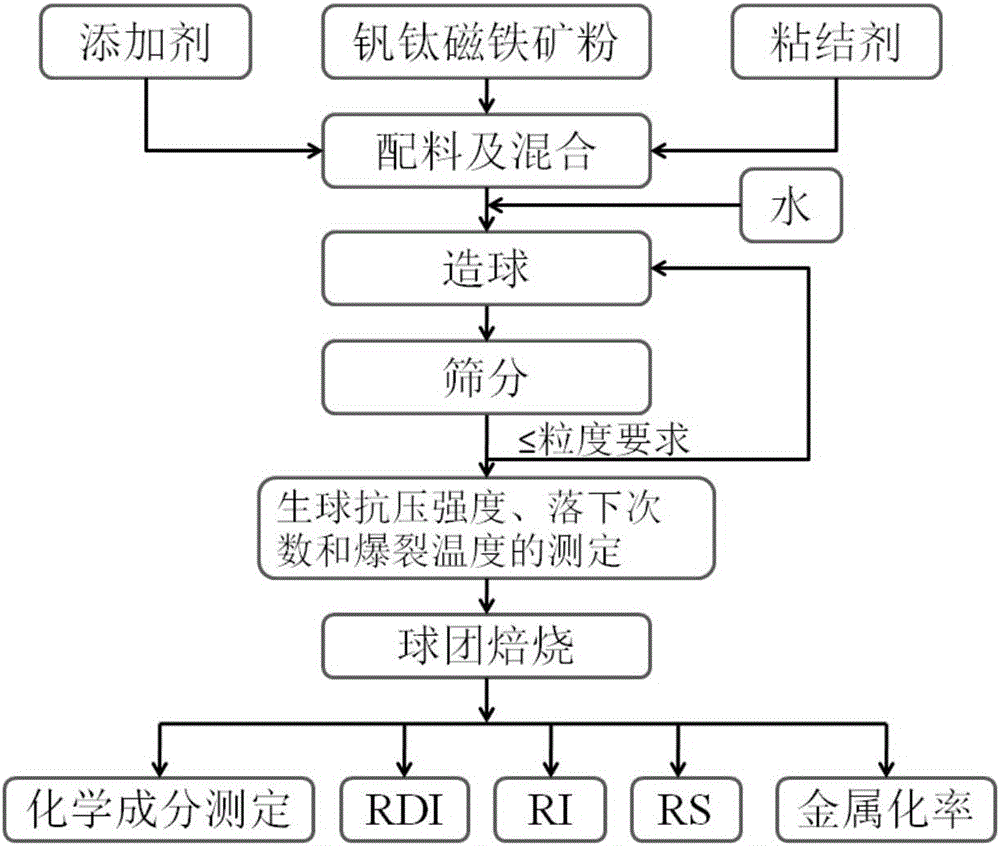

Method used

Image

Examples

Embodiment 1

[0038] Get 5kg vanadium-containing titanium magnetite, wherein 59wt% TFe, 13wt% TiO 2 , 11wt% (CaO+MgO+SiO 2+Al 2 o 3 ), the particle size below 0.074mm accounts for more than 80%. Based on vanadium-titanium-magnetite, 30g of composite binder and 50g of additives are added externally according to mass percentage, stirred on a mixer for 6 minutes, and then 5% water is added externally, and stirred for 10 minutes. Pellet the mixture in a disc pelletizer, sieve, put 10-12mm green balls into a roasting cup, and use liquefied petroleum gas to oxidize and roast according to the following roasting system: drying starts at room temperature, and heats up to 350°C. Constant temperature for 8 minutes, air volume 35m 3 / h; then heat up to 900°C, keep the temperature constant for 15 minutes, and air volume 15m 3 / h; continue to heat up to 1200°C, keep the temperature constant for 25 minutes, and the air volume is 15m 3 / h; soaking section temperature 1150°C, time 5min, air volume 15m...

Embodiment 2

[0040] Get 5kg vanadium-containing titanium magnetite, wherein 50wt% TFe, 9wt% TiO 2 , 11wt% (CaO+MgO+SiO 2 +Al 2 o 3 ), the particle size below 0.074mm accounts for more than 65%. Based on vanadium-titanium-magnetite, 30g of composite binder and 50g of additives are added externally according to mass percentage, stirred on a mixer for 6 minutes, and then 6% water is added externally, and stirred for 10 minutes. Ball the mixture in a disc pelletizer, sieve, put 10-12mm green balls into a roasting cup, use liquefied petroleum gas to oxidize and roast according to the following roasting system: drying starts from room temperature, heats up to 300 °C, and keeps the temperature constant 10min, air volume 35m 3 / h; then heat up to 950°C, keep the temperature constant for 10 minutes, and air volume 15m 3 / h; continue to heat up to 1250°C, keep the temperature constant for 20 minutes, and the air volume is 15m 3 / h; soaking section temperature 1150°C, time 5min, air volume 15m ...

Embodiment 3

[0042] Get 5kg vanadium-containing titanium magnetite, wherein 55wt% TFe, 10wt% TiO 2 , 8wt% (CaO+MgO+SiO 2 +Al 2 o 3 ), the particle size below 0.074mm accounts for more than 80%. Based on vanadium-titanium-magnetite, 30g of composite binder and 50g of additives are added externally according to mass percentage, stirred on a mixer for 6 minutes, and then 4% water is added externally, and stirred for 10 minutes. Ball the mixture in a disc pelletizer, sieve, put 10-12mm green balls into a roasting cup, use liquefied petroleum gas to oxidize and roast according to the following roasting system: drying starts from room temperature, heats up to 300 °C, and keeps the temperature constant 10min, air volume 35m 3 / h; then heat up to 1000°C, keep the temperature constant for 10 minutes, and air volume 15m 3 / h; continue to heat up to 1300 ℃, constant temperature for 15 minutes, air volume 15m 3 / h; soaking section temperature 1150°C, time 5min, air volume 15m 3 / h, then cool to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com