Preparation method of vanadium-titanium iron ore concentrate magnetized pellet

A technology of vanadium-titanium-iron concentrate and pellets, which is applied in the field of preparation of vanadium-titanium-iron concentrate magnetized pellets, can solve the problems that the reduction process of blast furnace and shaft furnace can not be carried out normally, and achieve improved desulfurization effect, simple process steps, Eliminates the effect of catastrophic inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

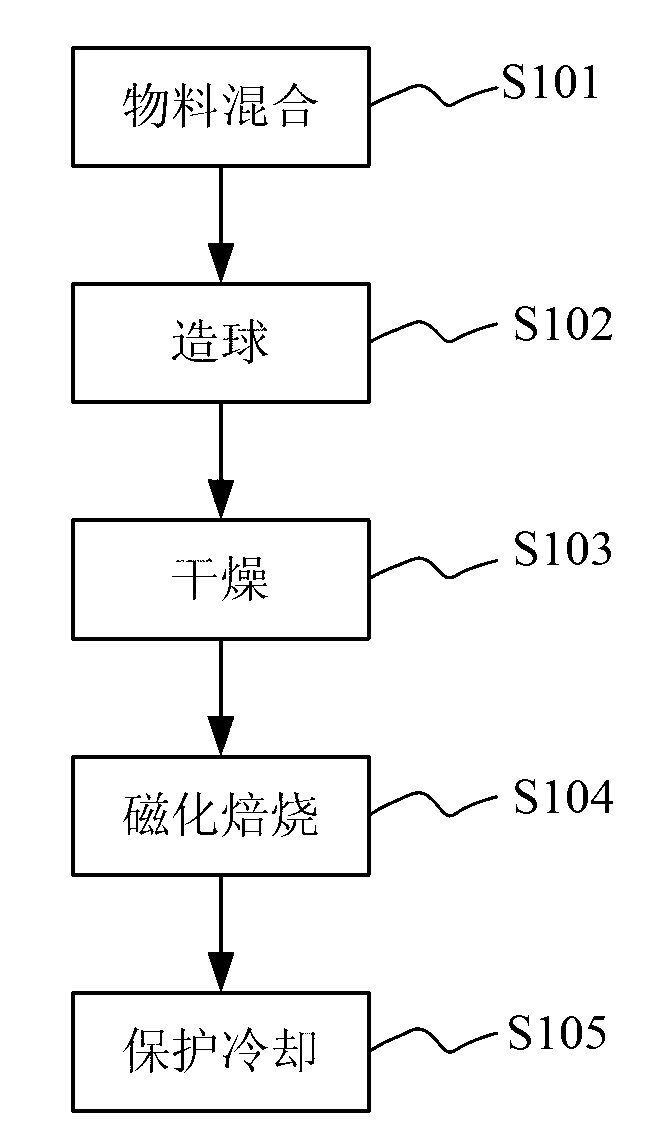

[0032] The preparation method of the vanadium-titanium-iron concentrate magnetized pellets provided by the embodiment of the present invention comprises:

[0033] Step S101: mixing materials;

[0034] The materials are mixed evenly, and the weight ratio of the materials is:

[0035] Vanadium-titanium iron ore concentrate powder: carbonaceous reducing agent: binder: additive: water = 100: (1-4): (2-9): (1-3): (5-8).

[0036] Step S102: making pellets;

[0037] Pelletizing the mixed materials to obtain green pellets, specifically, the pelletizing equipment can be a pressure molding machine, the molding pressure is 8-20MPa, the particle size of the green pellets is 15mm-30mm, the green pellets It is ellipsoidal or pillow-shaped, and the particle size of the green pellets refers to the largest radial dimension of the green pellets.

[0038] Step S103: drying;

[0039] The green pellets are dried, and the green pellets can be dried in a blast drying oven. The drying temperature...

Embodiment 1

[0048] Mix vanadium-titanium iron ore concentrate powder, carbonaceous reducing agent, binder, additives, and water according to the following weight ratio: vanadium-titanium-iron ore concentrate powder: carbonaceous reducing agent: (organic binder + bentonite): Additives: water=100:1:(1+6):1:6; the particle size of vanadium-titanium iron concentrate is -200 mesh, accounting for 58%, the organic binder is PVA, and the additive is B-containing 2 o 3It is 8% ferroboron concentrate. The mixture was pressed into a flat spherical shape on a pressure molding machine with a pressure of 15 MPa and a maximum radial dimension of the pellets of 20 mm. The green pellets were dried in a blast drying oven at a drying temperature of 150°C and a drying time of 60 minutes. The calcination temperature is 1200° C., and the calcination time is 60 minutes to obtain magnetized pellets, which are cooled under nitrogen protection. After testing, the magnetic susceptibility of the obtained magnetiz...

Embodiment 2

[0050] Mix vanadium-titanium iron ore concentrate powder, carbonaceous reducing agent, binder, additives, and water according to the following weight ratio: vanadium-titanium-iron ore concentrate powder: carbonaceous reducing agent: (organic binder + bentonite): Additives: water=100:2:(2+4):3:6; the particle size of vanadium-titanium iron concentrate is -200 mesh, accounting for 58%, the organic binder is PVA, and the additive is B-containing 2 o 3 It is 5% ferroboron concentrate. The mixture was pressed into a flat spherical shape on a pressure molding machine with a pressure of 12 MPa and a maximum radial dimension of the pellets of 20 mm. The green pellets were dried in a blast drying oven at a drying temperature of 250°C and a drying time of 40 minutes. The calcination temperature is 1150° C., and the calcination time is 80 minutes to obtain magnetized pellets, which are cooled under nitrogen protection. After testing, the magnetic susceptibility of the obtained magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com