Controlled aluminum electrolysis cell anode covering sealing structure

A technology of anode covering and sealing structure, applied in the field of controllable aluminum electrolytic cell anode covering and sealing structure, new aluminum electrolytic cell, to achieve the effect of changing electrolysis effect, good heat preservation effect, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

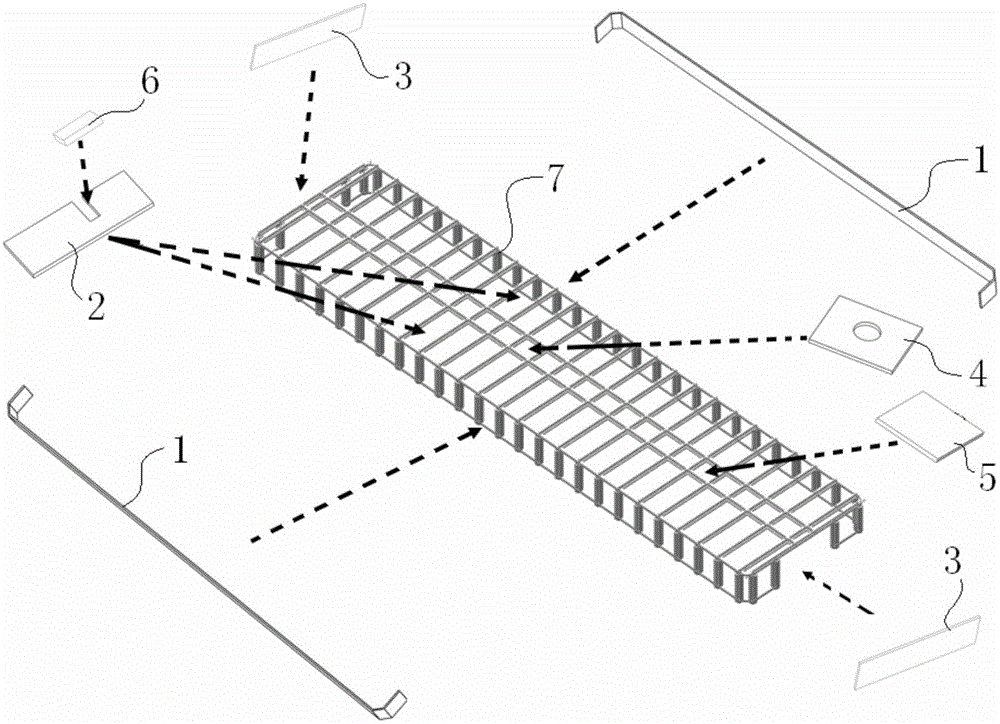

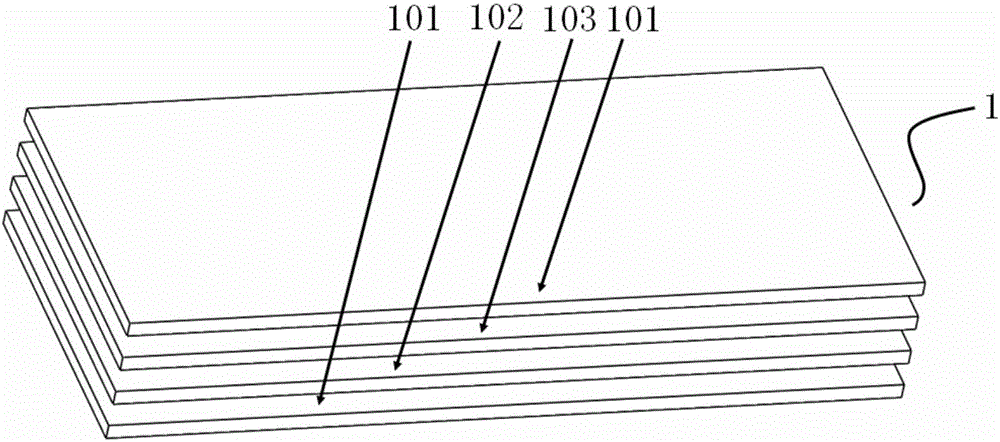

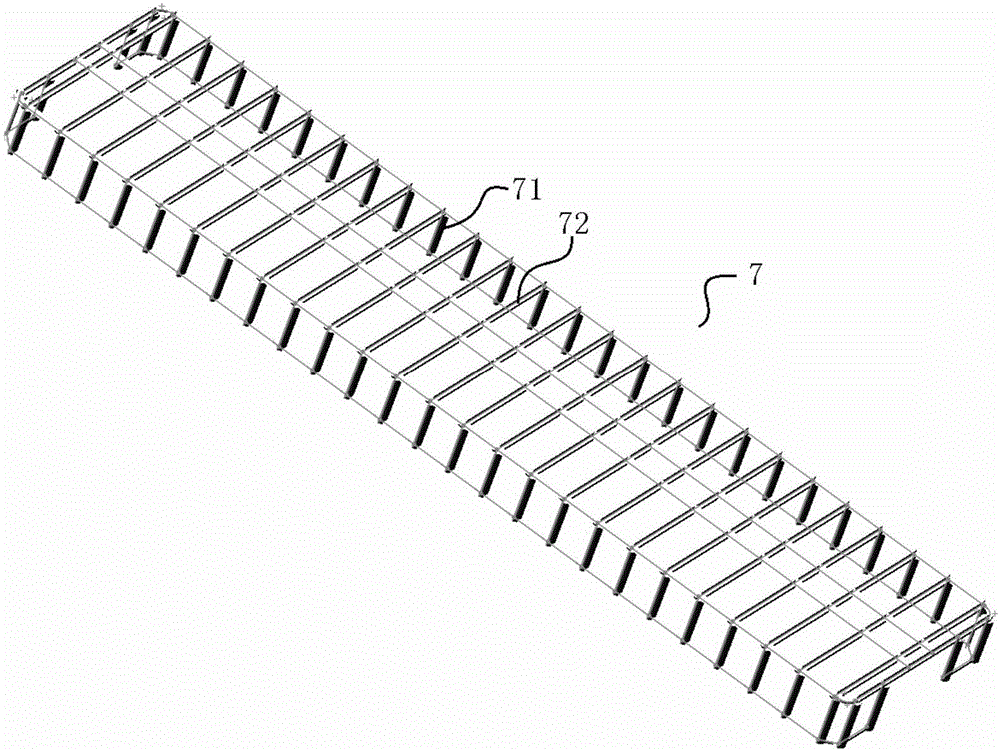

[0038] see figure 1 , the controllable aluminum electrolytic cell anode covering and sealing structure in the illustration is a preferred embodiment of the present invention, specifically including a structural frame 7 with a fixed cover arranged on the electrolytic cell, and a large side sealing plate laid on the structural frame 7 1. The upper anode seam sealing plate 2, the end sealing plate 3, the feeding opening sealing plate 4 and the anode middle seam sealing plate 5, wherein the structural frame made of stainless steel is fixed on the electrolytic cell, and the composite material sealing plate of different shapes Installed at its corresponding position to form a controllable alternative covering material structure with good sealing and heat insulation.

[0039] see in conjunction Figure 5 to Figure 9 , the large side sealing plate 1 is fixedly laid on the long side of the structural frame, the end sealing plate 3 is movably laid on the short side end face of the stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com