Double-layer paver ironing device with cleaning function

A paver and double-layer technology, which is applied to the field of ironing devices for double-layer paver, can solve the problems of reduced pavement flatness, impact on road construction quality, scratched pavement, etc. Save time and labor, take up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below through specific examples.

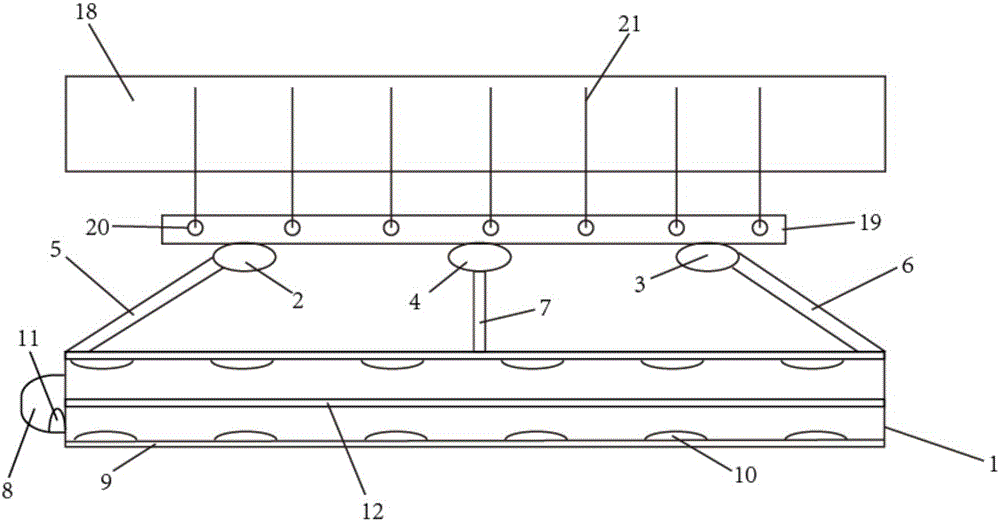

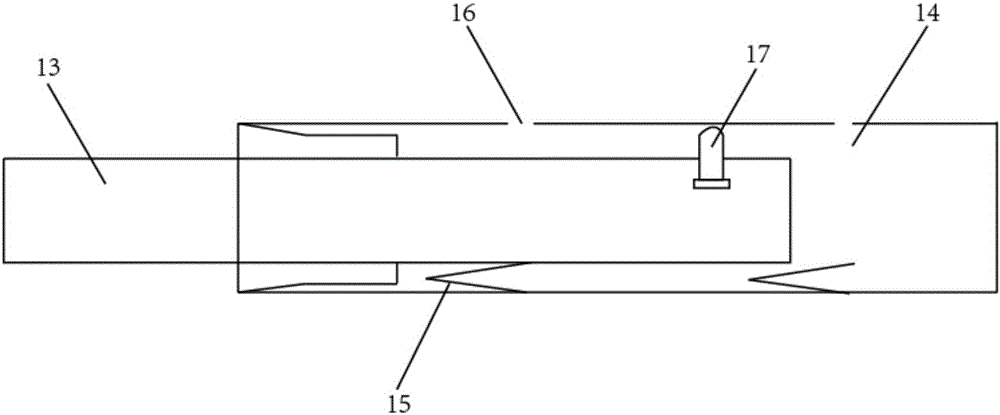

[0015] Double-layer paver ironing device with cleaning function, including outer layer ironing plate 18, ironing plate main body 1, left oil cylinder 2, right oil cylinder 3, middle oil cylinder 7 and cleaning device, outer layer ironing plate 18 passes through the fixing plate 19 is connected with the main body 1 of the ironing plate, and a rotating device is provided on the fixed plate 19. The rotating device includes a rotating shaft 20 and a rotating rod 21. The rotating shaft 20 is arranged on the outside of the fixed plate 19, the left side of the ironing plate main body 1 is connected with the left oil cylinder 2 through the left force applying part 5, the right side of the ironing plate main body 1 is connected with the right oil cylinder 3 through the right force applying part 6, and the ironing plate The middle part of the main body 1 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com