Traffic cableway bridge reinforced concrete bridge deck slab

A technology for bridge decks and car dealerships, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of poor durability of bridge deck components, poor bridge deck traffic performance, etc., and achieve convenient on-site assembly and construction, simple structure, and durability of components. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

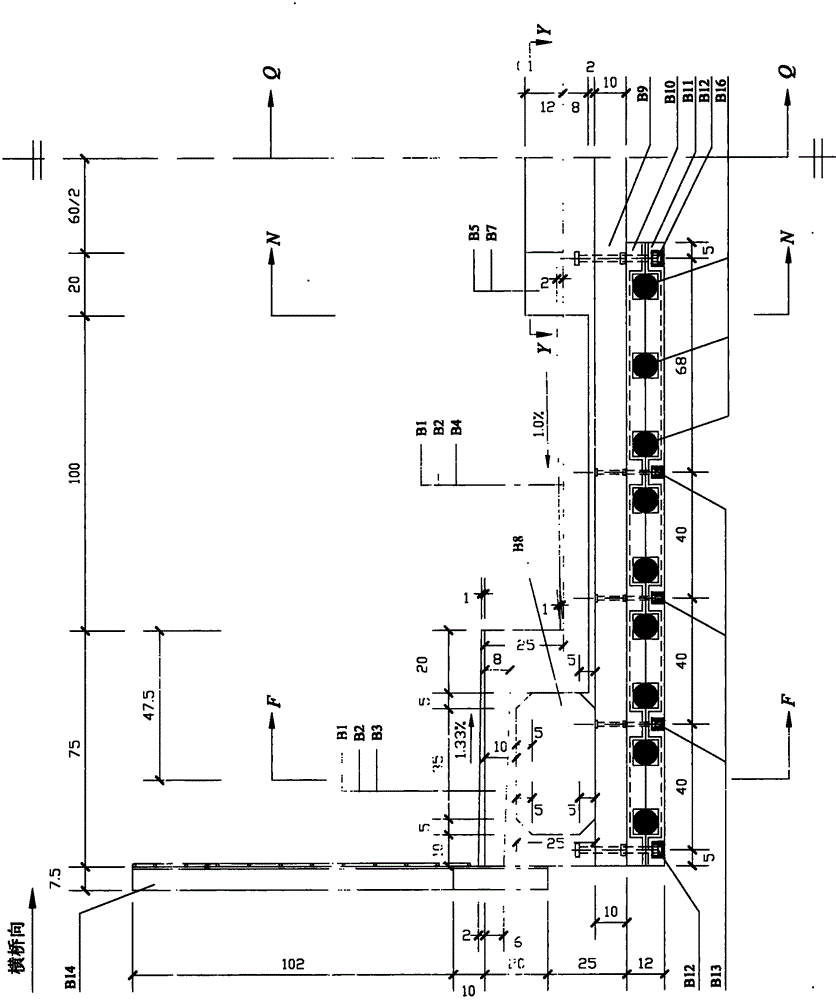

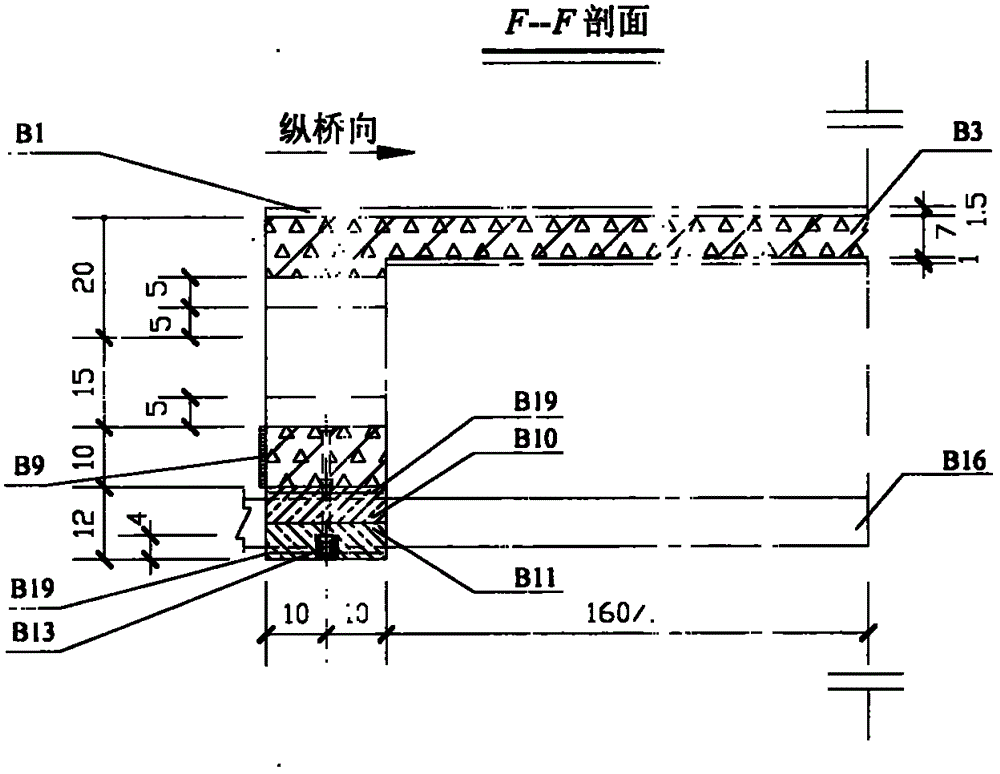

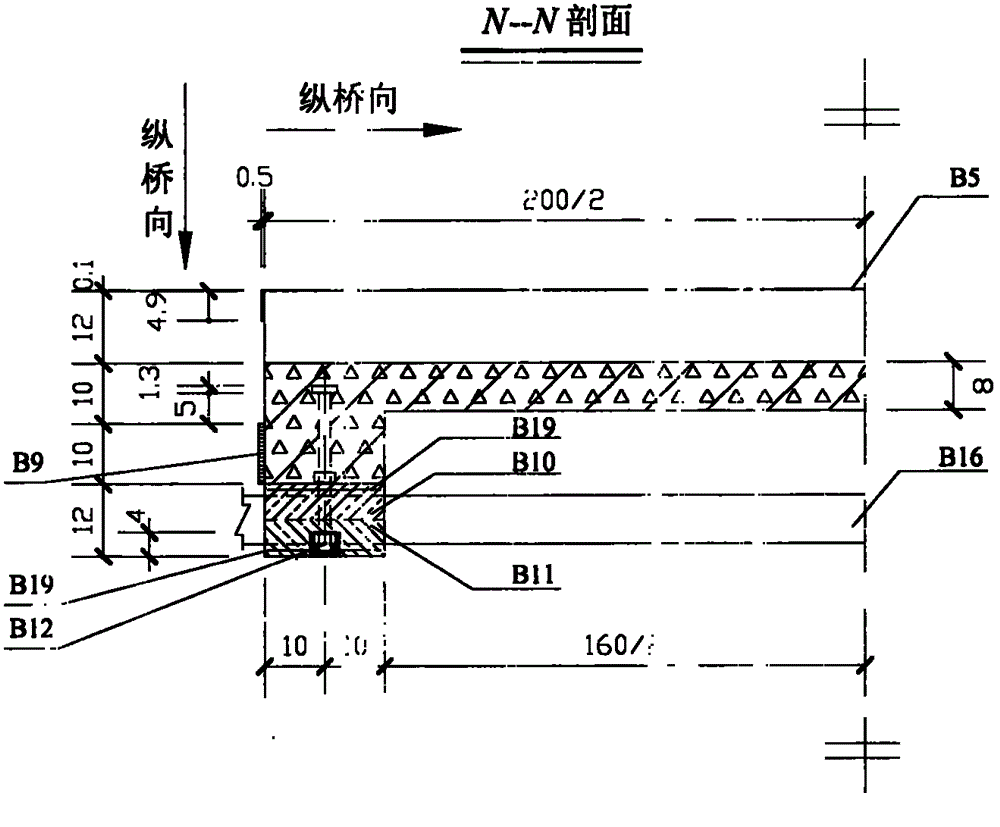

[0043] This embodiment is suitable for the construction of ordinary bridge plates. Taking a cableway bridge with a main span of 438m as an example, the design vehicle load model is 3×550kN, and the distance between vehicles is 150m.

[0044] like figure 1 As shown, the deck structure layers of the sidewalk are asphalt sand wear layer (B1), JBS waterproof coating (B2), and C40 reinforced concrete sidewalk slab (B3) from top to bottom. The C40 reinforced concrete sidewalk slab (B3) is a variable-thickness cantilever slab, and the thickness of the cantilever end and root are 6cm and 8cm respectively. The bridge deck structural layers of the carriageway are asphalt sand wear layer (B1), JBS waterproof coating (B2), and C40 reinforced concrete carriageway slab (B4) from top to bottom. The thickness of the C40 reinforced concrete roadway slab (B4) is 8cm. The JBS waterproof coating (B2) should be applied after the bridge deck joint structure is installed, and the asphalt sand abr...

Embodiment 2

[0056] This embodiment is suitable for the construction of the beam deck. Taking a cableway bridge with a main span of 438m as a design example, the design vehicle load is 3×550kN and the distance between vehicles is 150m.

[0057] like Figure 23 , Figure 24 ,and Figure 25 As shown, most of the structures in the cross-section of the beam bridge deck are the same as those of the ordinary bridge deck, and its longitudinal bridge length is equal to the top surface width of the upper flange of the I50c steel beam (B28) supporting it. Its central part is no longer provided with a hole-retaining area, but the central opening side stringer (B7) remains to form an inner curb that guides the wheels to travel in a limited area. The beam zinc-iron cover plate (B5 ') is also much shorter than the common zinc-iron cover plate (B5), but its upper surface will still be painted with black road reflective paint strips (B17) and yellow road reflective paint strips (B18). Use M12×260-Q sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com