A modular assembled L-shaped cold-formed thin-walled steel composite wall and its connection method

A cold-formed thin-walled steel, prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of difficulty in achieving horizontal and vertical connections, staying in the degree of assembly, and difficult to combine walls with performance. The effect of improving horizontal installation efficiency, reducing assembly difficulty, and improving horizontal shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

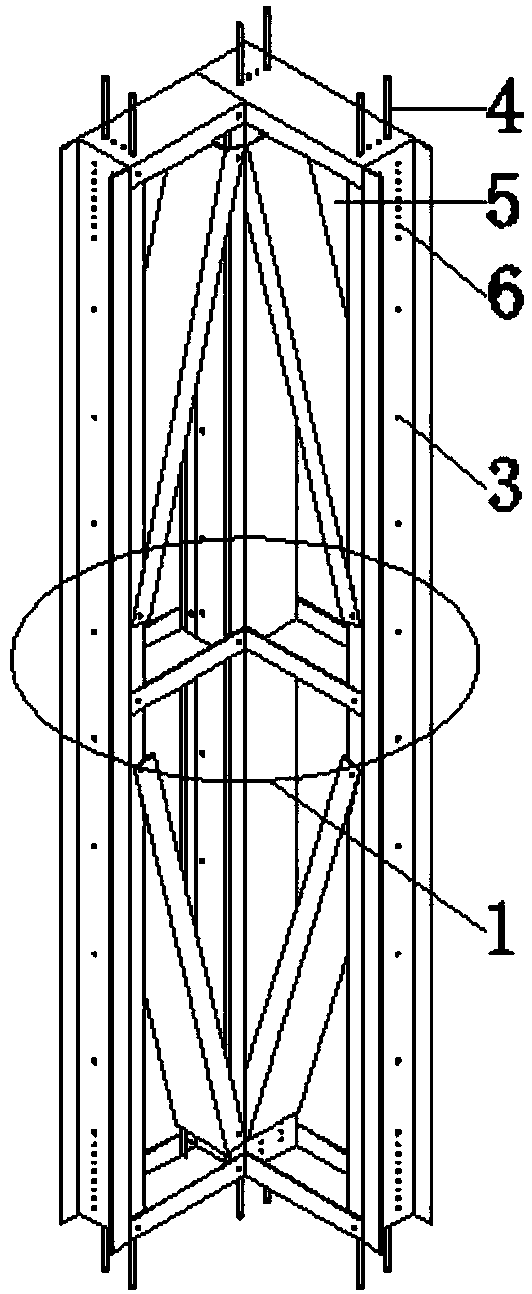

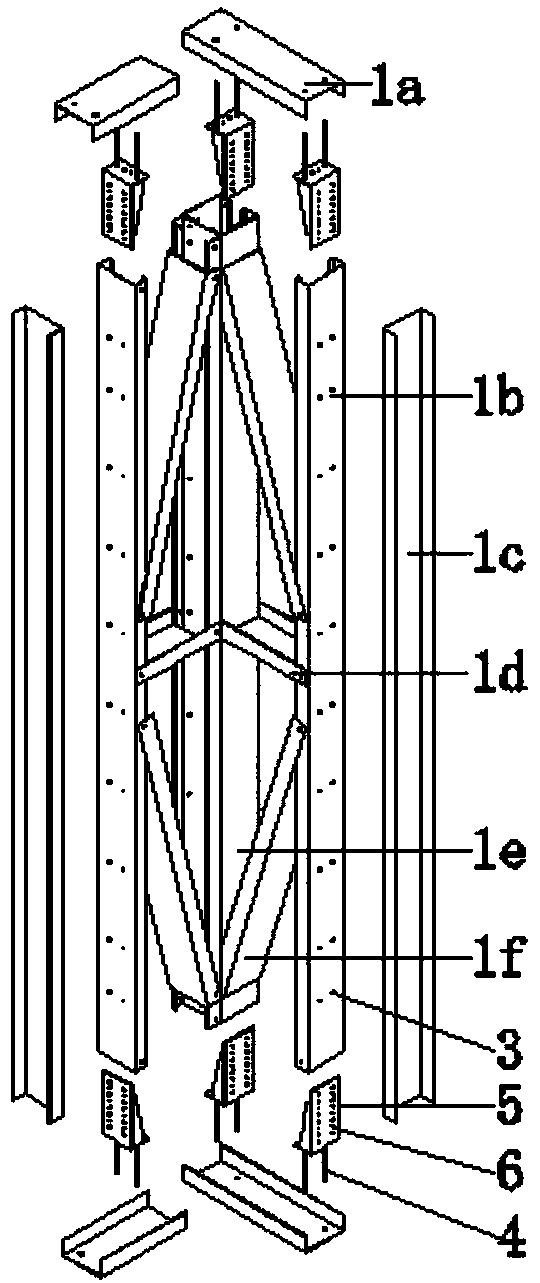

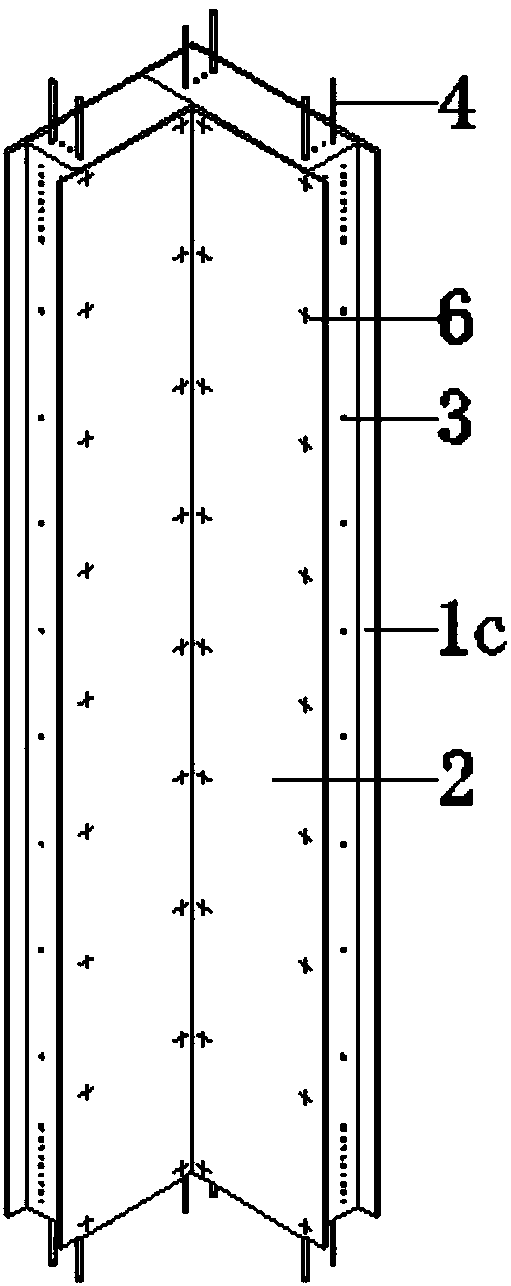

[0033] The production method of the modular assembled L-shaped cold-formed thin-walled steel composite wall:

[0034]During the specific implementation, firstly, the required C-shaped steel is cut and processed in the factory, and the attached Figure 5 The C-shaped steel is connected by lock riveting to form a combined section corner column (1e), and then the U-shaped transverse guide rail (1a), C-shaped vertical side column (1b), U-shaped vertical connector (1c), U-shaped horizontal support (1d), C-shaped diagonal brace (1f), the above six components are attached figure 1 in the form of pre-positioning on the factory assembly line, according to the attached figure 2 , 3 Lock riveting layout plan is connected by lock riveting to form L-shaped cold-formed thin-walled steel skeleton (1);

[0035] The above-mentioned L-shaped cold-formed thin-walled steel frame (1) is attached figure 2 Install the vertical anti-pull connector (5) in place, and fix the vertical anti-pull co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com