Method for designing main roadway coal pillar recycling scheme

A design method and scheme technology, which can be used in earth drilling, surface mining, underground mining, etc., and can solve problems such as mining roadway layout, difficulty in mining, and high support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

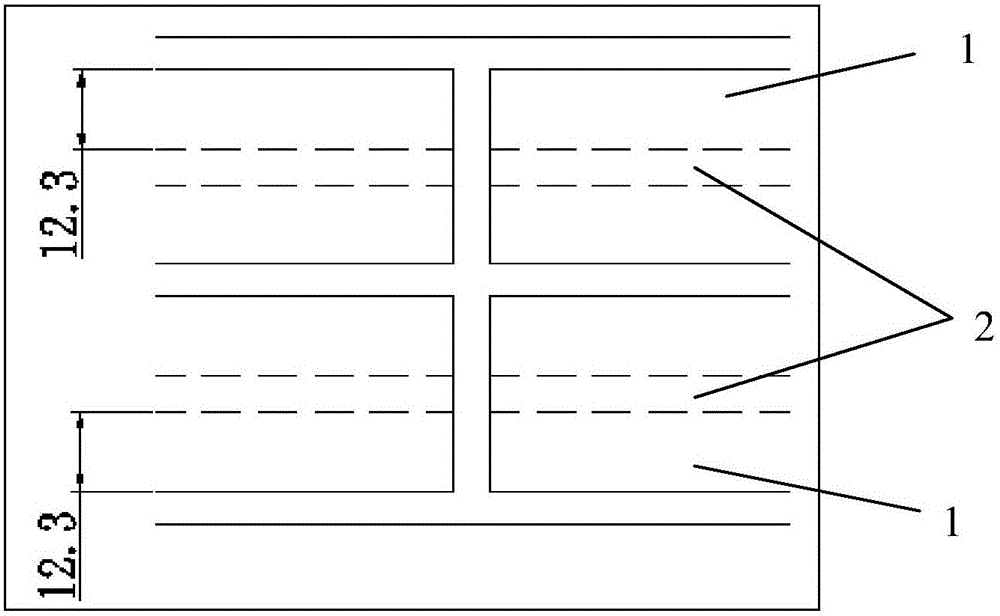

[0029] Attached below picture To further illustrate the specific implementation of the present invention.

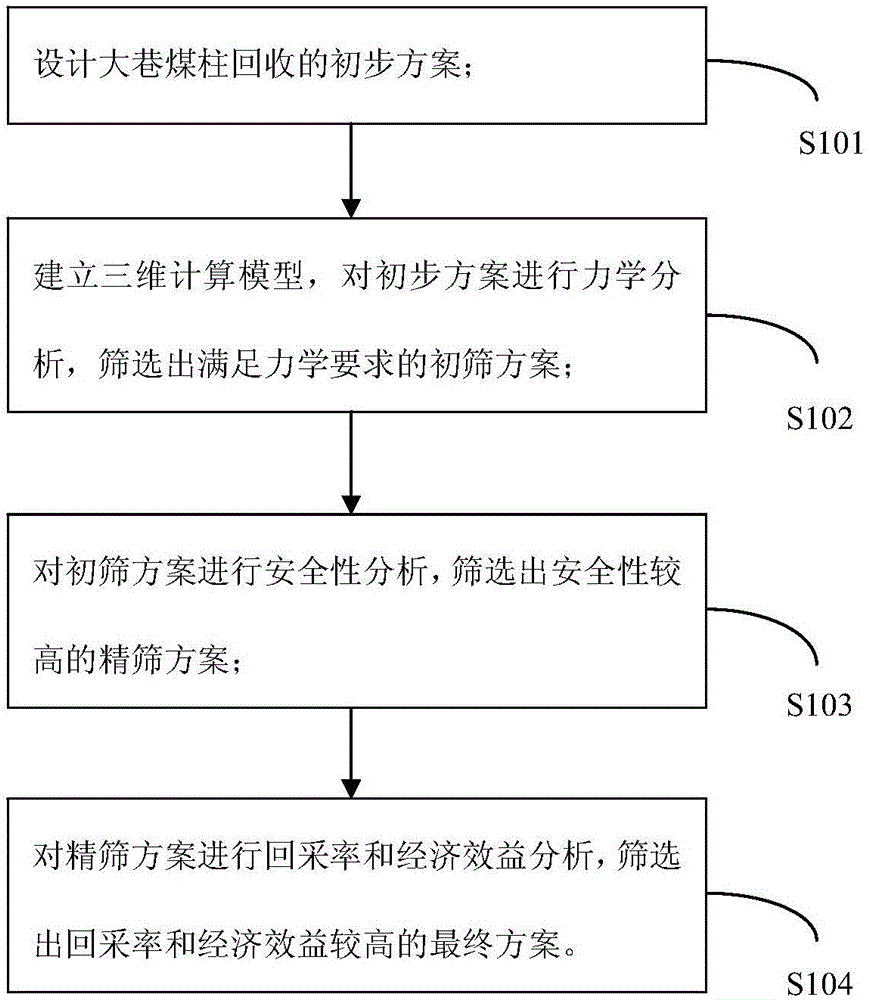

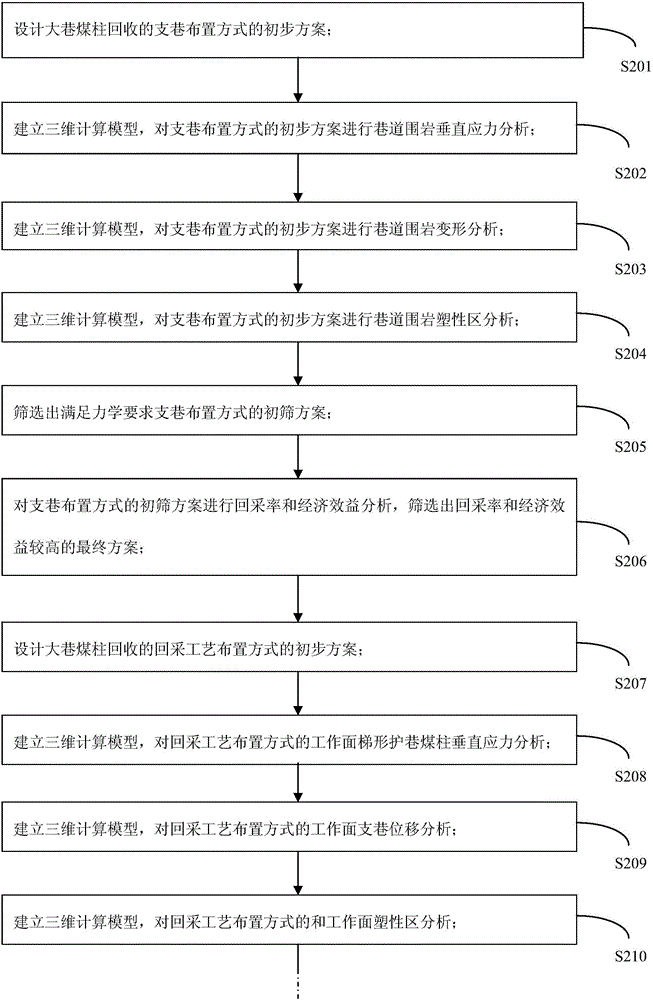

[0030] Such as figure 1 As shown, it is the flow process of the design method of the roadway coal pillar recovery scheme in an embodiment of the present invention picture , including the following steps:

[0031] Step S101: designing a preliminary scheme for coal pillar recovery in the main road;

[0032] Among them, the preliminary plan includes the arrangement of branch roads, the arrangement of mining technology and the management of the roof.

[0033] Step S102: Establish a three-dimensional calculation model, perform mechanical analysis on the preliminary scheme, and select a preliminary screening scheme that meets the mechanical requirements;

[0034] Among them, the mechanical analysis of branch roadway layout includes: vertical stress analysis of roadway surrounding rock, deformation analysis of roadway surrounding rock and plastic zone analysis of roadway s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com