Multistage screen type automobile tail gas collecting device

A technology of automobile exhaust and collection devices, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., can solve the problems of poor operability, low efficiency and complexity of automobile exhaust absorption, and reduce air pollution and increase air pollution. The effect of liquid exchange efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

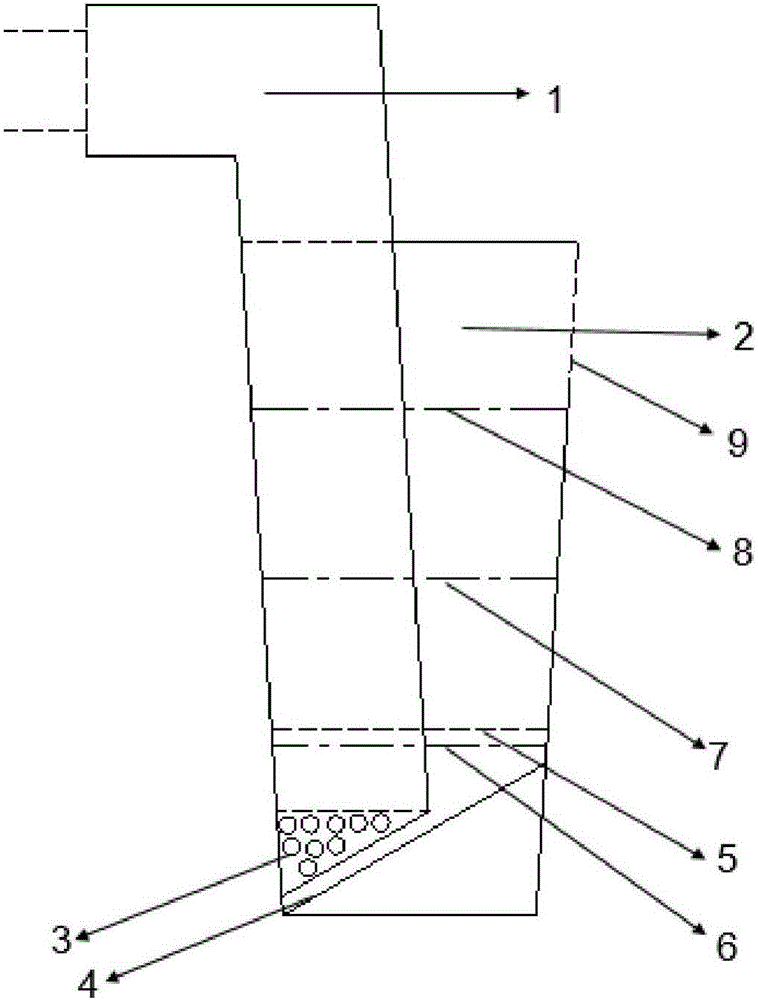

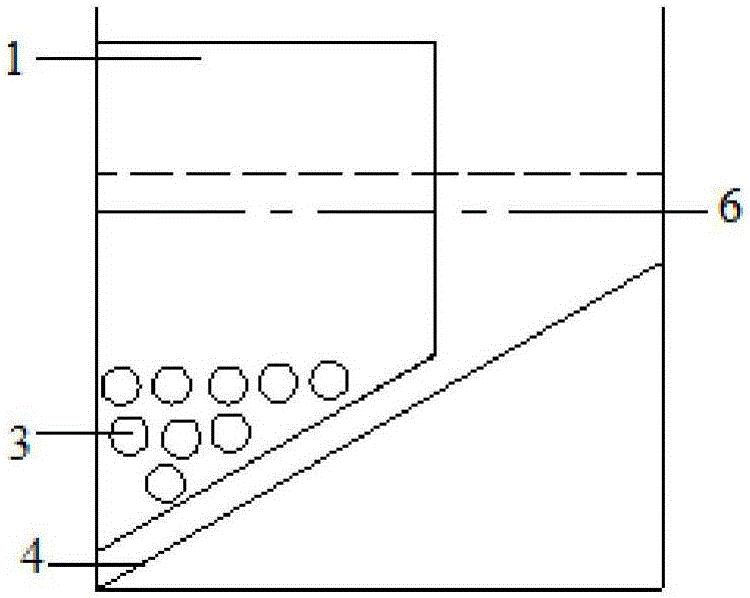

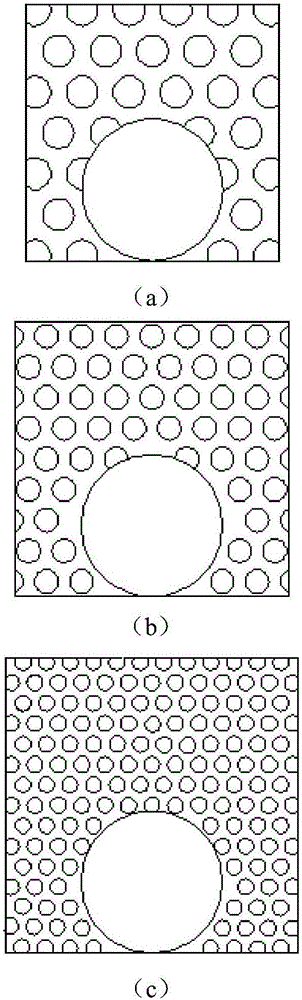

[0018] Such as figure 1 As shown, the multi-stage screen type automobile exhaust gas collection device of the present embodiment comprises: intake pipe 1, reaction box 2, inclined partition 4, exhaust gas collection liquid 5, first to third stage screens 6-8 and exhaust Mouth 9; Wherein, in the bottom of reaction box 2, inclined dividing plate 4 is set, and the included angle of inclined dividing plate and horizontal plane is 30 °, and the outer edge of inclined dividing plate is connected with the inwall sealing of reaction box; The inclined dividing plate in reaction box Exhaust gas collection liquid 5 is placed on the separator 4; the first to third stage screens 6-8 are arranged sequentially in the reaction box from bottom to top; one end of the intake pipe 1 is connected to the exhaust pipe of the car, and the other end The air intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com