Temperature rise control system of high-pressure liquefied hydrocarbon pump

A control system, technology of liquefied hydrocarbons, applied in parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve problems affecting the self-flushing pressure stability of mechanical seals, leakage, mechanical seal damage, etc., to achieve Improve operational reliability and service life, reduce energy consumption, and reduce flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

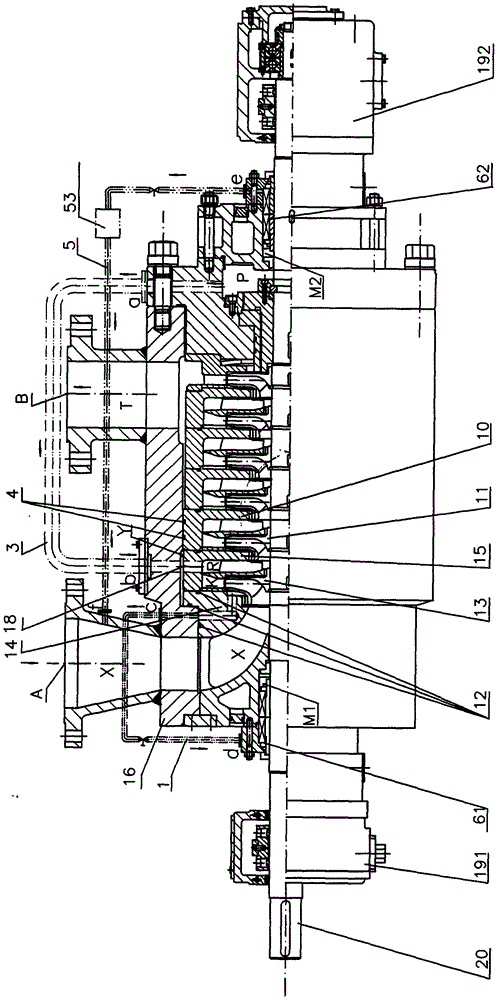

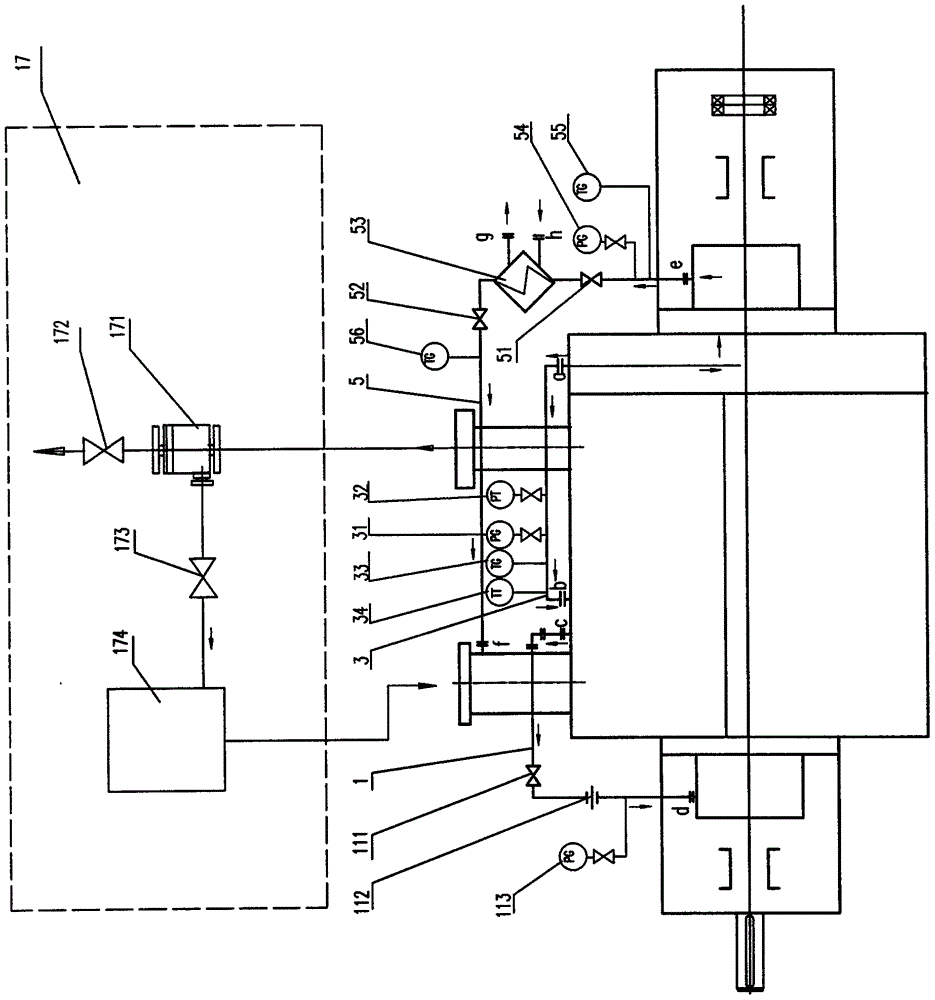

[0014] Such as figure 1 , figure 2 As shown, the temperature rise control system of the high-pressure liquefied hydrocarbon pump of the present invention includes an axial force balance mechanism and a mechanical seal self-flushing mechanism. , second-stage middle section 10), impeller (including first-stage impeller 13, second-stage impeller 11), balance drum 7 (and balance drum sleeve 8), suction body 14, pump cover 9, outer cylinder 16, the mechanical seal is self- The flushing mechanism includes forward flushing pipe assembly 1, reverse flushing pipe assembly 5, mechanical seal components (including driving side mechanical seal assembly 61 and non-driving side mechanical seal assembly 62), which has a balance chamber P (by the pump cover 9 Inner cavity, balance drum 7 and end face of balance drum sleeve 8), secondary impeller suction chamber R, suction chamber X, discharge chamber T, pump suction port A, pump discharge port B and driving side sealing chamber M1 , Non-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com