Scrap steel shear fast hydraulic system

A hydraulic system, fast technology, applied in the direction of fluid pressure actuating device, servo motor, servo meter circuit, etc., can solve the problems of increasing fault occurrence, difficult dynamic compensation, large impact of hydraulic and mechanical devices, etc. , the effect of faster response, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

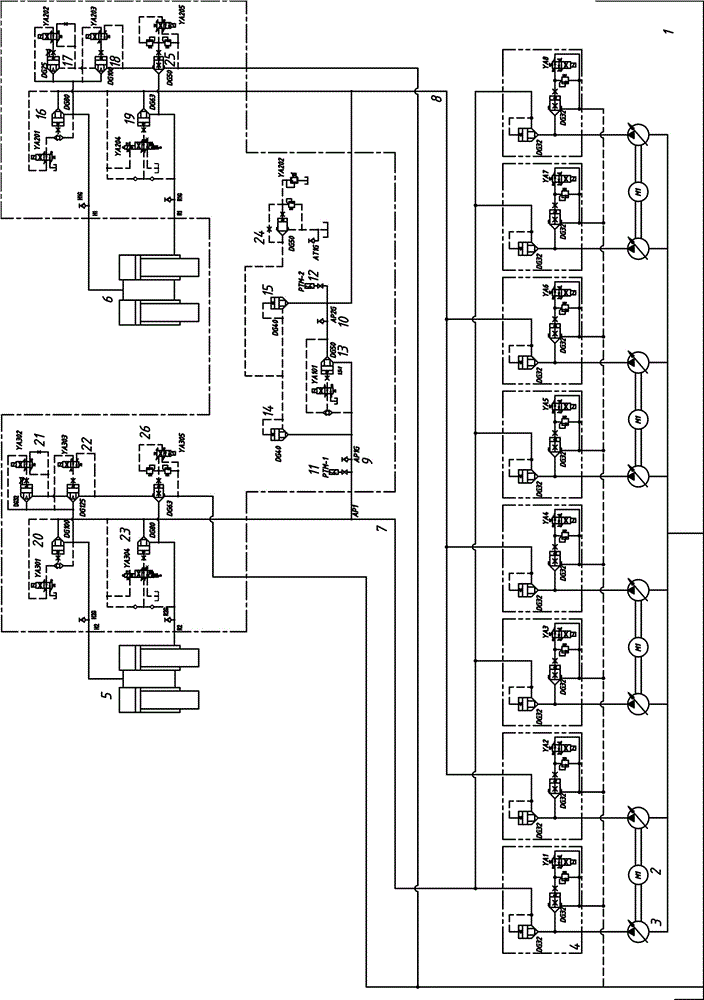

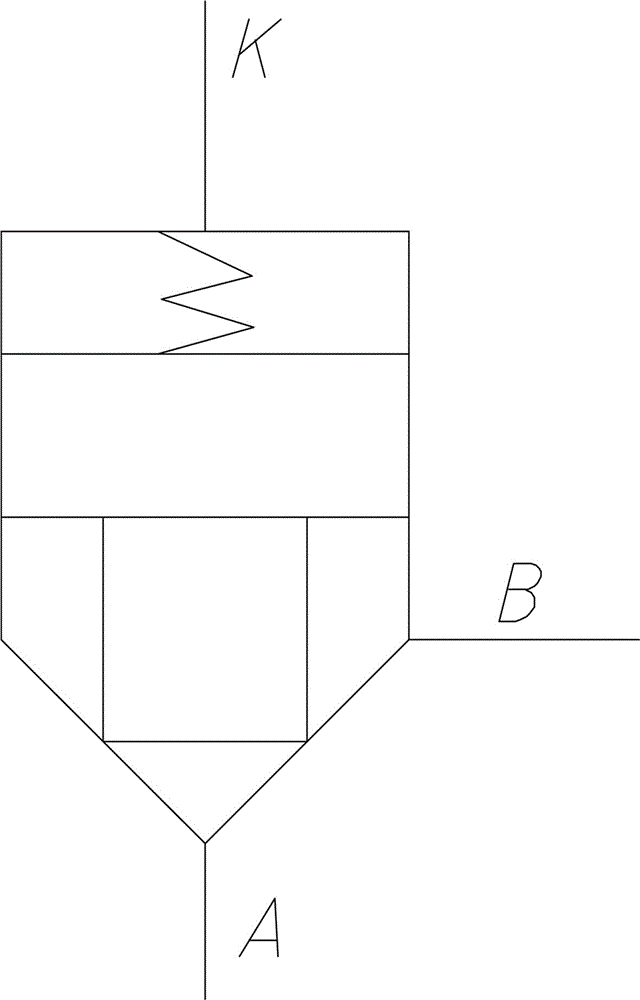

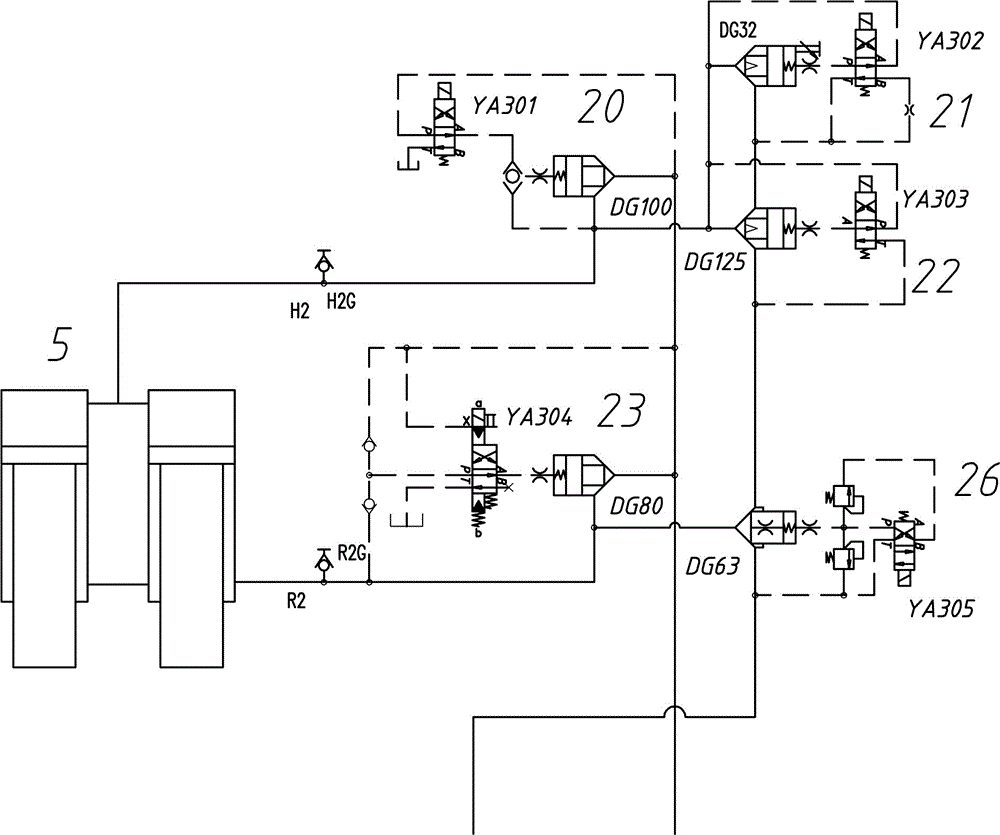

[0037] Such as Figure 1~5 Among them, a rapid hydraulic system for scrap steel shearing, a plurality of oil pumps 3 are respectively connected to the first oil inlet 7 and the second oil inlet 8; this structure facilitates the control of hydraulic oil flow according to working conditions.

[0038]In a preferred solution, the plurality of oil pumps 3 are respectively connected to the motor 2, the motor 2 adopts a frequency conversion double extension shaft motor, and each double extension shaft motor is connected to two oil pumps. Based on this structure and dynamic configuration according to working conditions, energy consumption can be further saved.

[0039] The system of the present invention is conventionally used in the rapid hydraulic system of 800-ton scrap steel shears. When it is used in 1250-ton scrap steel shears, the size of the plug-in directional valve does not need to be changed, only two sets of oil pumps and motor units need to be added to meet the requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com