Supporting structure used for measuring parameter influence characteristics of extrusion oil film damper

A technology of extruding oil film damping and supporting structure, which is applied in the direction of flexible bearings, rotating bearings, rigid supports of bearing components, etc. It can solve problems such as difficult measurement, non-adjustable parameters, and non-independent oil film outer ring, etc., to achieve convenience and accuracy The effect of measurement, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

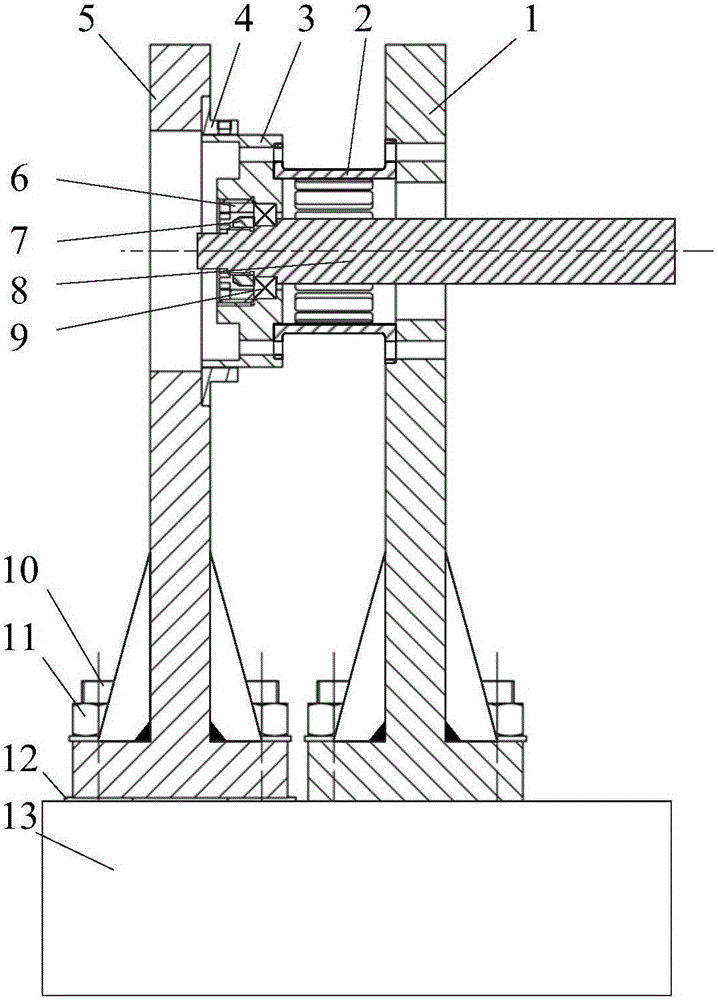

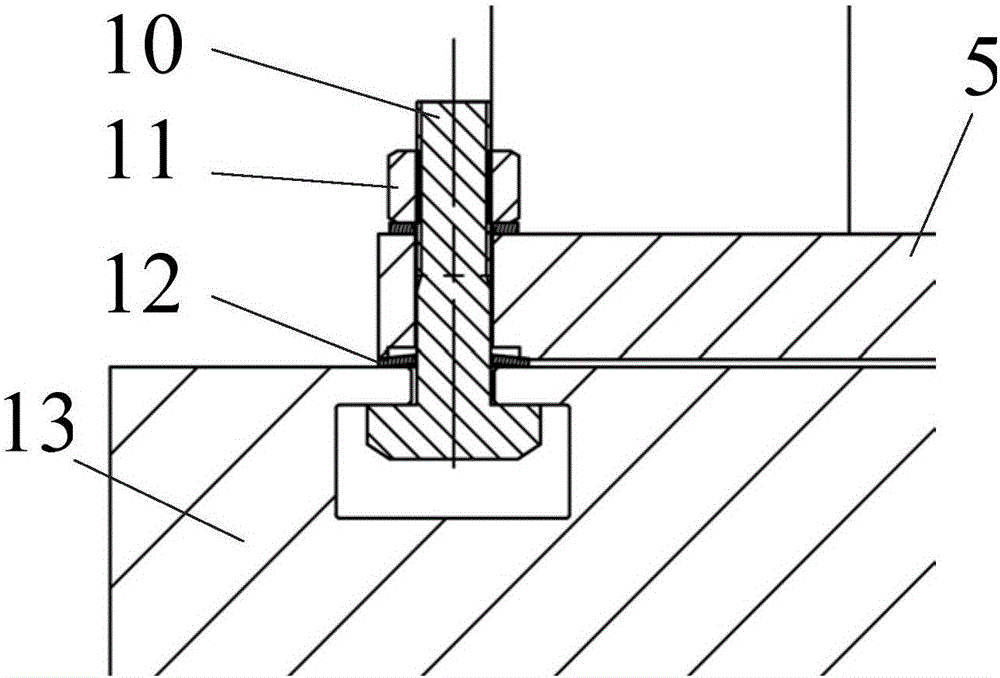

[0039] This embodiment is a supporting structure used to experimentally determine the influence characteristics of squeeze oil film damper parameters, including a base 13, a supporting seat 1, a squirrel-cage elastic support 2, a bearing seat 3, an oil film outer ring 4, and an independent bearing 5. , Disc spring 12 and adjusting bolt 10. among them:

[0040] Both the supporting base 1 and the independent supporting base 5 are respectively fixed on the base 13 with adjusting bolts 10 through “T”-shaped grooves, and are fastened by nuts 11. The center line of the center hole of the support seat coincides with the center line of the center hole of the independent support seat. A disc spring 12 is arranged between the bottom surface of the independent support and the upper surface of the base.

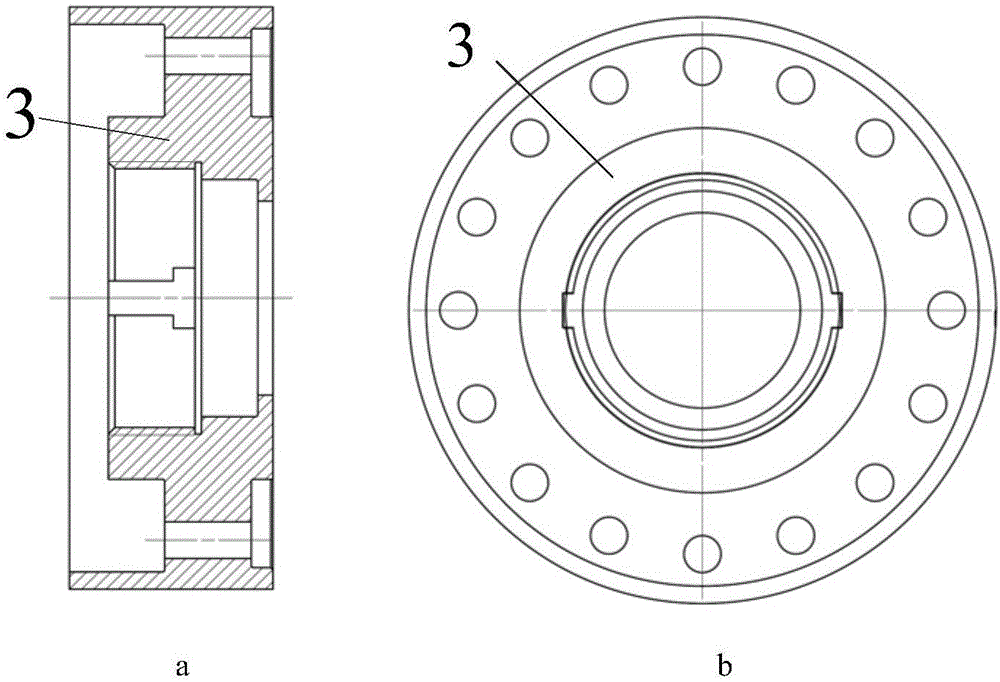

[0041] One end of the squirrel cage elastic support 2 is embedded on the support base 1, and the end surface of the squirrel cage elastic support 2 is in interference fit with the support b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com