Piston ring

A piston ring and ring body technology, applied in the field of piston rings, can solve the problems of piston ring sealing and wear resistance defects, gas blow-by, etc., and achieve the effect of improving the operating life and reducing the probability of overall structure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Table 1-2 shows the composition and performance parameters of the upper and lower ring bodies of the piston rings in Examples 1-4.

[0051] Table 1:

[0052]

[0053] Table 2:

[0054]

[0055] Through the above tests, the performance index of the obtained piston ring is better than that of the prior art, and its service life is greatly improved.

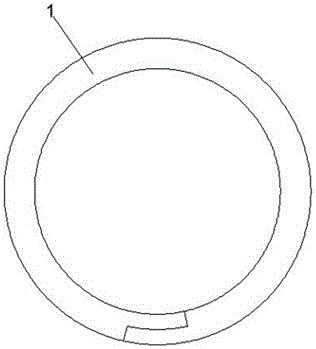

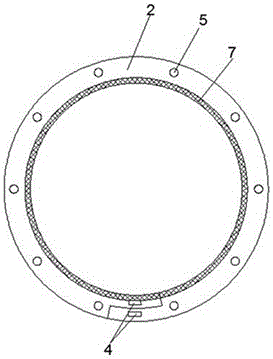

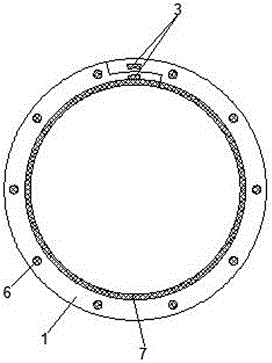

[0056] Attached below Figure 1-3 The structural improvement of the piston ring is described in detail.

[0057] The piston ring comprises an upper ring body 1 and a lower ring body 2, the upper ring body 1 and the lower ring body 2 are all provided with cross openings, the bottom surfaces of both ends of the upper ring body 1 are provided with bosses 3, and the lower ring body 1 The top surface of both ends of the body 2 is provided with grooves 4, and the boss 3 is connected with the groove 4. At the same time, the lower surface of the upper ring body 1 is evenly provided with a number of protruding rods 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com