Method for changing Babcock and Wilcox 1165 type boiler combustor combination

A boiler combustion and swirling burner technology, which is applied in the direction of combustion method, burner, burner for burning powder fuel, etc., can solve the problem of unsatisfactory mixing effect of wind and stable combustion pulverized coal, poor combustion economy, and reduced combustion efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings: It should be emphasized that the embodiments of the present invention are illustrative rather than restrictive, so the present invention is not limited to the implementation described in the specific embodiments. For example, all other implementations obtained by those skilled in the art according to the technical solution of the present invention also belong to the protection scope of the present invention.

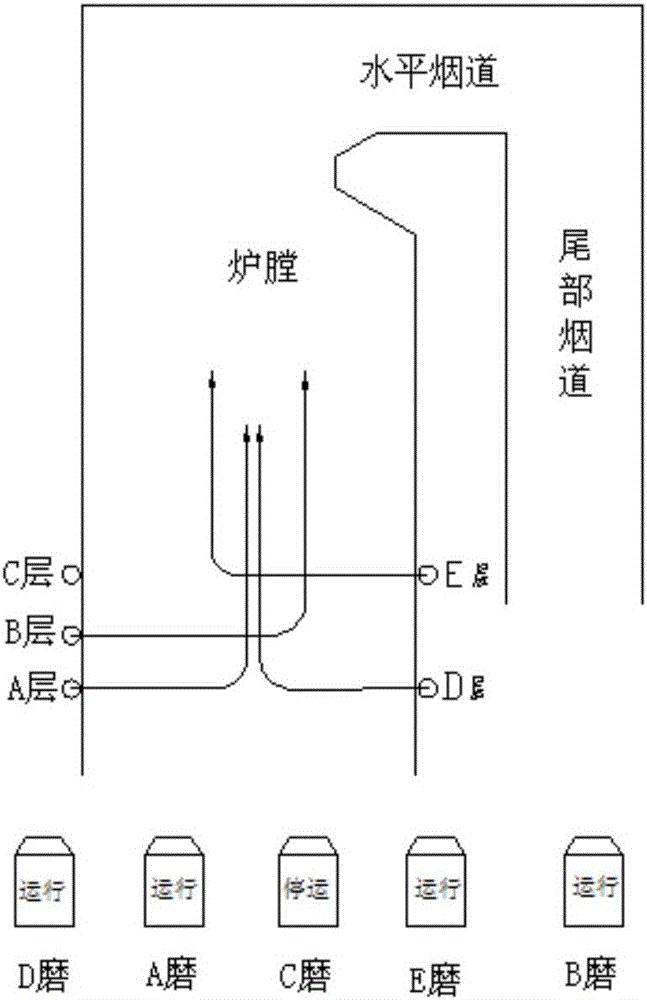

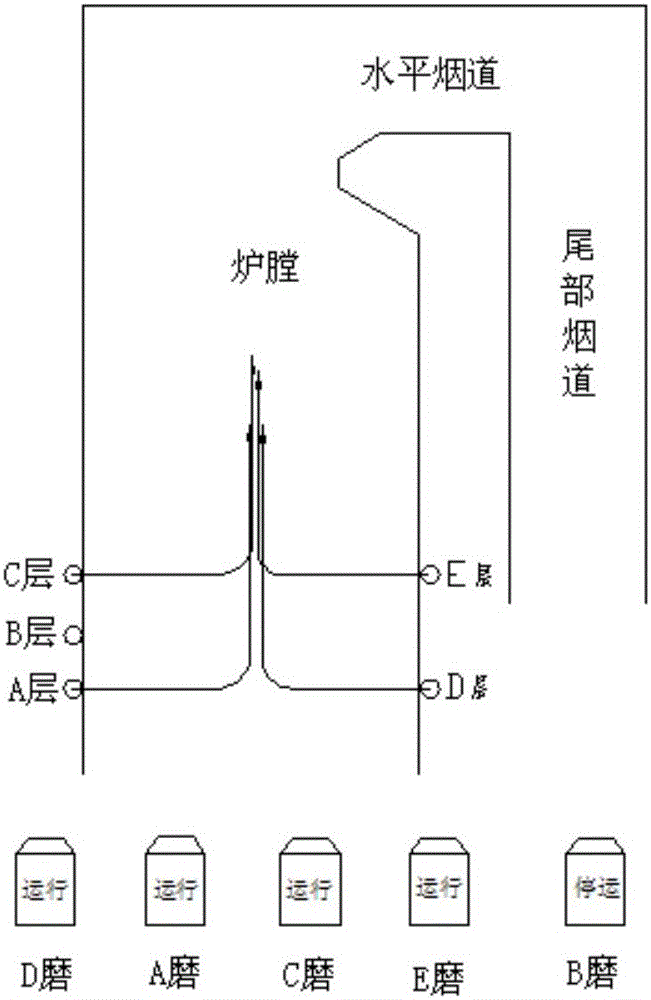

[0012] A method of changing the combination of boiler burners of Bawei 1165 type, such as figure 2 As shown, the innovation point of the present invention is that the front wall of the boiler is put into two layers of burners A and C, and the rear wall is put into two layers of burners D and E, corresponding to the mid Speed coal mill.

[0013] In the specific implementation of the present invention, the pulverized coal pulverized by A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com