Semi-automatic liquid crystal screen repairing machine

A technology of LCD screen and repair machine, applied in nonlinear optics, instruments, optics, etc., can solve problems such as non-conformance and expensive repair equipment, and achieve the effects of convenient use, improved repair efficiency, and reduced operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

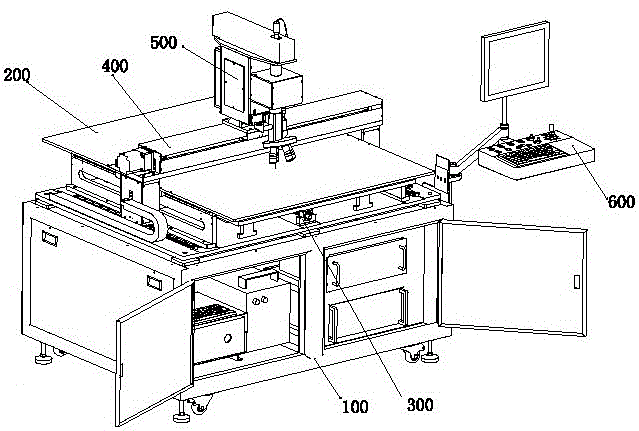

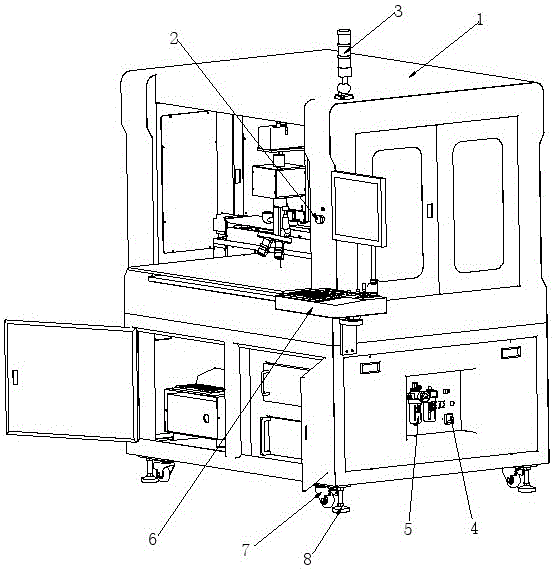

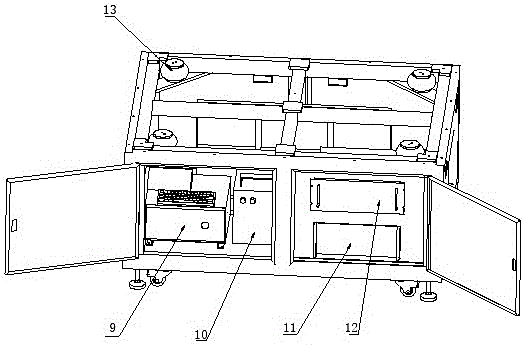

[0028] Referring to the accompanying drawings, a semi-automatic liquid crystal screen repairing machine of the present invention includes a frame 100, a workpiece carrying device 200, a Y-axis system 300, an X-axis system 400Z and a laser processing head 500, and is characterized in that:

[0029] The laser processing head 500 includes a laser processing device and a Z-axis screw system 37, the laser processing device is installed on the laser device mounting base 46, and the laser device mounting base 46 is composed of the Z-axis screw rod system 37 and the headstock 45 Screw nut transmission connection, the machine head seat 45 is installed on the machine head connecting plate 32 of the X-axis system 400;

[0030] The X-axis system 400 includes a machine head connection plate 32, an X-axis screw nut 33, an X-axis screw mandrel 31, an X-axis screw support seat 29, an X-axis beam 35 and a column 22. Fix the X-axis screw nut 33, the X-axis screw nut 33 and the X-axis screw 31 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com