Die back surface silicone printing encapsulation method

A packaging method and wafer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of complex manufacturing process, expensive raw materials, and high prices, so as to reduce costs, improve bonding quality, and avoid The effect of glue layer voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

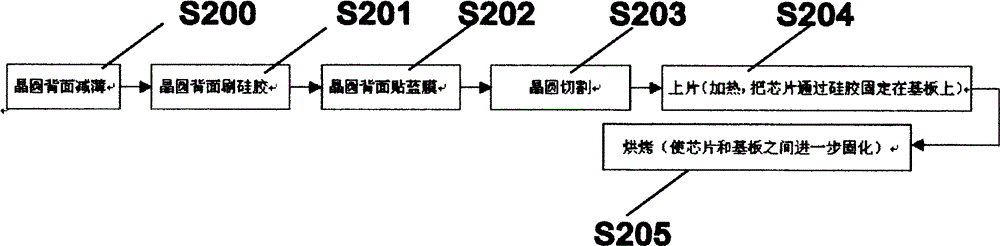

[0027] The present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

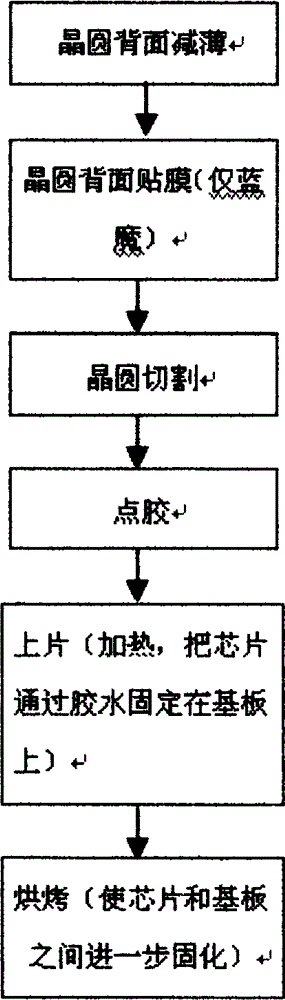

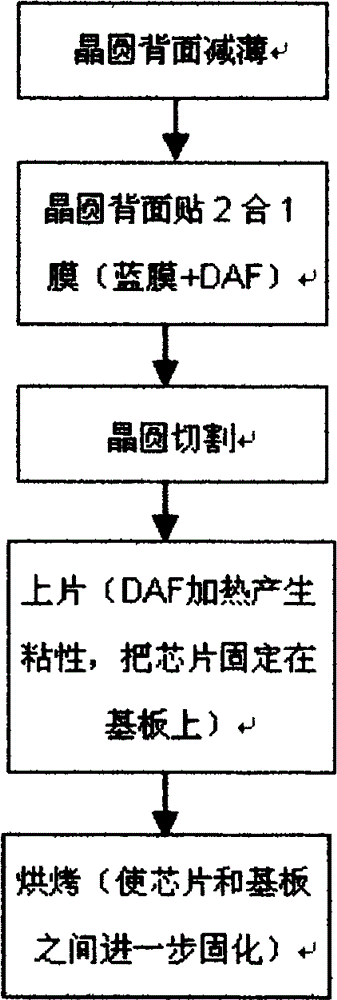

[0028] Such as figure 1 and figure 2 As shown, the existing method of wafer packaging in integrated circuits includes two conventional process methods, the first process: the wafer is pasted by DAF film, and the price remains high due to the complicated manufacturing process and expensive raw materials; and the second process In the second process, the wafer is pasted by the dispensing process. Because the dispensing process cannot ensure that the glue layer is uniform, it is easy to produce cavities. Especially for large chips, the probability of cavities is higher, and the cavities are larger, causing serious damage to subsequent processes. Interference poses a great risk to the stability of produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com