Switched reluctance motor direct instantaneous torque control method based on voltage vectors

A technology of switched reluctance motor and voltage vector, which is applied in motor generator control, electronically commutated motor control, torque ripple control, etc. It can solve problems such as cumbersome calculation, excessive peak value of phase current, and great influence on control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

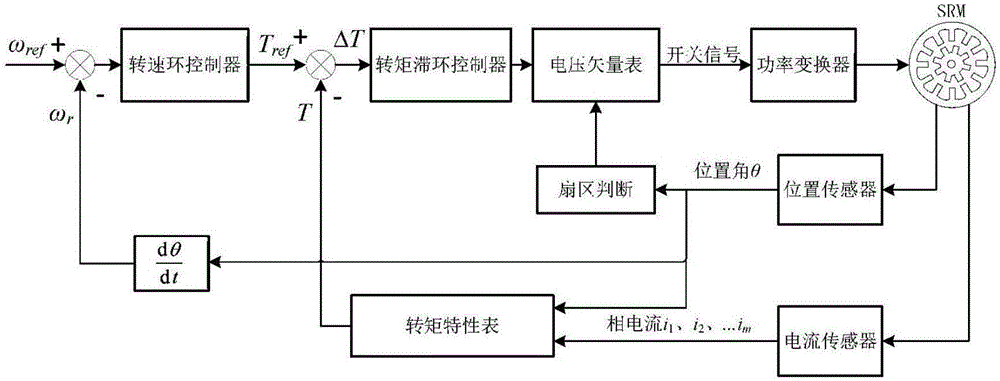

[0065] The direct instantaneous torque control method of switched reluctance motor based on voltage vector of the present invention, its control block diagram is as follows figure 1 As shown, its specific implementation steps are as follows:

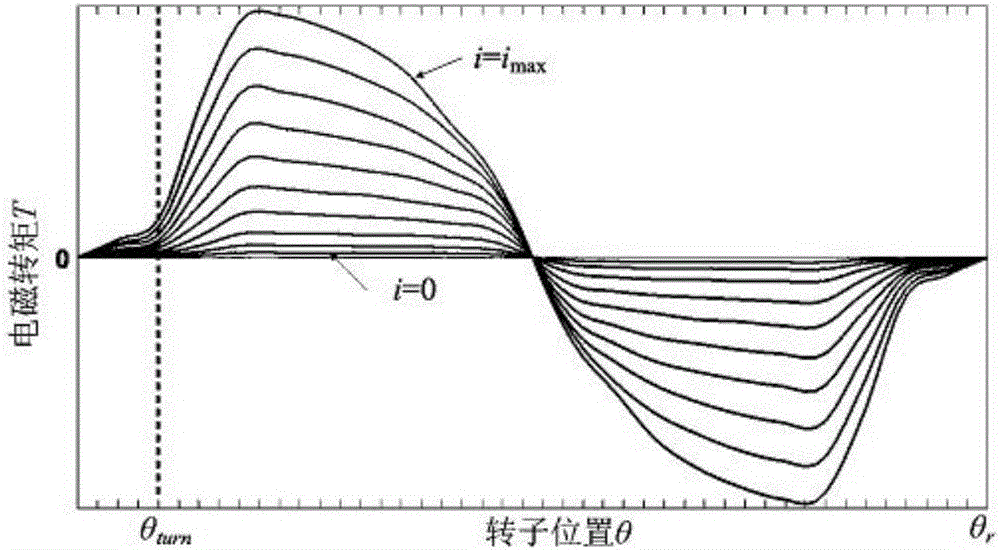

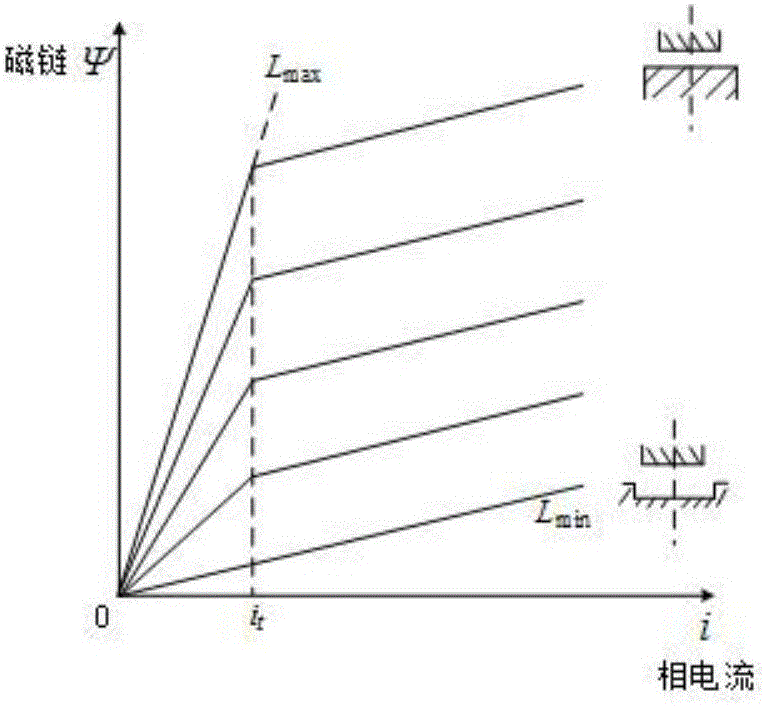

[0066] Step 1: Sectorize one rotor cycle of the m-phase switched reluctance motor: the number of motor phases is m≥3, and the rotor tooth pole pitch is θ r , that is, the mechanical angle rotated by one rotor cycle is θ r , the corresponding electrical angle is 360°, converted into a radian of 2π, and the step angle of the switched reluctance motor is θ r The electrical angle corresponding to / m is 2π / m.

[0067] For the ξ(1≤ξ≤m) phase of the motor, the two adjacent phases are ξ-1 and ξ+1. Suppose the running order is ξ-1→ξ→ξ+1, that is, ξ-1 represents the previous phase of ξ, and ξ+1 represents the next phase of ξ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com