Manufacturing method of plant resin specimen for teaching

A plant resin and production method technology, applied in the field of plant specimens, can solve the problems of not being able to protect plant pigments well, unable to make plant specimens, etc., and achieve the effect of wide and long-term use and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

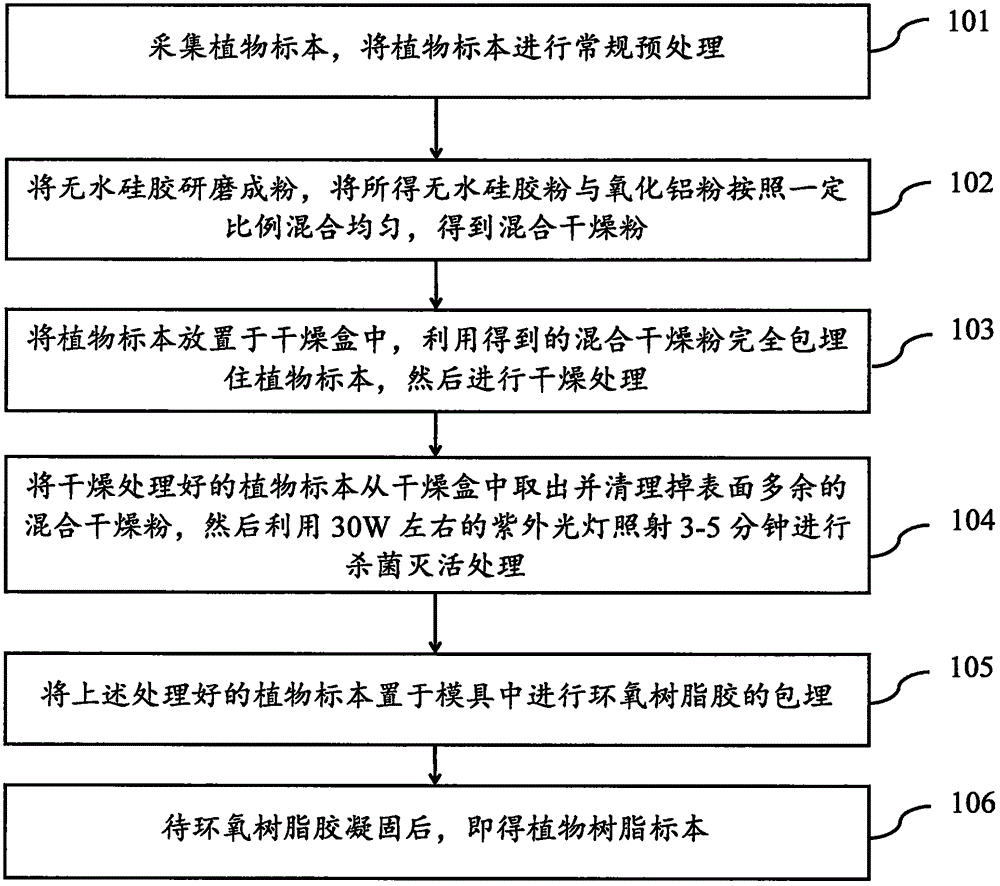

[0050] The teaching plant resin specimen of the embodiment of the present invention, preparation method is as follows:

[0051] Step 1, collect the green plants that need to be made into resin specimens as plant specimens, and perform conventional pretreatment on the collected plant specimens; the conventional pretreatment is to remove soil, decayed leaves and other dirt from the collected green plants, and trim to remove excess branches and leaves.

[0052] Step 2, preparation of dry powder: grind anhydrous silica gel into anhydrous silica gel powder that can pass through a 50-100 mesh screen, and then mix it with alumina powder at a mass ratio of 1:1.5 to obtain a mixed dry powder.

[0053] Step 3, placing the plant specimens in a drying box, using the obtained mixed dry powder to completely embed the plant specimens, and then drying them;

[0054] Embedding plant specimens with mixed dry powder is carried out as follows: spread 2 cm of mixed dry powder on the bottom of the...

Embodiment 2

[0065] The teaching plant resin specimen of the embodiment of the present invention, preparation method is as follows:

[0066] Step 1, collect the green plants that need to be made into resin specimens as plant specimens, and perform conventional pretreatment on the collected plant specimens; the conventional pretreatment is to remove soil, decayed leaves and other dirt from the collected green plants, and trim to remove excess branches and leaves.

[0067] Step 2, preparation of dry powder: grind anhydrous silica gel into anhydrous silica gel powder that can pass through a 50-100 mesh screen, and then mix it with alumina powder at a mass ratio of 1:3 to obtain a mixed dry powder.

[0068] Step 3, placing the plant specimens in a drying box, using the obtained mixed dry powder to completely embed the plant specimens, and then drying them;

[0069] The embedding of plant specimens with mixed dry powder is carried out as follows: spread 5cm of mixed dry powder on the bottom of...

Embodiment 3

[0080] The teaching plant resin specimen of the embodiment of the present invention, preparation method is as follows:

[0081] Step 1, collect the green plants that need to be made into resin specimens as plant specimens, and perform conventional pretreatment on the collected plant specimens; the conventional pretreatment is to remove soil, decayed leaves and other dirt from the collected green plants, and trim to remove excess branches and leaves.

[0082] Step 2, preparation of dry powder: grind anhydrous silica gel into anhydrous silica gel powder that can pass through a 50-100 mesh screen, and then mix it with alumina powder at a mass ratio of 1:2 to obtain a mixed dry powder.

[0083] Step 3, placing the plant specimens in a drying box, using the obtained mixed dry powder to completely embed the plant specimens, and then drying them;

[0084] The embedding of plant specimens with mixed dry powder is carried out as follows: spread 3 cm of mixed dry powder on the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com