Large-sized methane solid fermentation apparatus and usage thereof

A technology of solid-state fermentation and biogas collection device, which is applied to solid-phase fermentation bioreactors, methods of supporting/immobilizing microorganisms, fermentation, etc., can solve the problems of inconvenient discharge, difficult construction, and inconvenient feeding, and achieve The effect of alleviating resistance, reducing investment, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

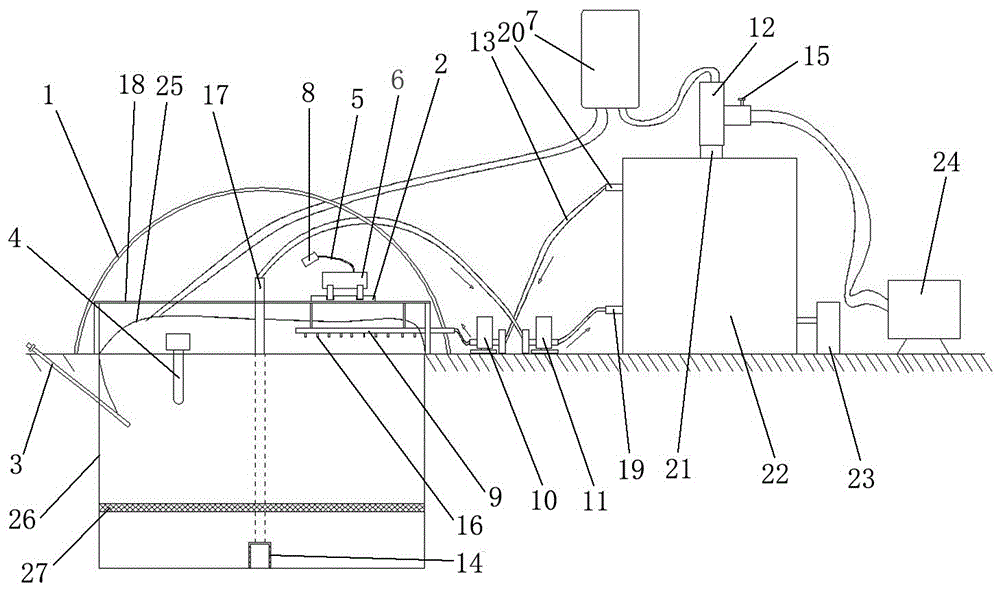

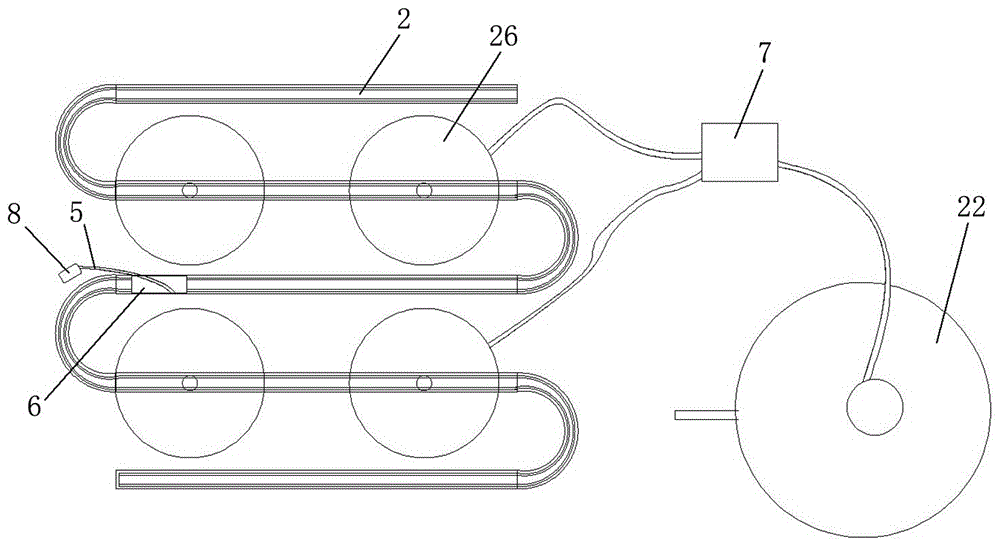

[0027] see figure 1 and figure 2, a large-scale biogas solid-state fermentation device, including a fermentation area and a UASB reactor 22 arranged on one side of the fermentation area, the UASB reactor 22 includes a reactor body, and reactor rows are respectively arranged on the top of the reactor body Gas port 21 and reactor liquid outlet 20, the bottom is provided with reactor liquid inlet 19, and the inside is provided with three-phase separator; Described fermenting area comprises the many groups of fermenting tanks built in the ground, and each group of fermenting tanks comprises several groups of fermenting tanks covered with The fermentation tank 26 of the light-transmitting shed 1, the fermentation tank 26 is cylindrical, and the center is provided with a pipeline-type column 17, the upper end of the column 17 stretches out from the upper part of the fermentation tank 26, and the lower end extends into the bottom of the fermentation tank 26, And the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com