Production device for compacted strand steel wire rope and production method of production device

A technology for producing equipment and steel wire ropes, which is applied to auxiliary equipment for rope making, textiles, papermaking, textile cables, etc. and other problems, to achieve the effect of less damage to mechanical properties, simple and convenient production process, and improved breaking force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

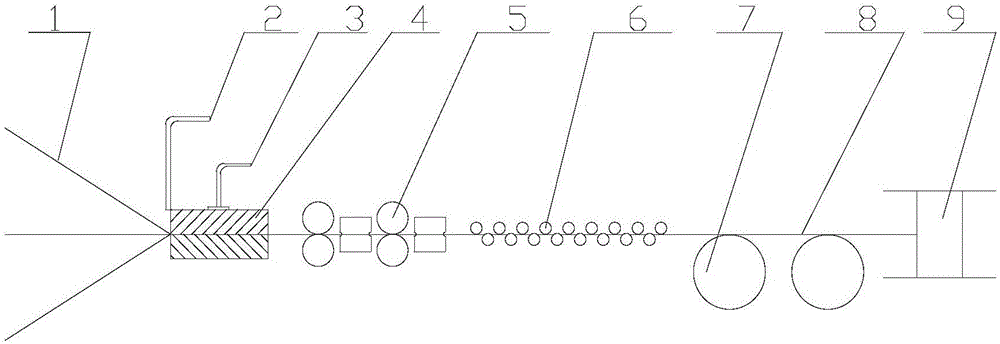

[0028] In order to achieve the purpose of the present invention, as figure 1 As shown, in one of the embodiments of the present invention, a production device for compacted strand steel wire rope is provided, including a strand twisting device, an oil injection device 2, a crimping die 4, a first deformation mechanism, and a second deformation Mechanism and wire take-up device 9, the fuel injection device is arranged at the closing mouth of the twisting device, the first deformation mechanism includes four roll groups 5 arranged in sequence along the wire rope advancing direction, and the upper and lower rolls of each roll group 5 form an axial through hole;

[0029] The second deformation mechanism includes eight pairs of second deformation pulley blocks 6 and second traction pulleys 7 arranged in sequence along the advancing direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com