Gas-liquid two-phase flow performance testing system and method for centrifugal pump

A test system and centrifugal pump technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve the problem of blocked flow channels, inoperable centrifugal pumps, and difficulty in establishing a test pump test system for simulating gas-liquid two-phase flow. and other problems, to achieve the effect of easy disassembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

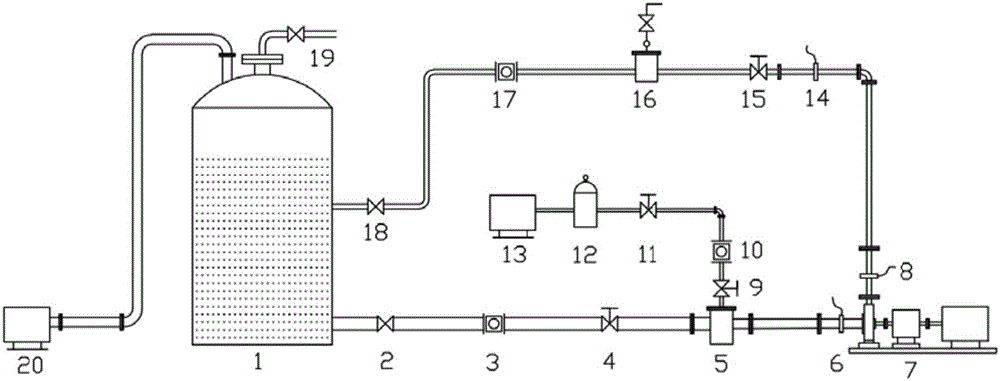

[0049] Such as figure 1As shown, the pump test system of the present invention is a closed circulation loop mainly composed of liquid storage tank 1, inlet pipeline, intake pipe branch, frequency conversion pump unit 7 and outlet pipeline. The outlet pipeline is connected to the outlet end of the frequency conversion pump unit 7, and the inlet end of the frequency conversion pump unit 7 is connected to the outlet at the bottom of the liquid storage tank 1 through the inlet pipeline, and the inlet pipeline is also connected with an intake pipe branch.

[0050] Two pipes are connected above the liquid storage tank 1, one is connected with an exhaust valve 19 to discharge excess air in the tank; the other is connected with a vacuum pump 20 for vacuumizing the liquid in the tank. The entire liquid storage tank 1 is isolated from the outside air. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com