All-frequency-band working-condition self-adaptive hydraulic filter

A filter and self-adaptive technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve poor adaptability to changing working conditions, influence of filtering effect, flow pulsation without filtering, etc. problem, to achieve good flow pulsation attenuation efficiency, broaden the attenuation frequency bandwidth, and the effect of large resonance cavity volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

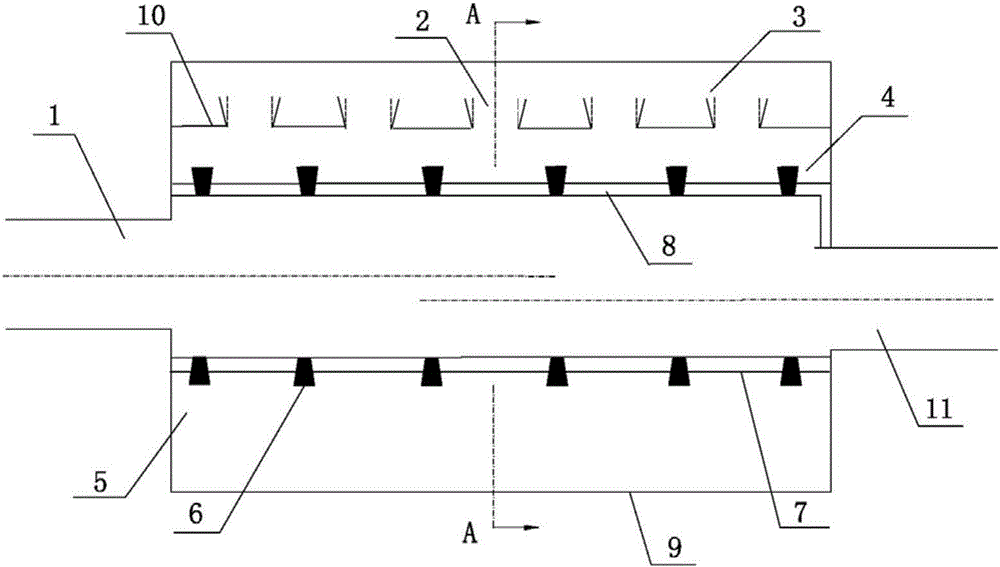

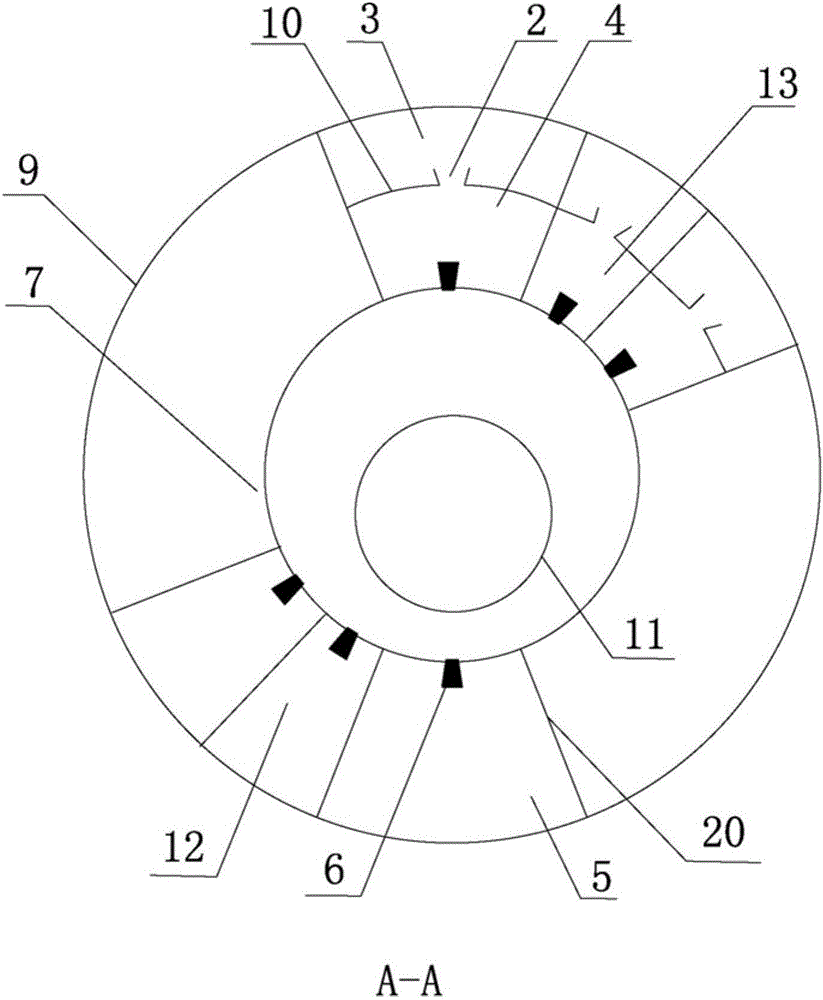

[0028] Please refer to the attached figure 1 to attach Figure 9 As shown, the present invention is a full-band working condition adaptive hydraulic filter, which consists of an input pipe 1, a casing 9, an output pipe 11, an elastic thin wall 7, a plug-in H-type filter 12 and a plug-in series H-type filter Several parts such as device 13 are formed.

[0029] Wherein, the input tube 1 is connected to one end of the shell 9 ; the output tube 11 is connected to the other end of the shell 9 . The elastic thin wall 7 is installed inside the casing 9 along the radial direction of the casing. The axes of the input pipe 1 and the output pipe 11 are not on the same axis, which can improve the filtering effect by more than 10%.

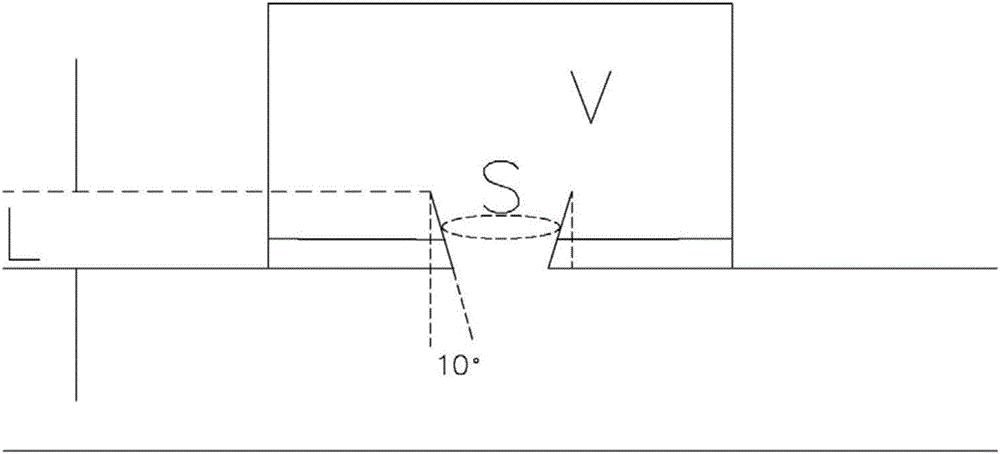

[0030] The input pipe 1 , output pipe 11 and elastic thin wall 7 jointly form a C-shaped cavity filter, thereby attenuating high-frequency pressure pulsation of the hydraulic system. The filter transmission coefficient obtained after processing according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com