A method for reducing noise, reducing vibration and saving energy by boiling in nucleated pool

A nucleate boiling and noise reduction technology, applied in lighting and heating equipment, heat transfer modification, instruments, etc., can solve problems such as no effective solution, environmental noise pollution, unfavorable rapid heat conduction, etc., to reduce the separation diameter, Enhance heat transfer and increase the effect of gasification core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

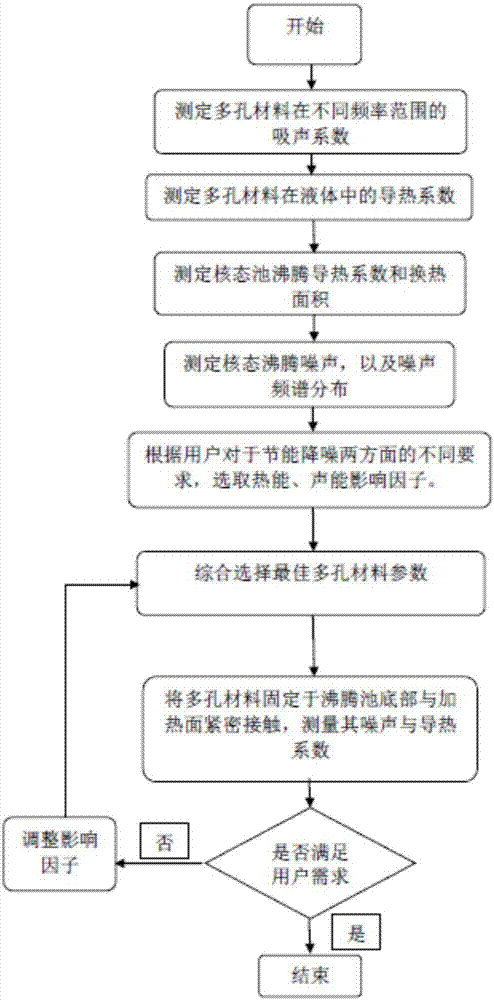

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] see figure 1 , the present invention comprises the following steps:

[0025] A. Determination of the sound absorption coefficient α of porous materials in different frequency ranges. It is necessary to comply with the specifications when conducting the test. The tested frequencies are 250Hz, 500Hz, 1000Hz, 2000Hz, 4000Hz, 6000Hz, and 10000HZ. The sound absorption coefficients of porous materials with different porosity P at different frequencies are obtained.

[0026] B. Determination of the thermal conductivity λ of the porous material in the boiling pool liquid 1 .

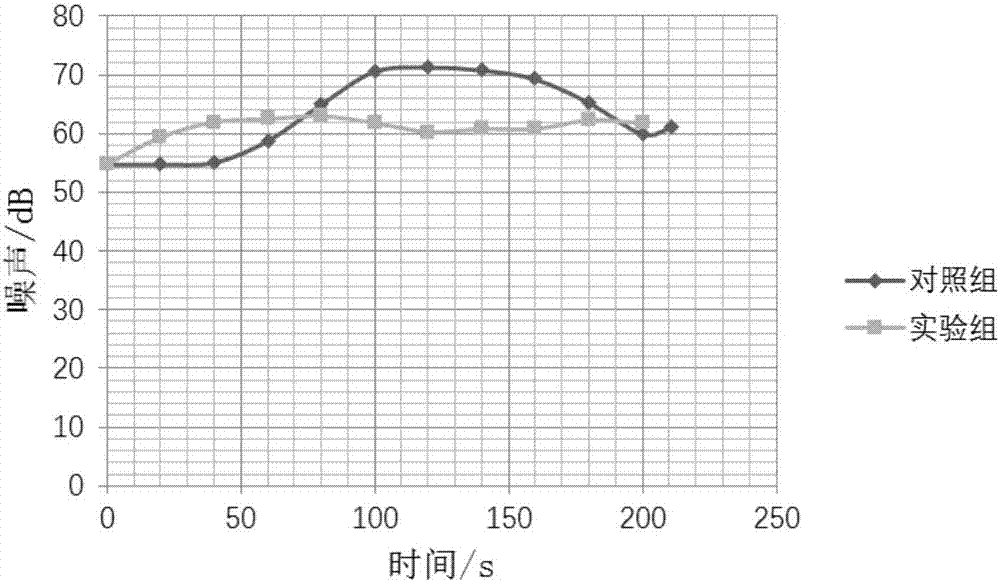

[0027] C. Determination of nucleate boiling noise L p , to measure ambient noise The boiling noise is corrected by using the environmental noise, and the frequency analysis diagram of the noise is obtained. True nucleate boiling noise It needs to be corrected for ambient noise, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com