Method for detecting defects in a piston for an internal combustion engine

A technology for internal combustion engines and pistons, applied in the field of defect measurement devices, can solve problems such as specific detection of defects that hinder small size, complex aperture characteristics of sensors, and defect detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

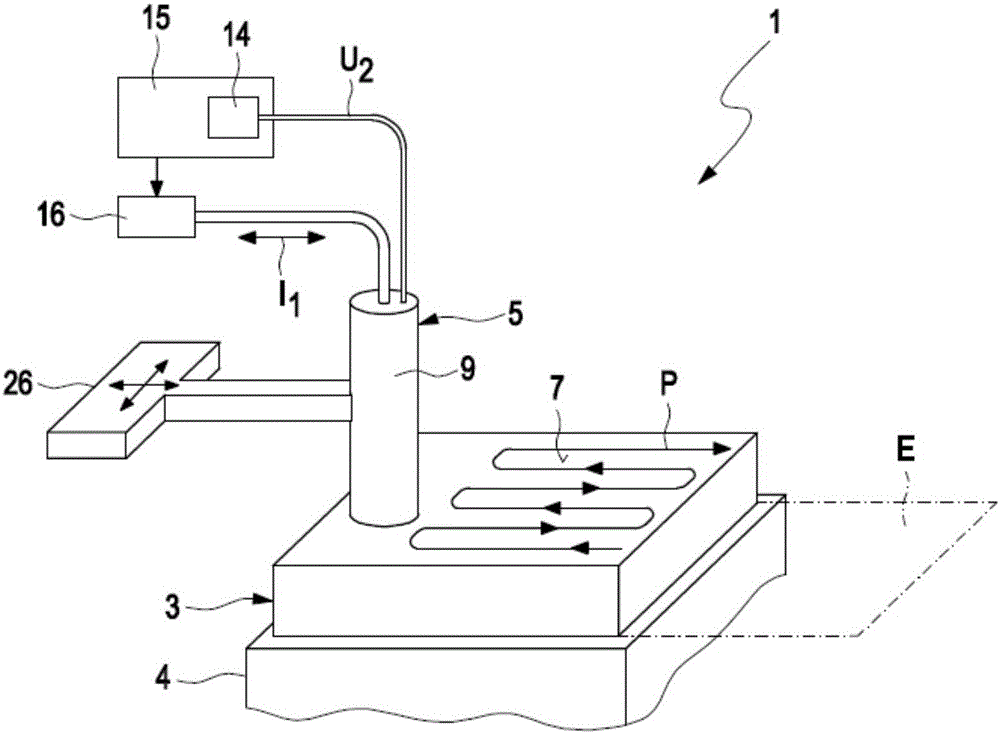

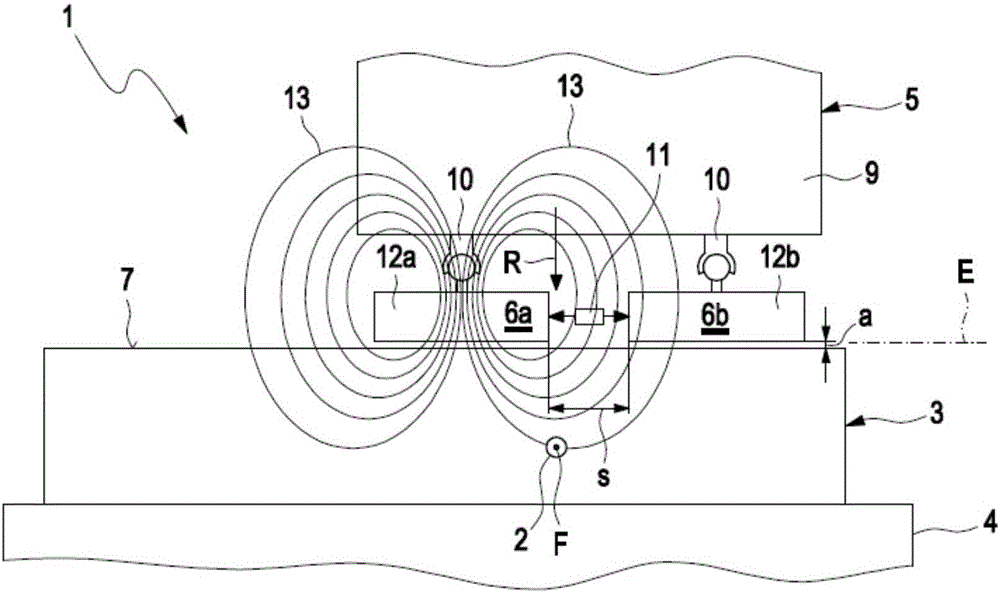

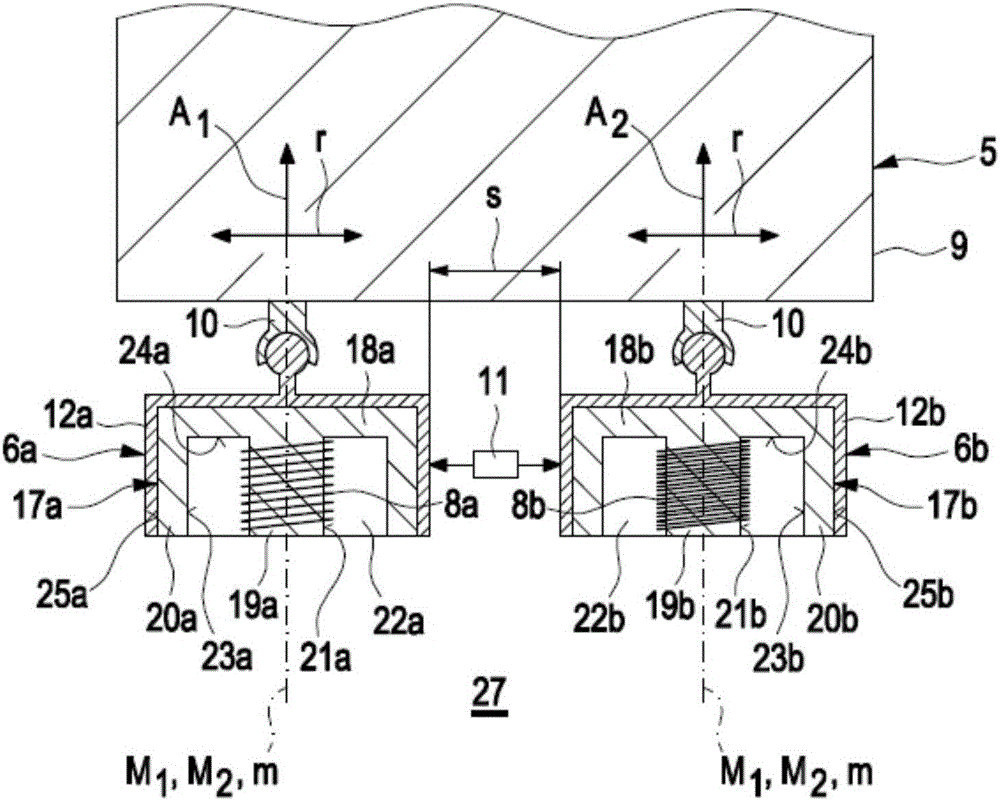

[0035] figure 1 A schematic diagram showing the use according to the invention for detecting the piston 3 in an internal combustion engine - only in figure 1 An example of a measuring device 1 for a defect 2 is shown in highly schematic form in . The measuring device 1 is particularly suitable for carrying out the above-discussed method according to the invention. The measuring device 1 comprises a receiving device 4 for receiving a piston 3 . The receiving device may be in the form of a fixture device, or as figure 1 Formed in the form of a sample stand indicated in high schematic form in middle. The measuring device 1 further comprises a measuring probe 5 which is figure 1 is likewise only highly schematically depicted and accordingly includes a first and a second coil element 6a, 6b for generating and detecting an electromagnetic alternating magnetic field.

[0036] figure 2 is the area of the measuring probe 5 from the measuring device 1 . It can be seen that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com