Gas distribution method and gas distribution device for checking SF6 (sulfur hexafluoride) analyzer

A sulfur hexafluoride and analyzer technology, which is applied to the analysis of gas mixtures, measuring devices, and analysis materials, can solve the problems of easy introduction of other impurities, cumbersome operation, and low accuracy, so as to achieve excellent gas distribution efficiency and improve calibration Proven efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

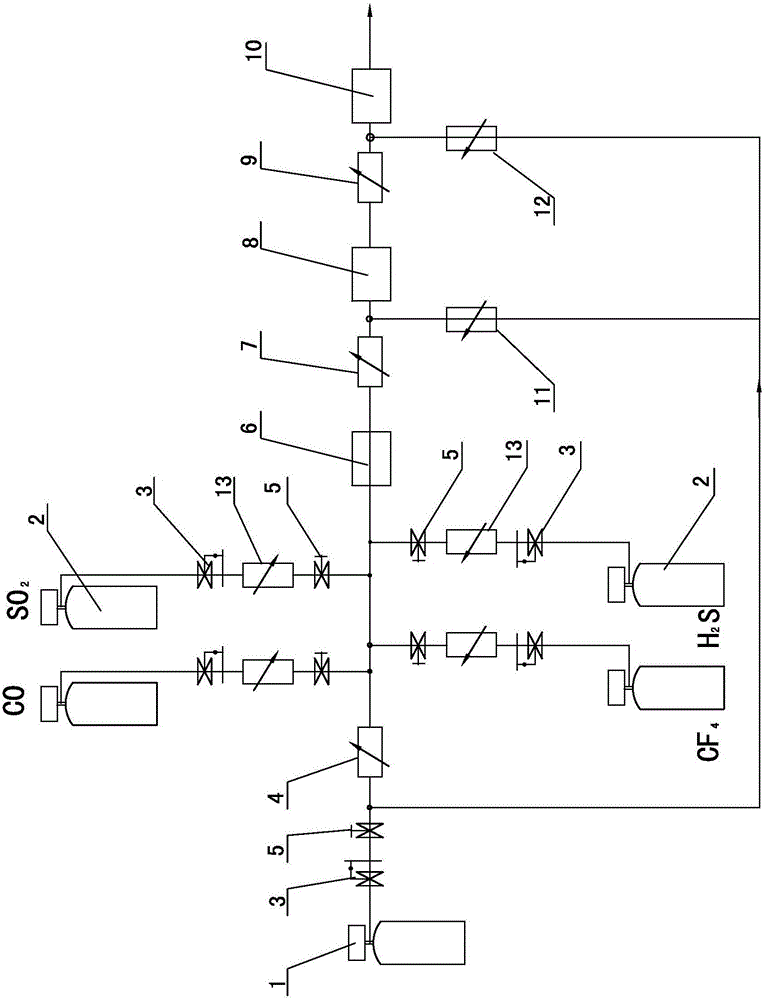

[0017] The content of the present invention will be further described in detail through the following examples. exist figure 1 In the shown example: sample gas cylinder 2 has SO 2 Cylinder, H 2 Cylinders for 4 gases including S cylinders. Main air path slave connection SF 6 The output end of the gas cylinder 1 is initially provided with a pressure reducing valve 3, a solenoid valve 5, a first mass flow controller 4, a first static mixer 6, a second mass flow controller 7, a second static mixer 8, The third mass flow controller 9 and the third static mixer 10, SF 6 The output end of gas cylinder 1 is also connected to the main gas path between the second mass flow controller 7 and the second static mixer 8 through the solenoid valve 5 on the main gas path and the branch gas path provided with the fourth mass flow controller 11 , through the electromagnetic valve 5 on the main gas circuit and the branch gas circuit provided with the fifth mass flow controller 12 connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com