Elevator inspection, simulation, training and examination system

A simulation training and elevator technology, applied in instruments, simulators, space navigation equipment, etc., can solve problems such as impact, low safety, and unfair inspection results, achieve high safety, improve efficiency, and improve objectivity and fairness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

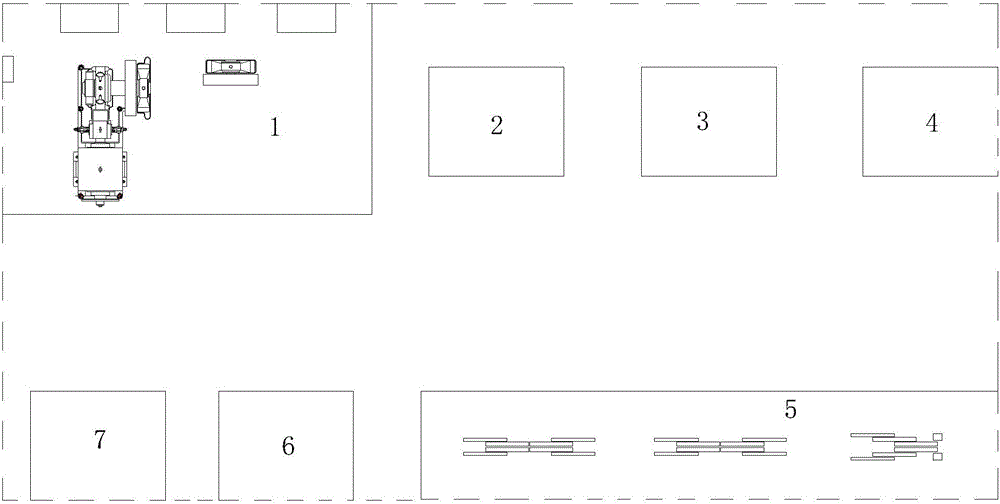

[0022] A set of adjustable dimensions and related parameters of the equipment elevator structure, setting different fault defect points, providing an elevator inspection simulation training assessment system, including the machine room area 1, the pit area 2, the car top area 3, the model area 4, the door Area 5, car area 6 and operation monitoring and assessment system 7, equipment and models in each area of machine room area 1, pit area 2, car top area 3, model area 4, door area 5, and car area 6, through travel switches , control switch and other devices collect the running status signal and control signal, and at the same time collect the assessment status signal and the dimensional parameters that need to be measured through the position sensor and displacement sensor. The collected running status signal, control signal, assessment status signal, The size parameters are fed back to the operation monitoring and assessment system 7 through the control circuit, and displaye...

Embodiment 2

[0024] A set of special system that can satisfy the training and assessment of elevator inspectors according to the relevant content of national elevator inspection regulations, provides an elevator inspection simulation training and assessment system, including machine room area 1, bottom pit area 2, car top area 3, model area 4, Door area 5, car area 6, and operation monitoring and assessment system 7. The examiner before the student assessment can set the initial failure point on the monitoring and assessment system interface in the operation monitoring and assessment system 7 according to different assessment needs. In the inspection of equipment and models in each area, find the initial fault points and measure the corresponding size parameters, and within a specific time, the students will complete the answers on the monitoring and assessment system interface, and automatically judge according to the input results of the students, and complete the evaluation of the student...

Embodiment 3

[0026] A set of elevator inspection training and assessment system combining equipment, model and simulation, equipment, model and operation monitoring system are synchronized, providing an elevator inspection simulation training and assessment system, including machine room area 1, bottom pit area 2, car top area 3, The model area 4, the door area 5, the car area 6, and the operation monitoring and assessment system 7. The operation monitoring and assessment system 7 controls the equipment and models in each area to perform joint operation under the condition of ignoring failures and failures according to the elevator control principle. The interface of the operation monitoring system Carry out synchronous animation demonstrations. The students being assessed need to find out the initial fault points during the inspection of the equipment and models in each area, measure the corresponding size parameters at the same time, and complete the answers on the monitoring and assessmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com